Adsorption device and method of metal pattern plates, evaporation equipment and evaporation method

An adsorption device and mask technology, applied in vacuum evaporation plating, sputtering plating, gaseous chemical plating, etc., can solve the problems of FMM wrinkles, improve quality, enhance anti-deformation performance, and avoid unnecessary waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

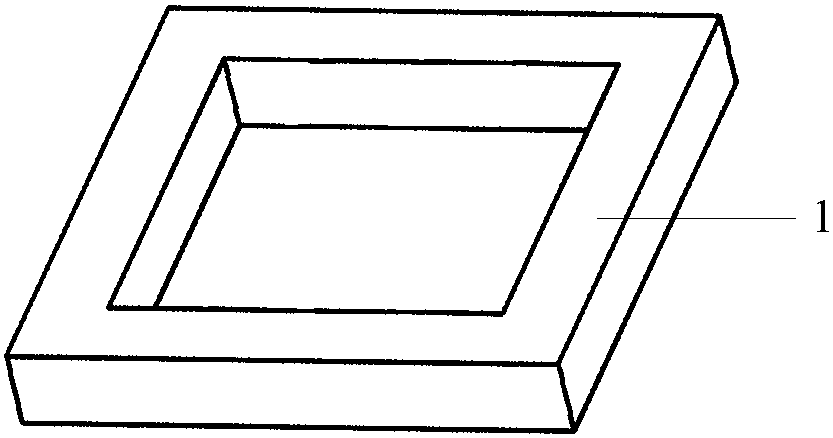

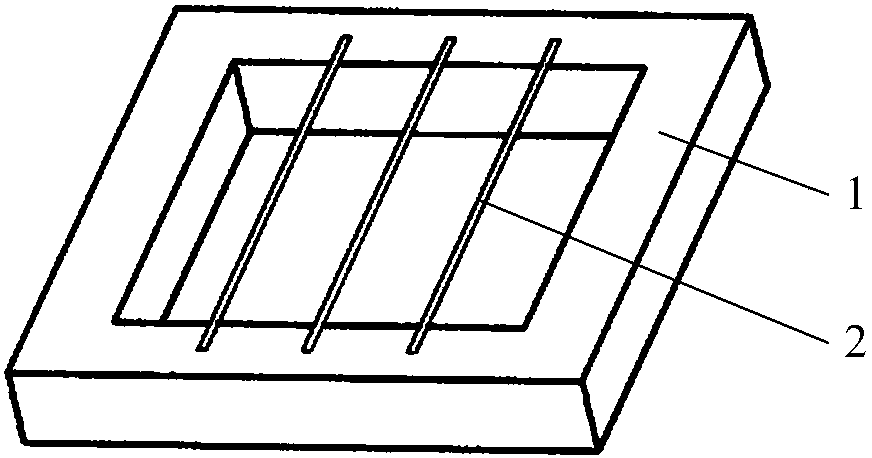

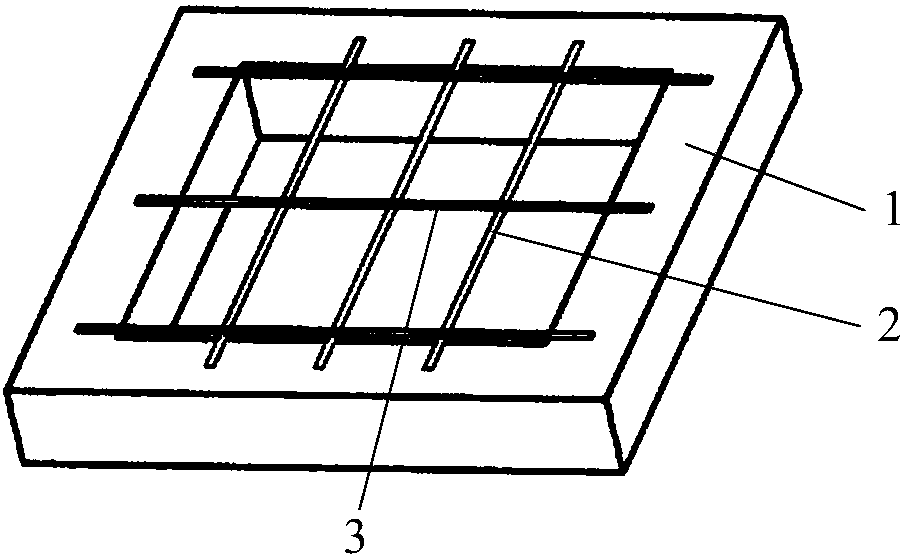

[0062] This embodiment provides a mask adsorption device, such as Figure 5a ~ Figure 5d As shown, the adsorption component of the adsorption device includes: a first carrier board 11 , at least two electromagnets dispersedly arranged on the first carrier board, and at least two switches.

[0063] Wherein, the first carrier plate 11 is used to carry the electromagnet, and the first carrier plate 11 is a rigid flat plate.

[0064] The electromagnet can be embedded on the first carrier board 11 , or directly installed on the first carrier board 11 . The electromagnet can generate magnetic force when it is turned on, and at least two electromagnets included in the adsorption component can generate the same magnetic force at the same time, so that when the entire mask is adsorbed, a relatively uniform adsorption force can be generated on each area of the mask . Such as Figure 3a As shown, the structure of the electromagnet 7 is: comprising an iron core 71, and several turns ...

example 1

[0075] Example 1: If Figure 6a ~ Figure 6c As shown, if the initial adsorption area is the central area of the mask, the adsorption method includes: turn on the electromagnet corresponding to the initial adsorption area, and then turn on the corresponding electromagnet in turn from the initial adsorption area in a radial manner until The whole mask is adsorbed and adhered to the base substrate 5 , at this time, each electromagnet generates the same magnetic force, and exerts a uniform adsorption force on each area of the whole mask. This adsorption method can be matched with Figure 4b The arrangement of the electromagnet shown in the adsorption part makes the magnetic force control of the adsorption part more precise.

example 2

[0076] Example 2: If Figure 7a ~ Figure 7c As shown, if the initial adsorption area is the central area of each FMM of the mask, the adsorption method is similar to Example 1, and will not be repeated here.

[0077] It should be noted that the "central region" mentioned in this embodiment and the following embodiments 2 and 3 refers to the center point and the surrounding area, not limited to a circular area, but also a rectangular area, or other shapes area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com