Linear bearing

A technology of linear bearings and balls, which is applied in the direction of linear motion bearings, bearings, shafts and bearings, and can solve problems such as linear bearings stopping working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

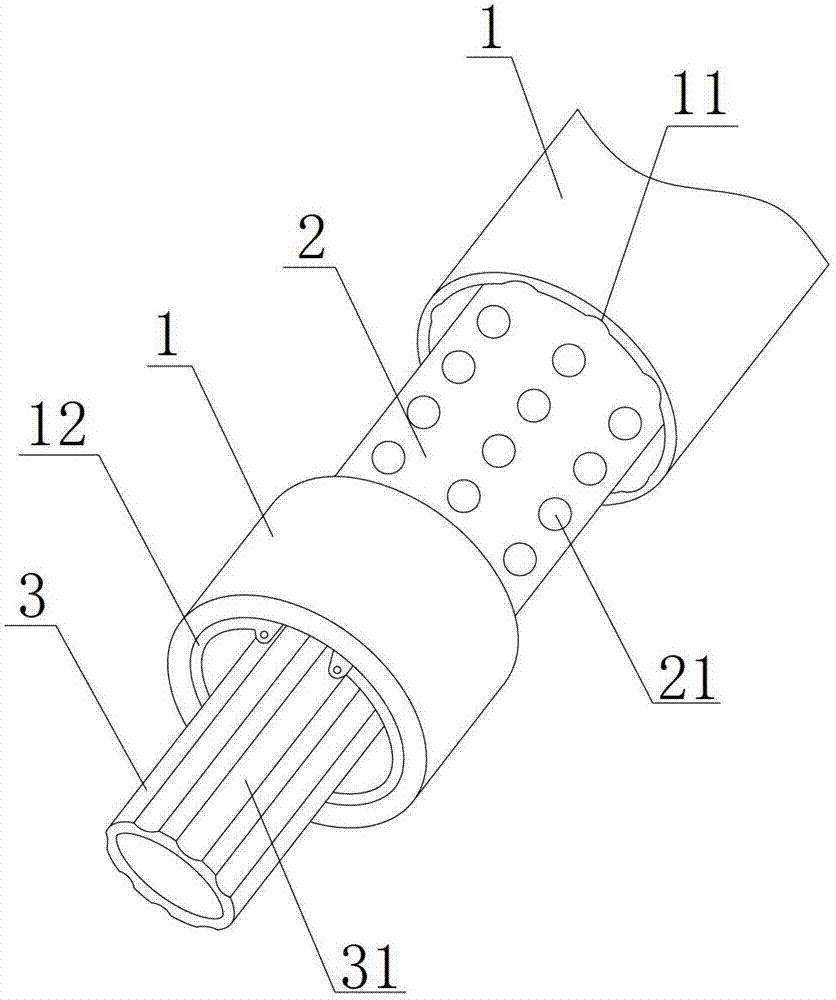

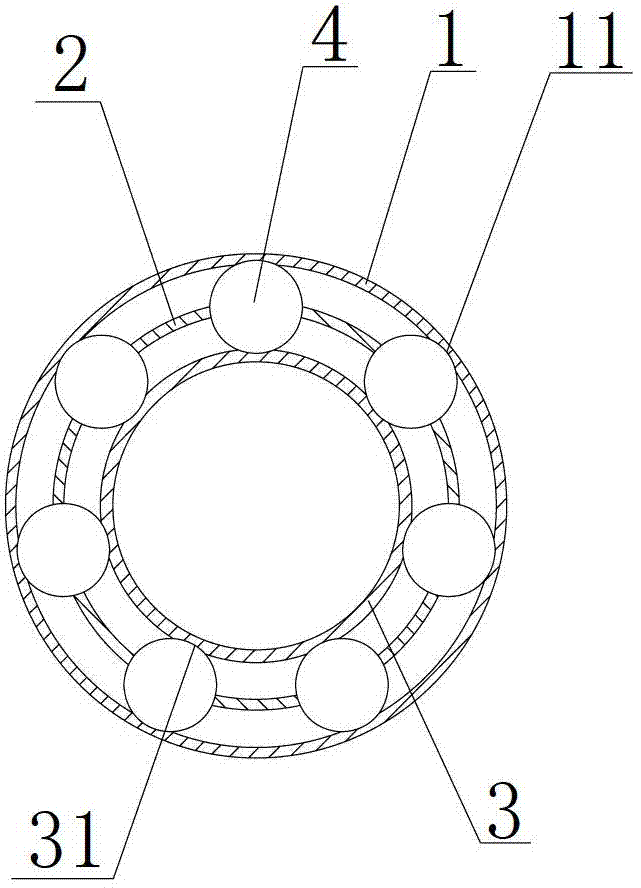

[0016] Such as figure 1 and figure 2 Commonly shown is an embodiment of the linear bearing of the present invention, in order to explain the present invention more clearly, in figure 1 A section of the outer ring 1 is cut off to expose the cage 2, and the ball 4 is not shown. In addition, in the actual use process, the end of the outer ring 1 is provided with a retaining ring 12, which can not only play a role in sealing and lubricating The effect of the oil can prevent the cage 2 from protruding from the end of the outer ring 1, and the inner ring 3 will not protrude from the end of the cage 2. In the figure, a part of the inner ring 3 is only for the convenience of illustration. Out of the end of the cage 2. The foregoing are all known technologies in the technical field, and will not be repeated here.

[0017] This embodiment includes an inner ring 3, a cage 2, and an outer ring 1 that are fitted together from inside to outside, wherein, on the cage 2, there are a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com