Full-automatic lens producing and processing equipment

A kind of processing equipment, fully automatic technology, applied in the direction of metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of easy placement deviation of the lens, easy crushing of the lens, damage to the lens, cumbersome operation, etc., to avoid crushing damage, easy operation, and improved automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

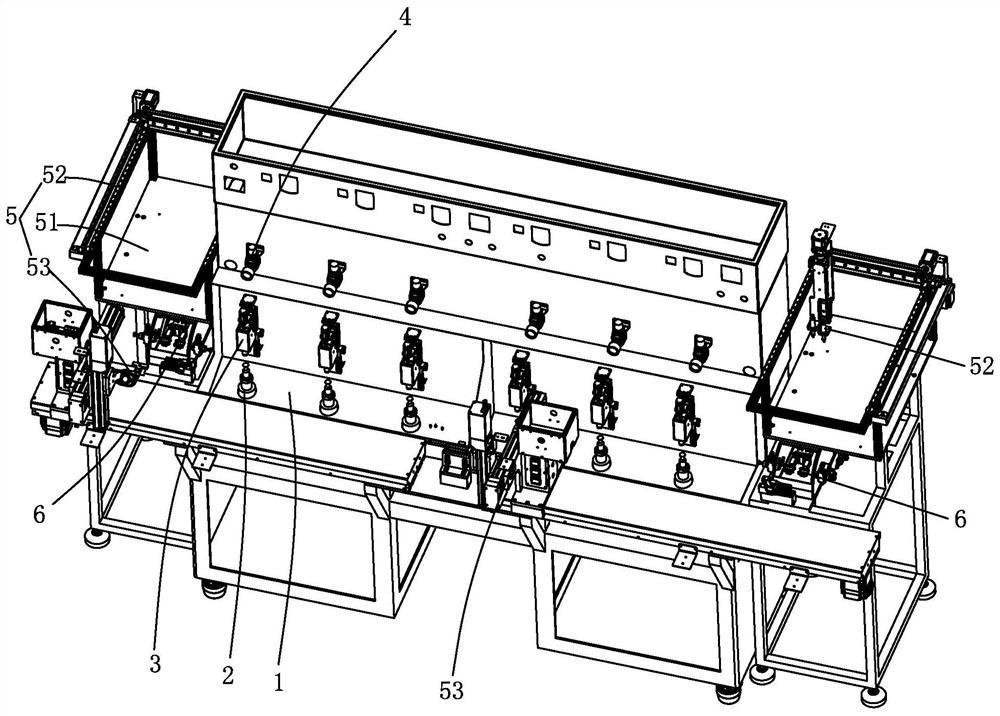

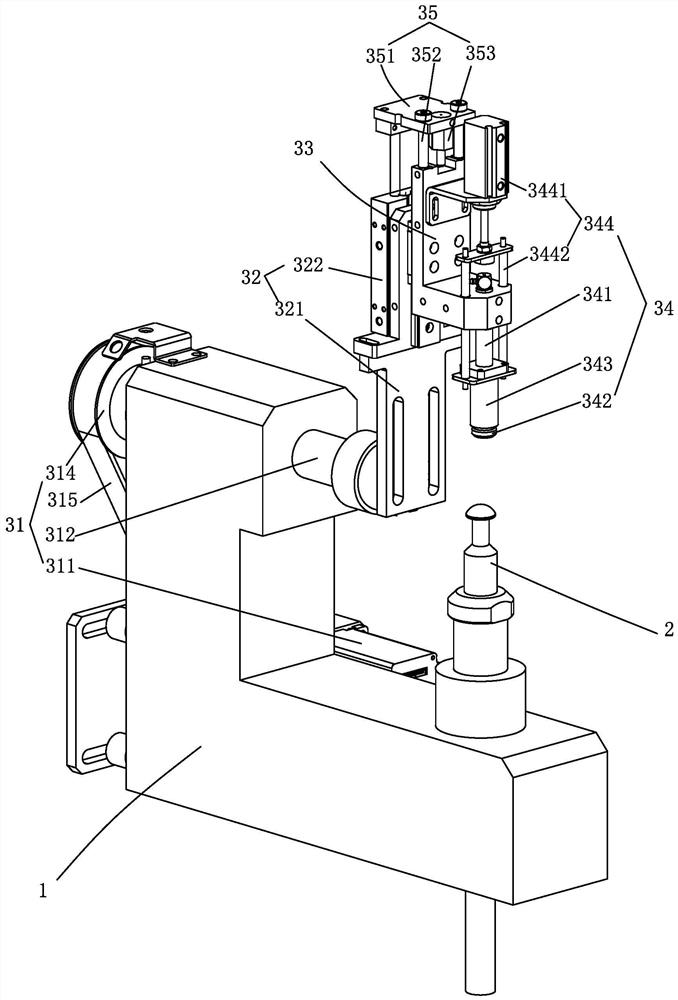

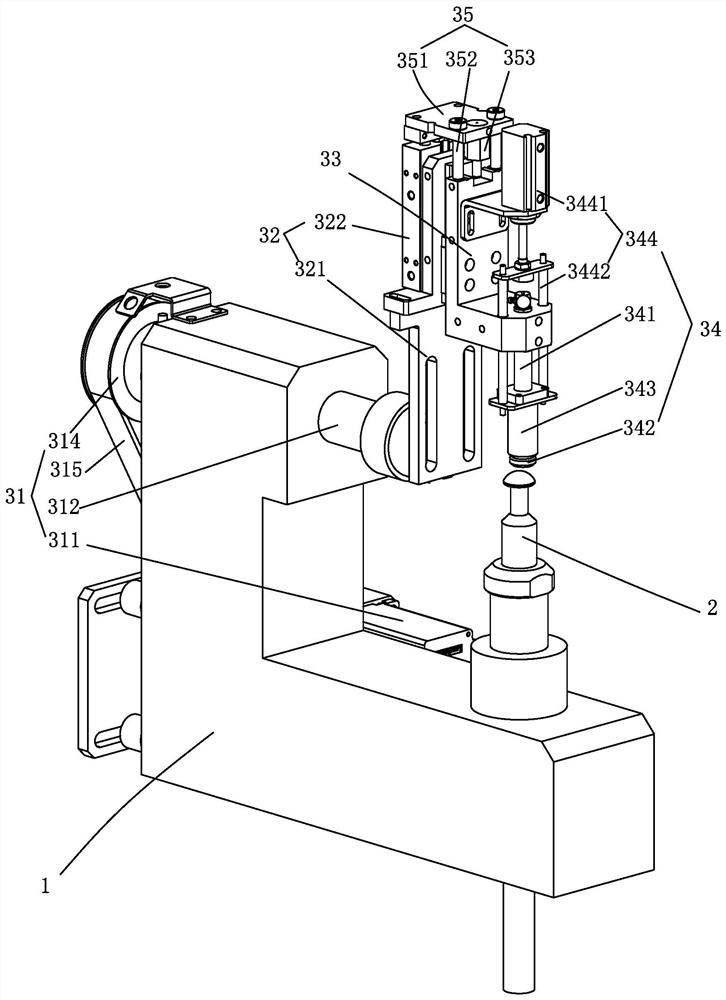

[0036] Such as Figure 1-13 As shown, the fully automatic lens production and processing equipment includes a frame 1, on which a grinding device 2 and a swing device 3 are arranged at intervals, and the swing device 3 includes a swing mechanism 31 arranged on the frame 1 , the lifting mechanism 32 connected to the driving end of the swing mechanism 31, and the pressing mechanism located on the lifting mechanism 32, the lifting mechanism 32 is used to drive the pressing mechanism to approach or move away from the grinding device 2. The swing mechanism 31 is used to drive the lifting mechanism 32 to swing, so that the pressing mechanism swings relative to the grinding device 2; the pressing mechanism includes a connecting seat slidingly arranged on the lifting mechanism 32 33. The lens suction group 34 provided on the connecting seat 33 for sucking the lens, and the lens pressing group 35 provided between the driving end of the lifting mechanism 32 and the connecting seat 33, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com