Production method of double-sided thick copper flexible working board

A production method and technology for working boards, which are used in circuit lamination, electrical components, printed circuit manufacturing, etc., can solve the problems of poor electroplating uniformity, insufficient glue filling in line gap positions, and residual copper line spacing on the edge of the board, and achieve uniform electroplating. The effect of good performance, good drilling quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

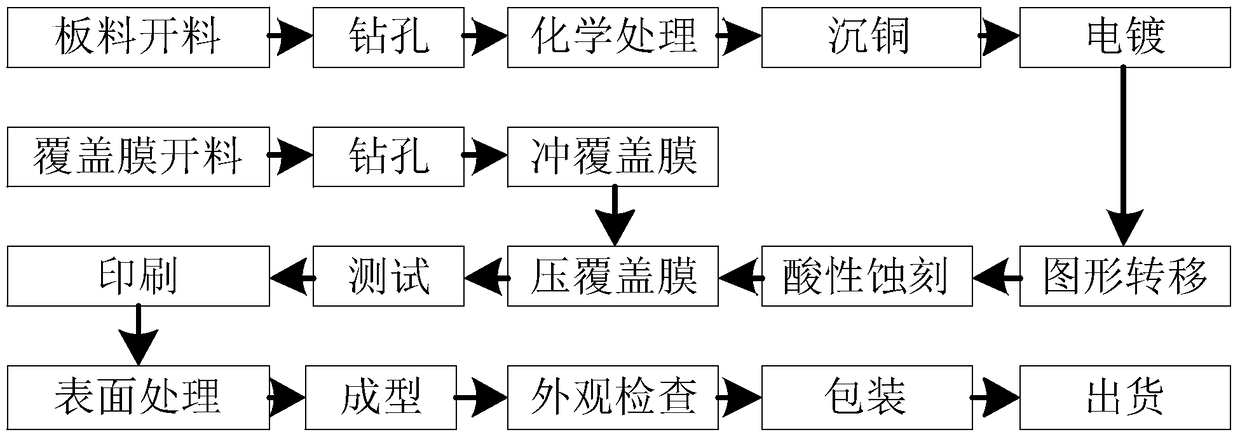

[0012] Please refer to figure 1 , the invention provides a kind of production method of double-sided thick copper flexible working plate, comprising:

[0013] Step 1, Drilling: Use a diamond-coated drill with a cutting speed of 1-2m / min, a cutting speed of 10-12m / min, a speed of 20KRPM, a cutting amount of 0.05-0.1mm / circle, and 500-1000 Hole / branch drill life, 2-4PNL / stack number of stacked boards to drill through holes on the substrate; using these parameters to produce, can effectively control the roughness in the hole and board surface burrs, burrs and other problems, to ensure that the hole The substrate is intact and undamaged. In this process, the drilling quality should be strictly controlled. The roughness in the hole is not allowed to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com