Chemical vapor deposition equipment, ceramic heating disc and preparation method of ceramic heating disc

A technology of ceramic heating and heating plate, which is applied in gaseous chemical plating, coating, metal material coating process, etc., can solve the problem that the uniformity of heat conduction efficiency of wafer heating needs to be improved, and achieves simple and easy resistance setting, The effect of stable connection and reducing interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

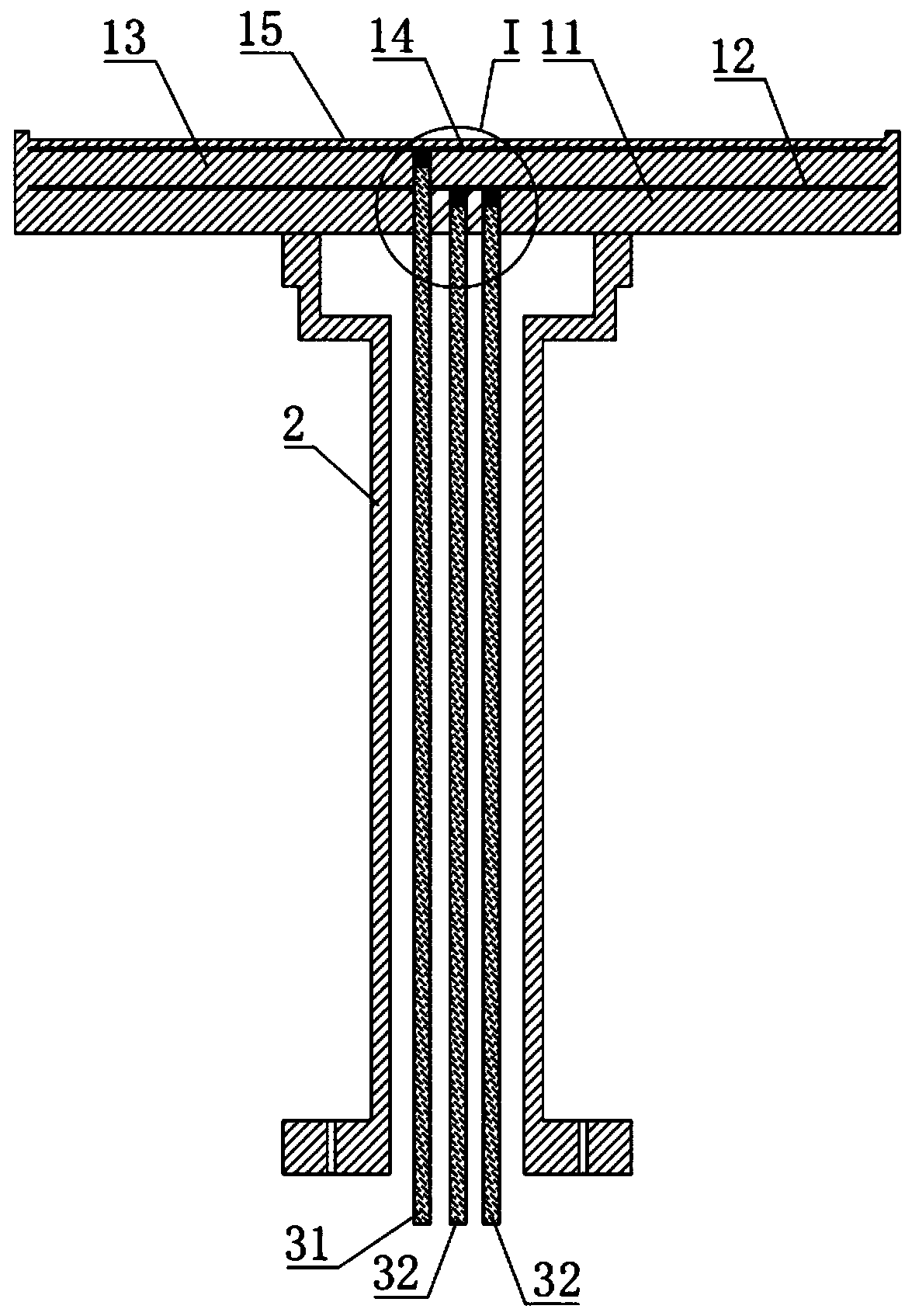

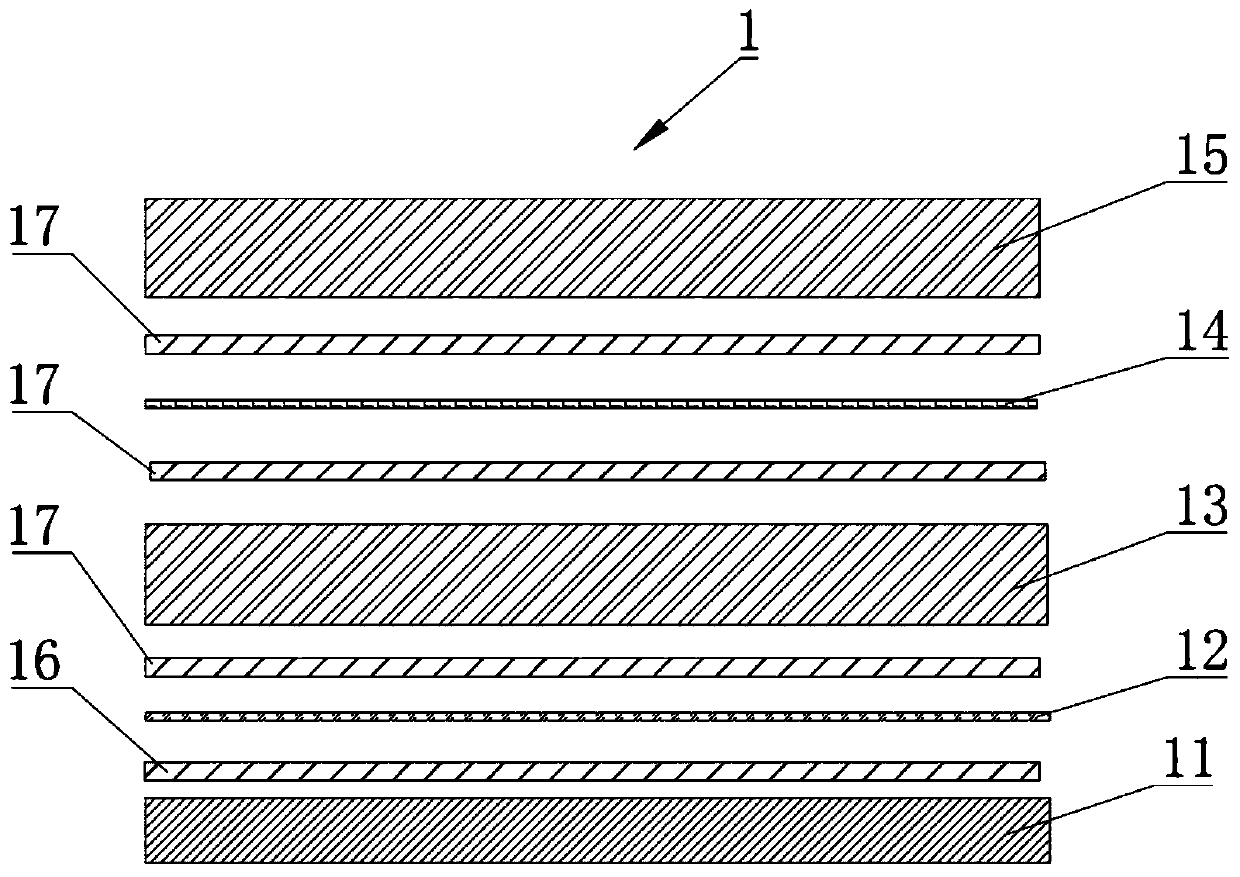

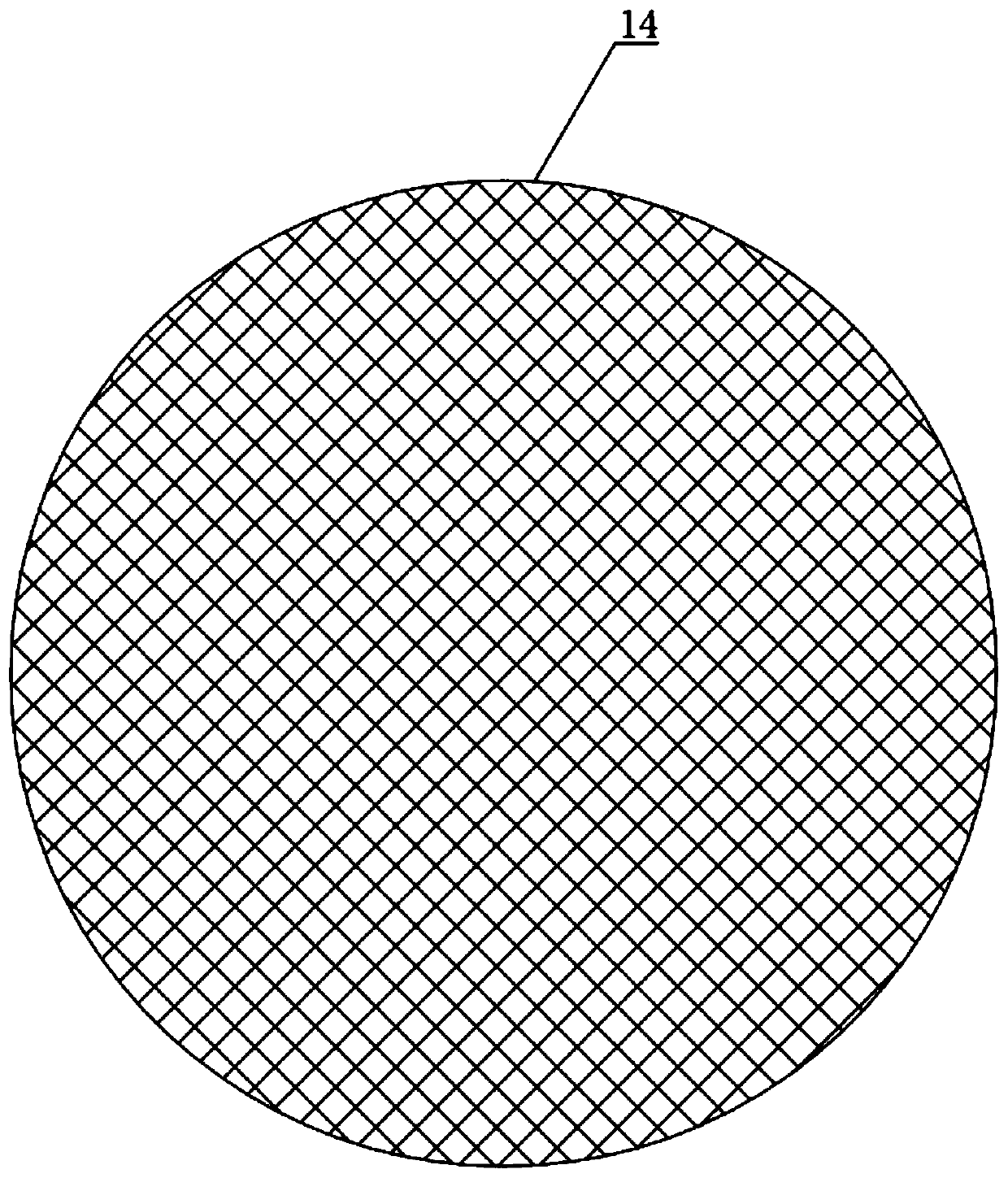

[0072] The specific embodiments of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solution of the present invention and its advantages in various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

[0073] The "connection" mentioned in the present invention should be interpreted in a broad sense unless otherwise specified or limited, and may be a direct connection or a connection through an intermediary. In the description of the present invention, it should be understood that the directions or positions indicated by "upper", "lower", "front", "back", "left", "right", "top", "bottom" etc. The relationship is based on the orientation or positional relationship shown in the drawings, and is only for the convenience of describing the present invention and simplifying the description, ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com