Automatic reversing winding displacement device for rope drum of steel wire rope

A technology of automatic reversing and cable arrangement, which is applied in hoisting devices, spring mechanisms, etc., can solve problems such as shortening the service life of steel wire ropes, extrusion damage of steel wire ropes, and affecting the service life of steel wire ropes, so as to avoid extrusion damage, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

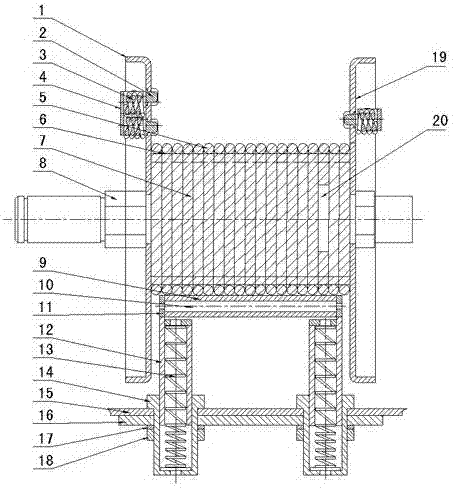

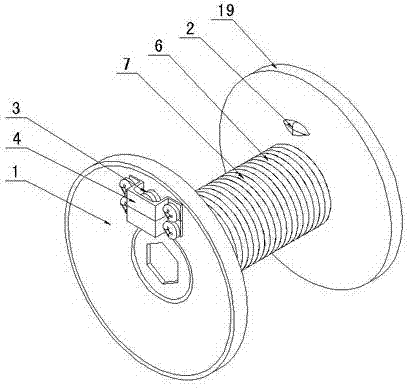

[0012] figure 1 and figure 2 As shown, the present invention creates a specific embodiment of a wire rope drum automatic reversing cable arrangement, which includes a rope drum 7 arranged on a rotating shaft 8, a wire pressing mechanism fixed on a casing 15, and the rope drum The left and right side plates 1, 19 of 7 are provided with at least one layer of wire rope routing guide mechanisms, and the wire rope routing guide mechanisms on the left and right side plates 1, 19 are arranged crosswise and arranged at the wire rope conversion winding layer. The mechanism includes a wire rope guide block 2, a thrust spring 3 and a guide seat 4. The wire rope guide block 2 is installed on the T-shaped mounting holes of the left and right side plates 1, 19. The T-shaped mounting holes ensure that the wire rope guide block 2 does not come out, and the guide seat 4 is fixed. On the left and right side plates 1, 19, the thrust spring 3 is arranged between the end of the wire rope guide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com