Automatic film pasting equipment for surface of semiconductor wafer

A film laminating equipment and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as wafer damage, bubble residue, and poor bubble extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

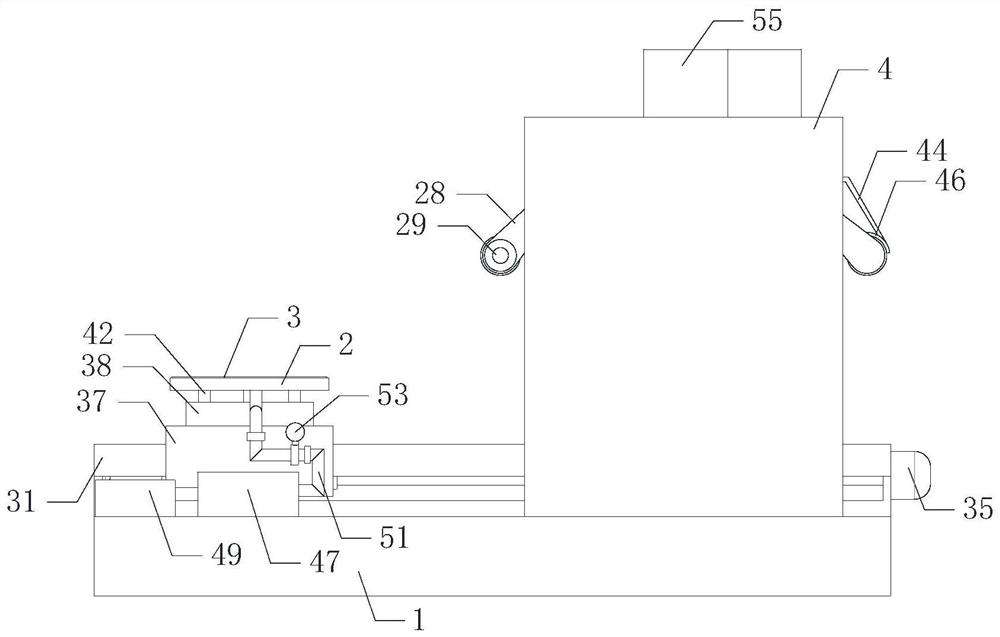

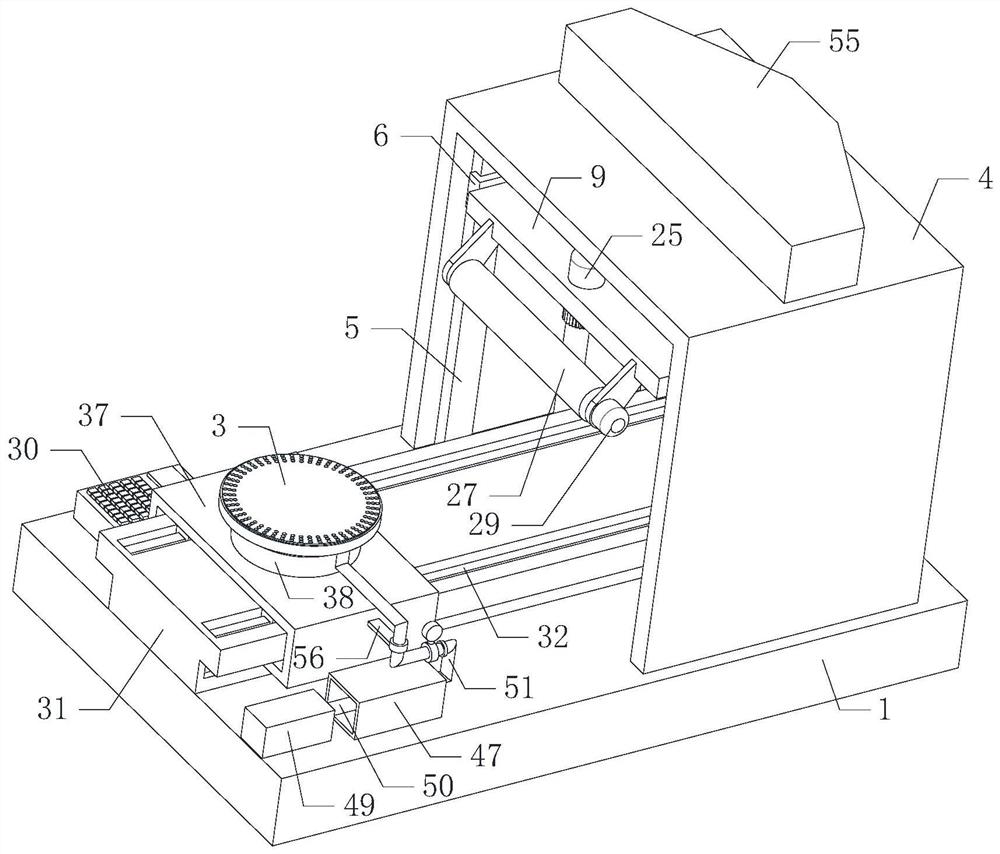

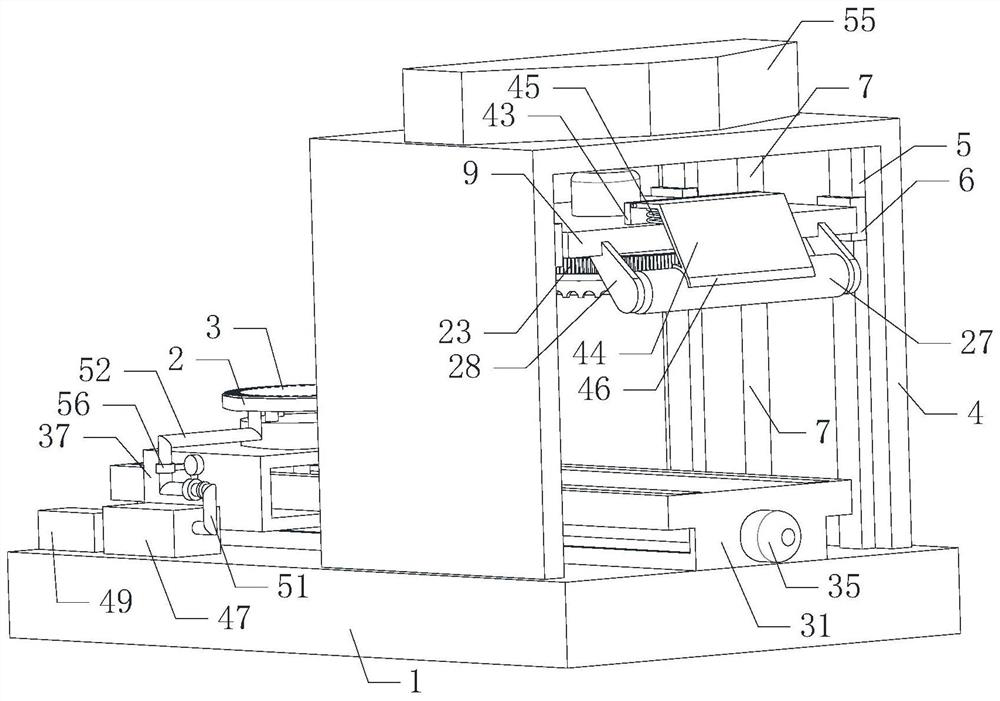

[0023] Such as Figure 1 to Figure 8As shown, the semiconductor wafer surface automatic film sticking equipment of the present invention, when it is working, the protruding end of the winding film on the right winding roller 27 is wound on the left winding roller 27, so that the bottom of the pressure ring 21 is covered with film, the wafer is placed on the rubber pad 3, the position of the wafer is aligned with the position of the circular adsorption chamber 2, the central control box 30 controls the opening of the suction device, and the suction device sucks the air in the circular adsorption chamber 2 Negative pressure is formed inside the circular adsorption chamber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com