Anode shielding used for increasing electroplating uniformity

A uniformity and anode technology, which is applied in the field of anode screen to improve the uniformity of electroplating, can solve the problems of unusable PCB boards, increased processes, waste, etc., and achieve the effects of uniform thickness, improved electroplating uniformity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

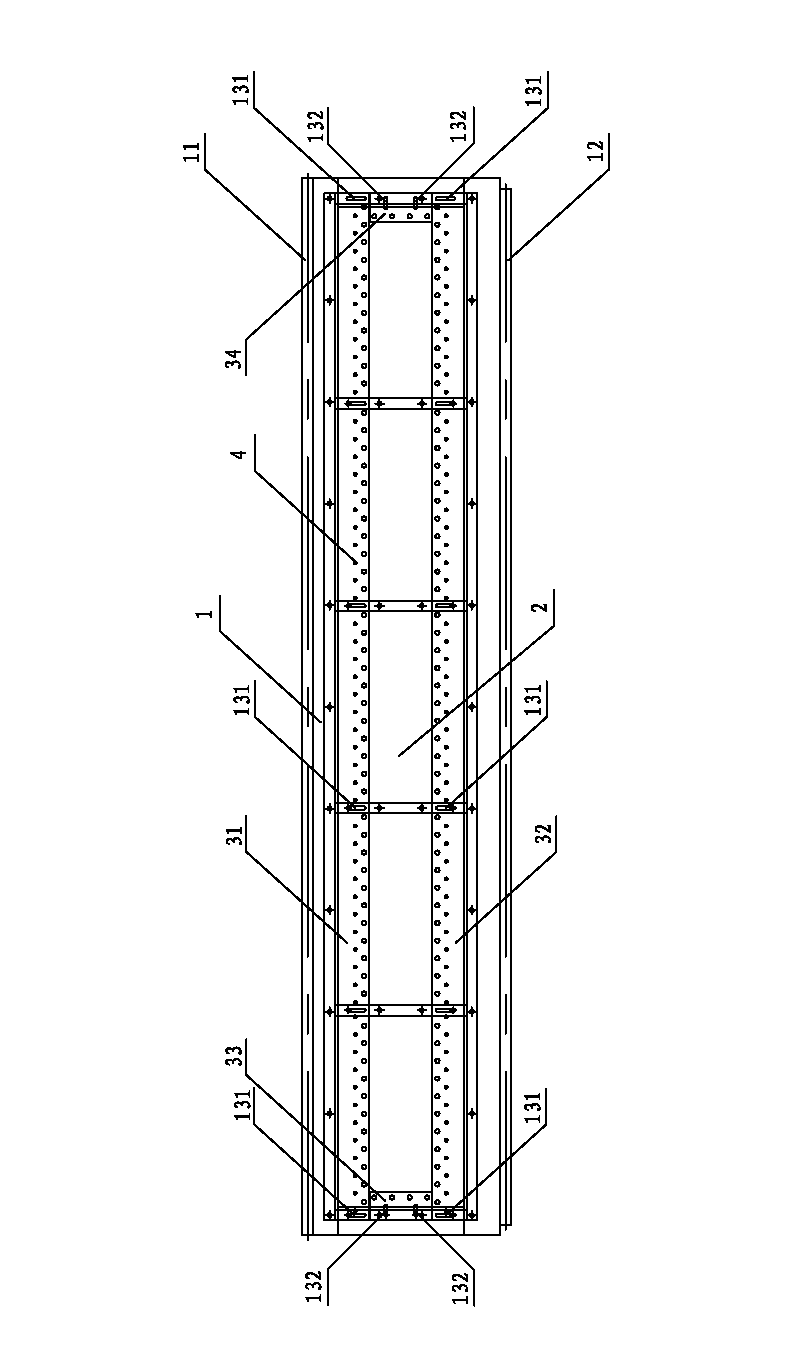

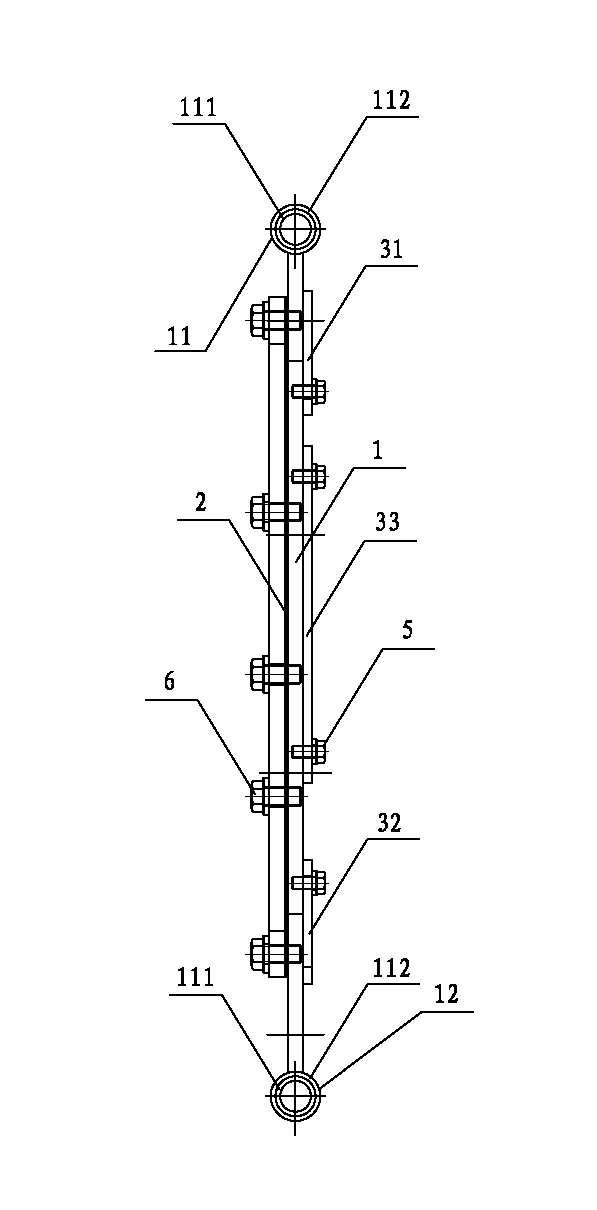

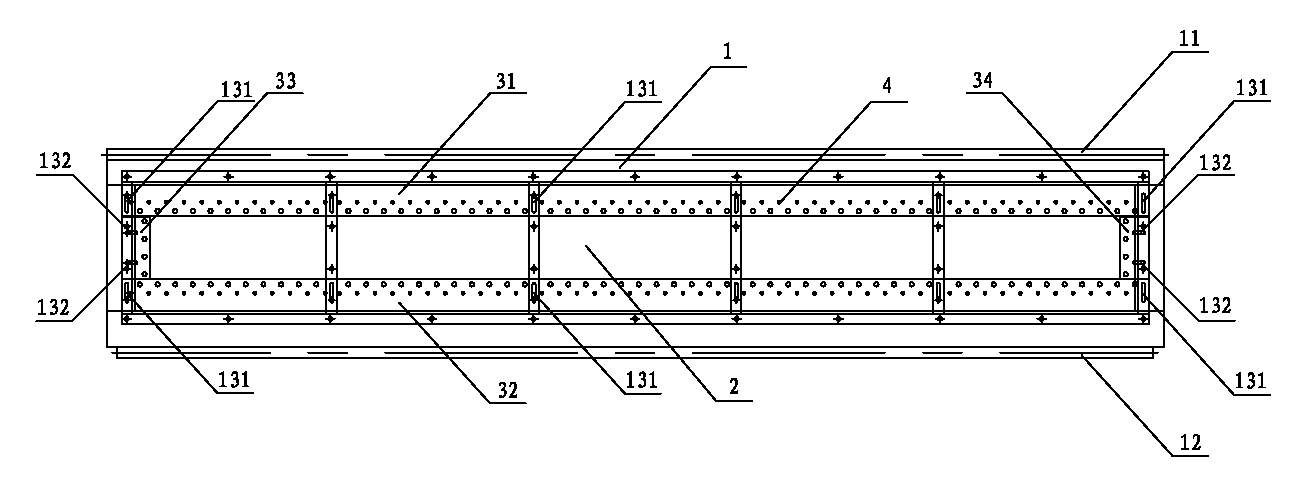

[0030] Such as figure 1 and figure 2 As shown, an anode screen for improving the uniformity of electroplating includes an anode screen frame 1 and an anode screen cloth 2 detachably fixed on the anode screen frame 1, and the anode screen cloth 2 connects the anode screen frame 1 The inner frame is completely covered; it also includes four flat plates with through holes 4, and the flat plates are respectively fixed on the four edges of the anode screen cloth 2, which are the upper, lower, and upper adjustment plates 31, 32, Anode screen left adjustment plate 33, anode screen right adjustment plate 34.

[0031] Wherein, the anode screen cloth 2 is detachably fixed on the anode screen frame 1 by the second polypropylene hexagonal screw 6 . The anode screen cloth 2 is preferably polypropylene material. The specification of the second polypropylene hexagon screw 6 is M12×25.

[0032] Wherein, the upper adjustment plate 31 of the anode screen and the lower adjustment plate 32 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com