Horizontal continuous electroplating device and preparation method thereof

An electroplating device, a horizontal technology, applied in the direction of printed circuit manufacturing, electrical components, electrolysis process, etc., can solve the problems of lotus leaves and white spots on the edge of the board, and achieve the effect of increasing electrical conductivity, uniform current distribution, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

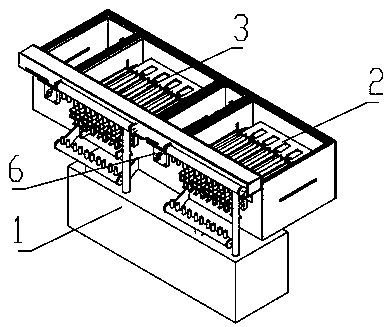

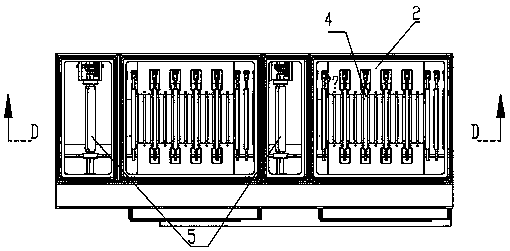

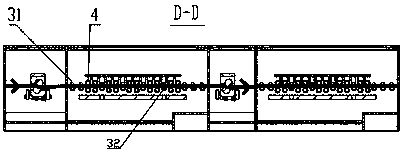

[0029] like Figure 1 to Figure 3 As shown, a horizontal continuous electroplating device comprises an electroplating tank 1 filled with a copper-plating liquid, immersed in an electroplating tank 1 filled with a copper-plating liquid and an upper and lower anode electroplating spray pipe 4 that sprays the liquid to the plated parts, and uses The horizontal conveying roller device 3 for horizontally conveying the plating plate, and the cathode copper conductive roller 5 located on the horizontal conveying frame 6 and placed on the plating plate up and down, the anodic electroplating spray pipe 4 is a tubular type made of titanium structure, the anodic plating spray pipe 4 is coated with an iridium oxide coating on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com