Chemical nickel plating process for bearing steel

A technology of electroless nickel plating and bearing steel, which is applied in the direction of liquid chemical plating, metal material coating technology, coating, etc., can solve the problems of complex composition of plating solution, cumbersome preparation of plating solution, slow deposition speed, etc. Good effect, simple raw material composition and preparation process, fast deposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

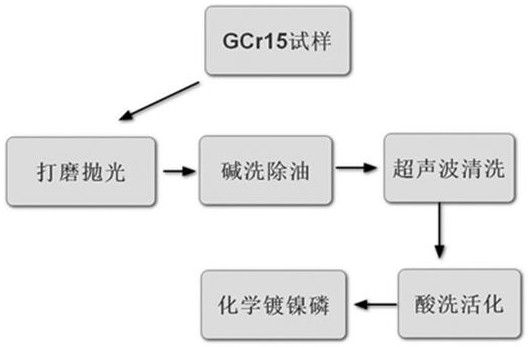

[0027] see figure 1 , an electroless nickel plating process for bearing steel, which is specifically carried out according to the following steps:

[0028] S1, grinding and polishing

[0029] The surface of the bearing steel sample is first polished with 180-mesh, 320-mesh, 600-mesh, and 1000-mesh sandpaper once, then rough polished with 2.5μm diamond polishing liquid, and then finely polished with 0.5μm diamond polishing liquid to the mirror surface. Clean and dry with deionized water at room temperature. The sandpaper should be polished in the same direction until the sanding surface is covered with wear marks. When replacing the sandpaper, the bearing steel sample should be rotated 90° to ensure that the next grinding direction is the same as the previous one. vertical direction;

[0030] S2, alkaline degreasing

[0031] First immerse the polished bearing steel in an alkaline degreasing solution with a temperature of 70°C for 10 minutes, and then wash the bearing steel w...

Embodiment 2

[0039] The difference from Example 1 is:

[0040] In step S2, the raw material composition and content of the alkaline degreasing solution are 23 g / L of sodium hydroxide, 25 g / L of anhydrous sodium carbonate, 30 g / L of sodium phosphate, and 10 g / L of sodium silicate;

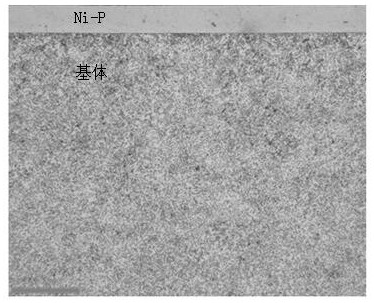

[0041] In step S5, the raw material composition and content of the electroless nickel plating solution are nickel sulfate 25g / L, sodium hypophosphite 25g / L, lactic acid 20ml / L, citric acid 8g / L, sodium acetate 20g / L, thiourea 2mg / L, the pH of the electroless nickel plating solution was 5.2, the temperature was 85° C., and the thickness of the obtained plating layer was 20 μm.

Embodiment 3

[0043] The difference from Example 1 is:

[0044] In step S2, the raw material composition and content of the alkaline degreasing solution are sodium hydroxide 25g / L, anhydrous sodium carbonate 30g / L, sodium phosphate 50g / L, and sodium silicate 20g / L;

[0045] In step S5, the raw material composition and content of the electroless nickel plating solution are nickel sulfate 30g / L, sodium hypophosphite 30g / L, lactic acid 30ml / L, citric acid 10g / L, sodium acetate 30g / L, thiourea 3mg / L, the pH of the electroless nickel plating solution was 6, the temperature was 90° C., and the thickness of the obtained plating layer was 30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com