A cathode device for batch electroplating metal heat sink elements

A technology for electroplating metals and components, applied in the direction of electrodes, etc., can solve the problems of no use value, inability to provide high uniformity, and thin metal heat sink components, so as to stabilize the current of the electroplating process, improve the electroplating effect, and improve the The effect of ohmic contact quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

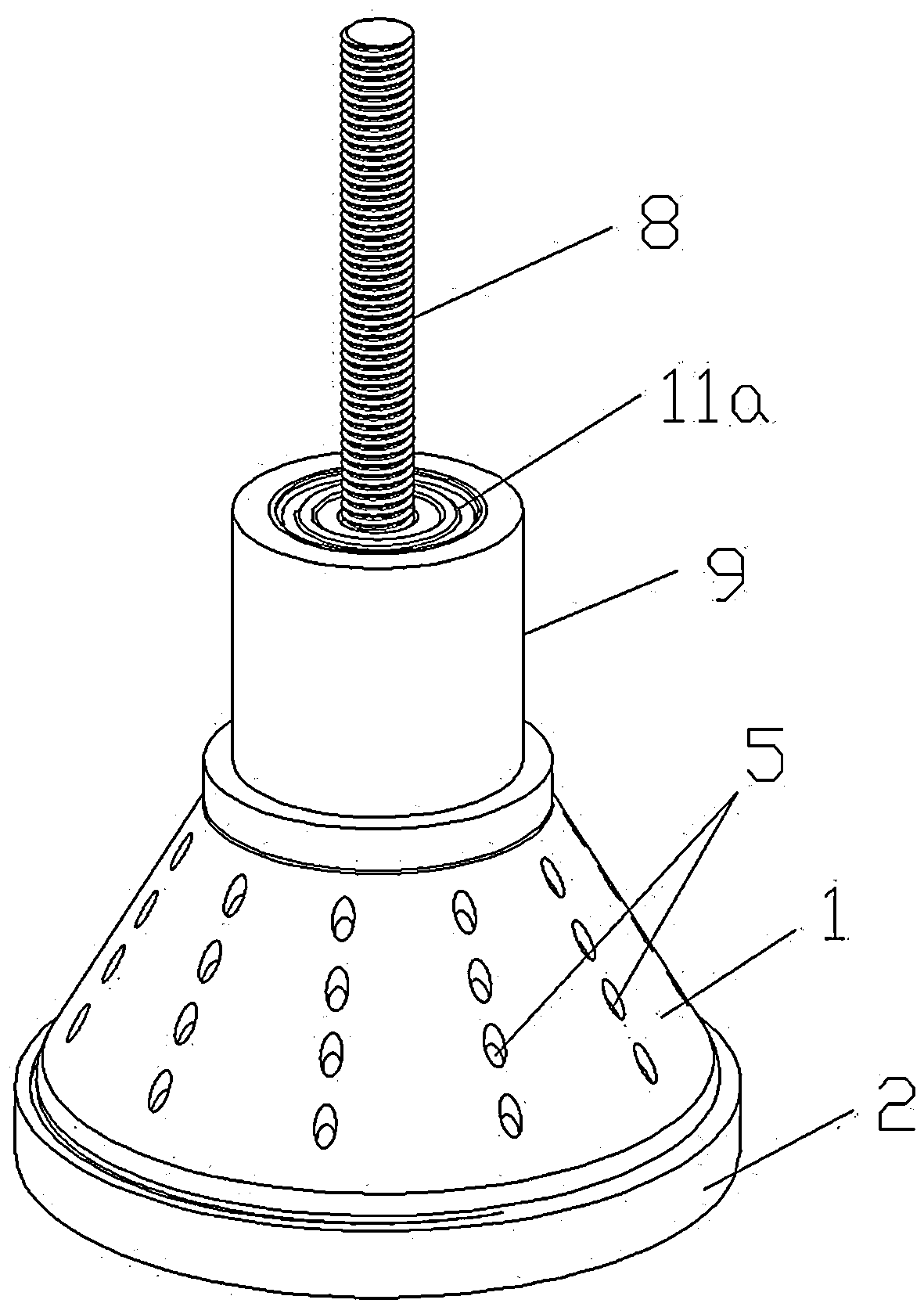

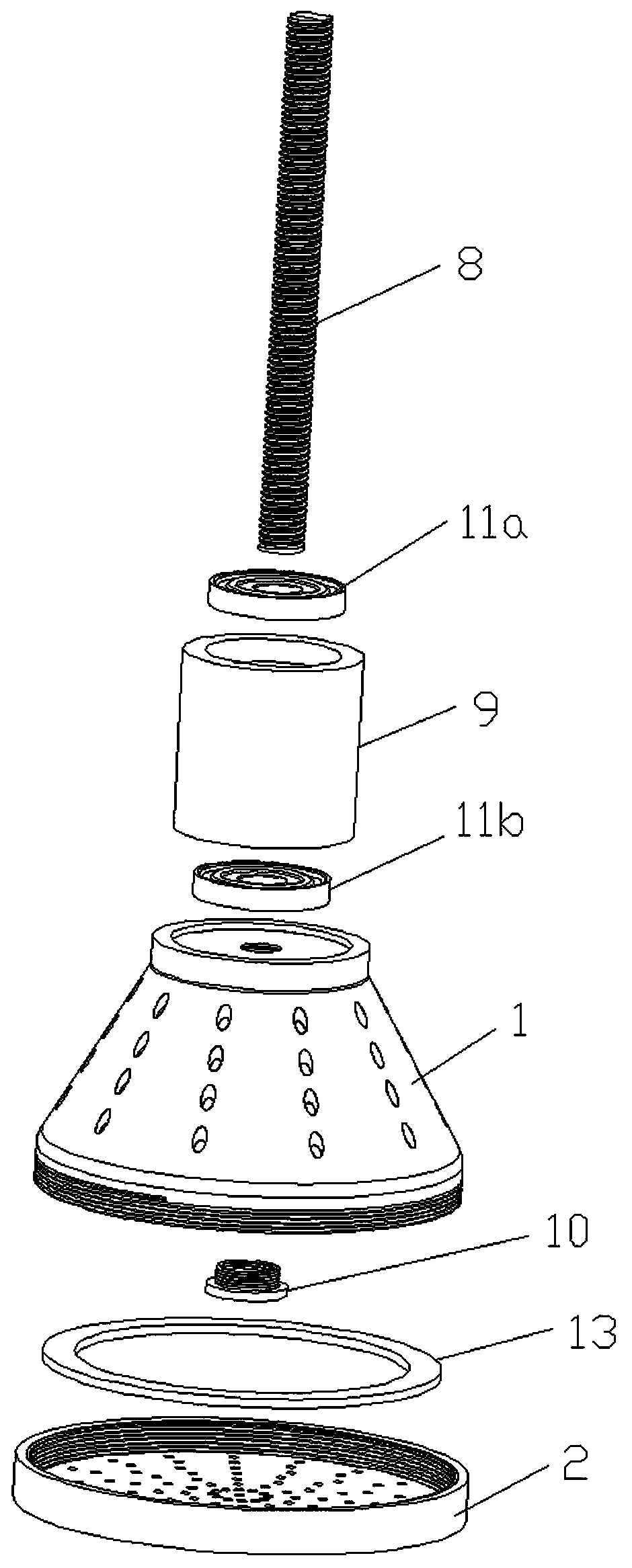

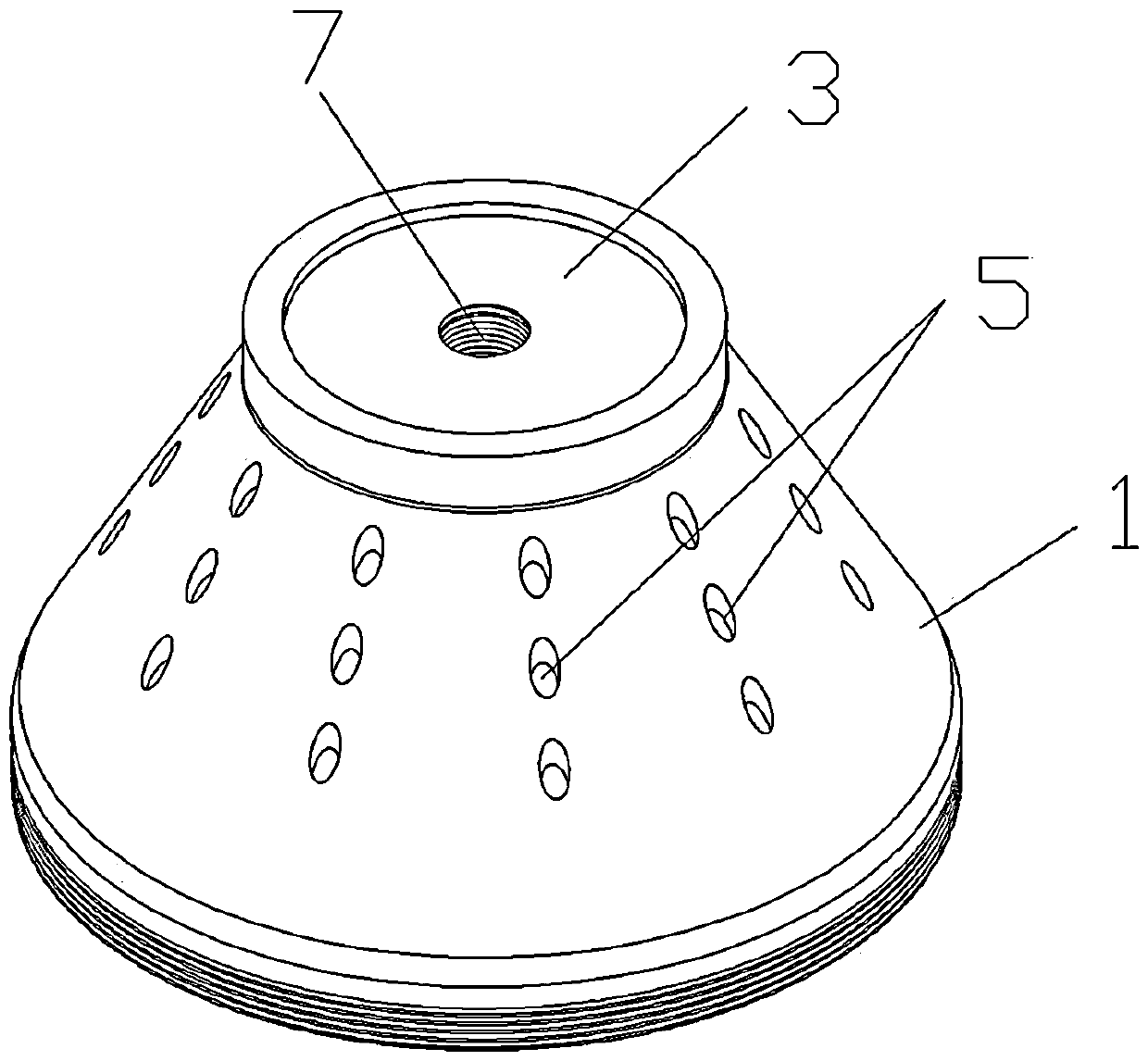

[0031] combine figure 1 and figure 2 As shown, the present invention provides a cathode device for batch electroplating metal heat sink elements, including a loading case 1 and a loading tray 2; Figure 3-5 As shown, the loading case 1 is in the shape of a truncated cone, the top surface of the loading case 1 is provided with a conductive sheet 3, and the inner side of the bottom of the loading case 1 is provided with a conductive ring 4; The hole array 5, the shell wall of the loading case 1 is also embedded with a group of metal leads 6, the top of the metal leads 6 is connected with the conductive sheet 3, and the bottom end is connected with the conductive ring 4; as preferred, the metal leads 6 Contains four, evenly distributed in the shell wall of the loading shell 1.

[0032] The center of the conductive sheet 3 is provided with a screw hole 3a, and the top of the loading case 1 is provided with a mounting hole 7 concentric with the screw hole 3a. The mounting hole 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com