Positioning structure of carpentry machining center

A positioning structure, processing center technology, applied in wood processing appliances, manufacturing tools, special forming/shaping machines, etc., can solve problems such as poor positioning stability, and achieve high positioning stability, flexible use, and improved positioning stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

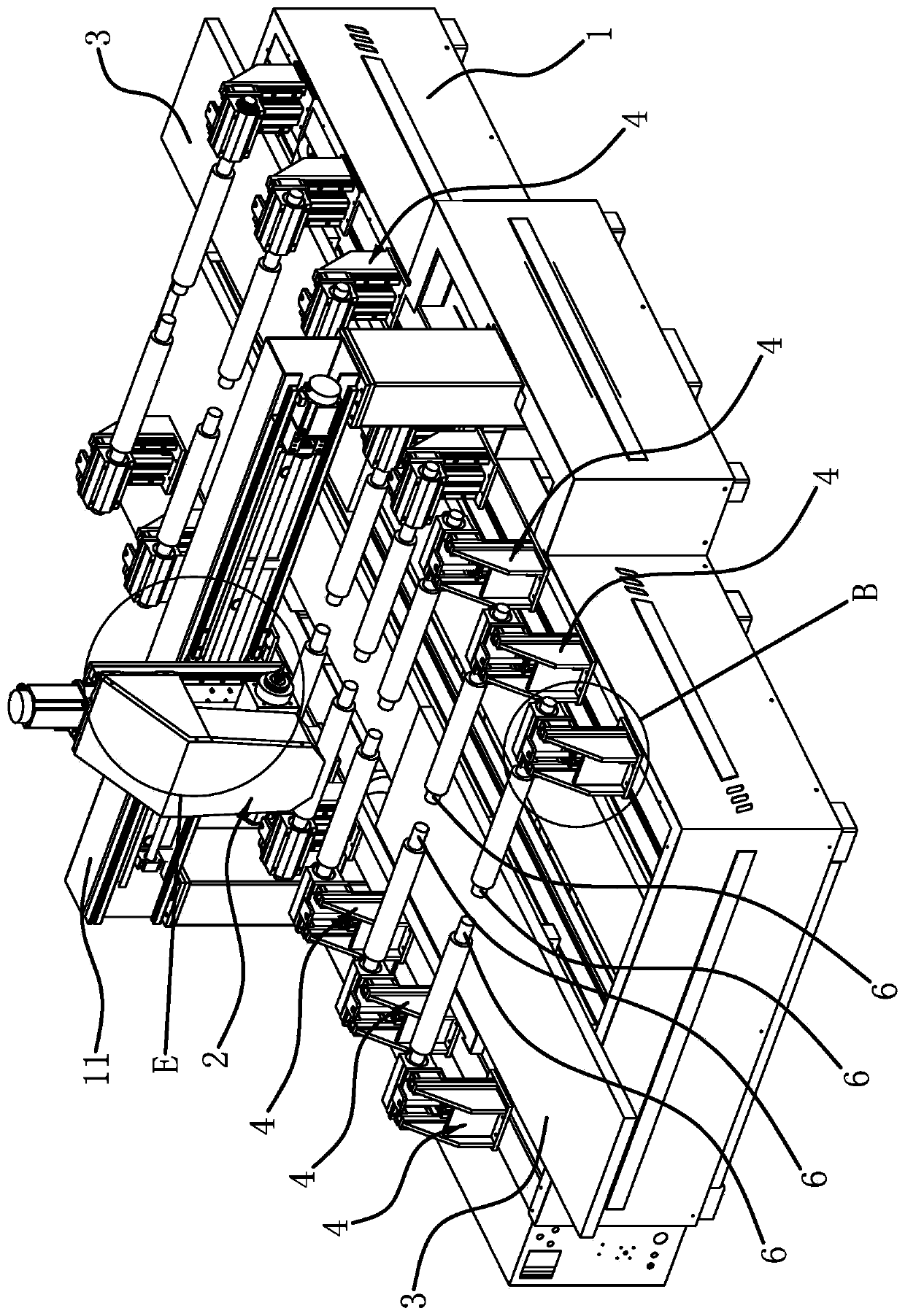

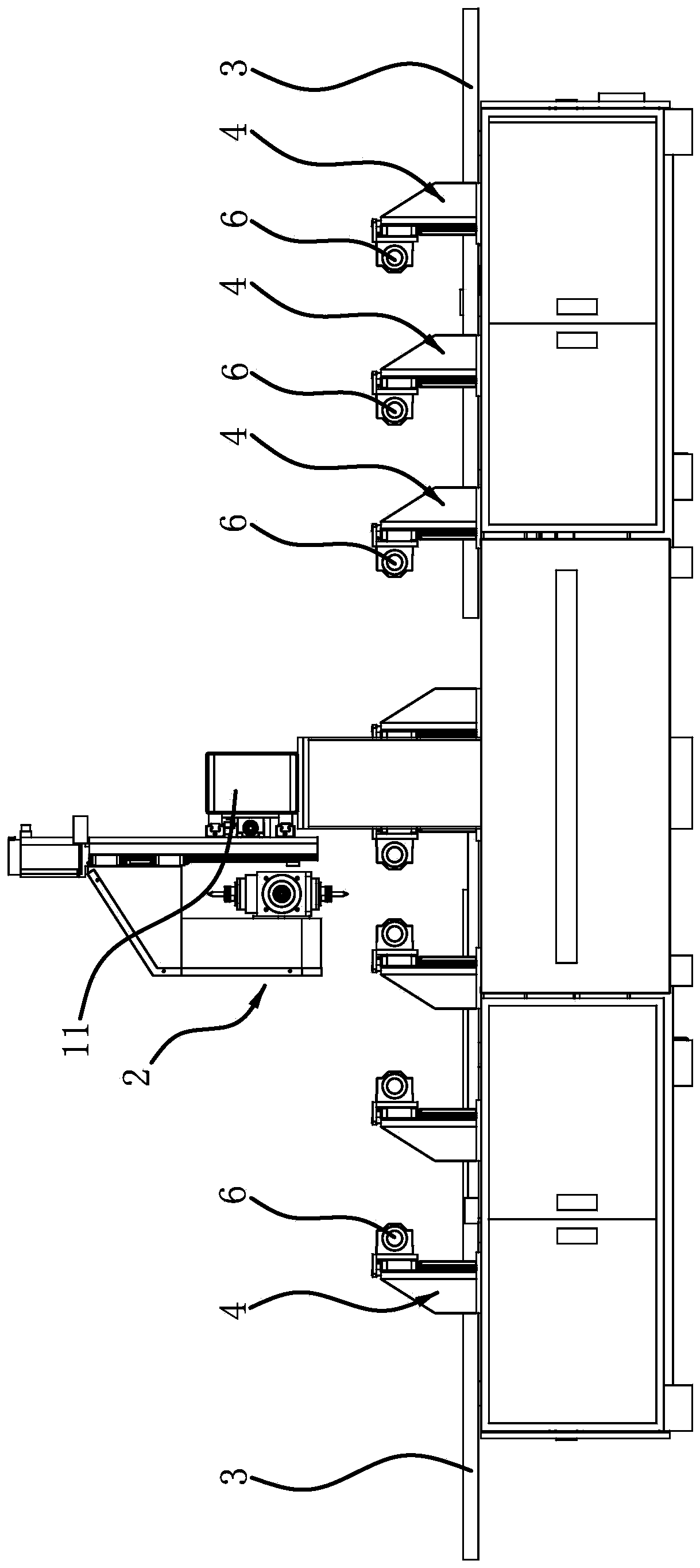

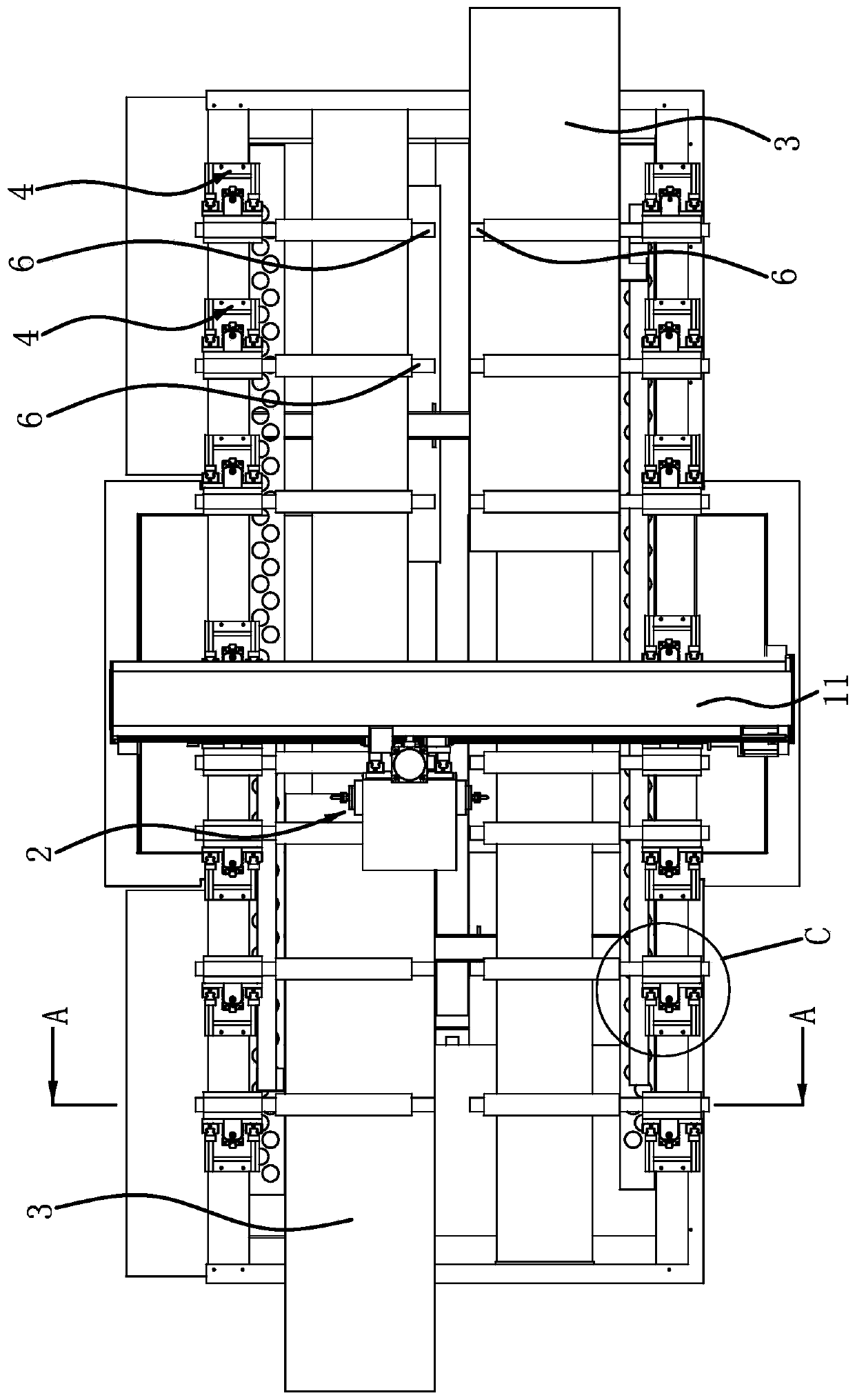

[0034] Such as Figure 1 to Figure 4 As shown, the positioning structure of the woodworking processing center, the woodworking processing center includes a frame 1 and a crossbeam 11, vertical columns are fixed on both sides of the longitudinal middle of the frame 1, the crossbeam 11 is arranged horizontally, and the two ends of the crossbeam 11 are respectively fixed At the top of the two columns, on one side of the beam 11, the processing assembly 2 is connected with the horizontal carriage 8 and the vertical carriage 9, and the movement of the horizontal carriage 8 and the vertical carriage 9 realizes the horizontal movement and the vertical movement of the processing assembly 2 , and on the frame 1, there are two processing platforms 3 longitudinally slidably connected. The two processing platforms 3 are strip-shaped and arranged longitudinally for placing workpieces. Therefore, three-dimensional translation can be realized between the processing assembly 2 and the process...

Embodiment 2

[0038] The positioning structure of this woodworking processing center is basically the same as that of Embodiment 1, the difference is that Figure 9 , Figure 10 As shown, an adjusting plate 55 is fixed on the lifting seat 5, and the adjusting plate 55 is connected to the lifting plate 52 by rotating the rotating disk 56, so that the positioning pressure roller 6 can swing in the vertical plane, and the adjusting plate 52 is vertically fixed on the lifting plate 52 Cylinder 57, the piston rod of the adjustment cylinder 57 is vertically downward, and one side edge of the adjustment plate 55 has a protruding adjustment part 551, the adjustment part 551 is in the shape of a strip plate, and the adjustment part 551 is arc-shaped along the length direction And arched upwards, the adjustment part 551 is provided with a strip hole 552 along the length direction, and the piston rod end of the adjustment cylinder 57 has a stepped surface 571 in the circumferential direction, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com