Frame automatic film pasting device and film pasting method thereof

A film sticking device and frame technology, applied in packaging and other directions, can solve the problems of unable to stick film on products with corners, large manpower demand, complex structure, etc., and achieve the effect of simple structure, good applicability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

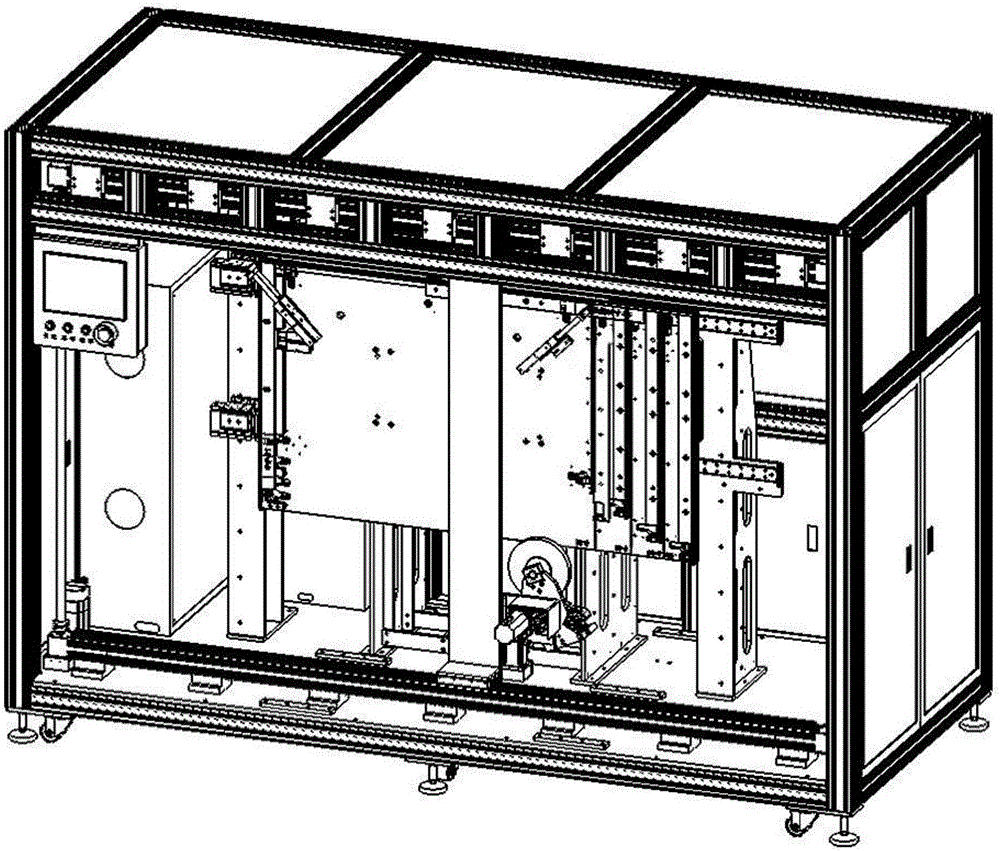

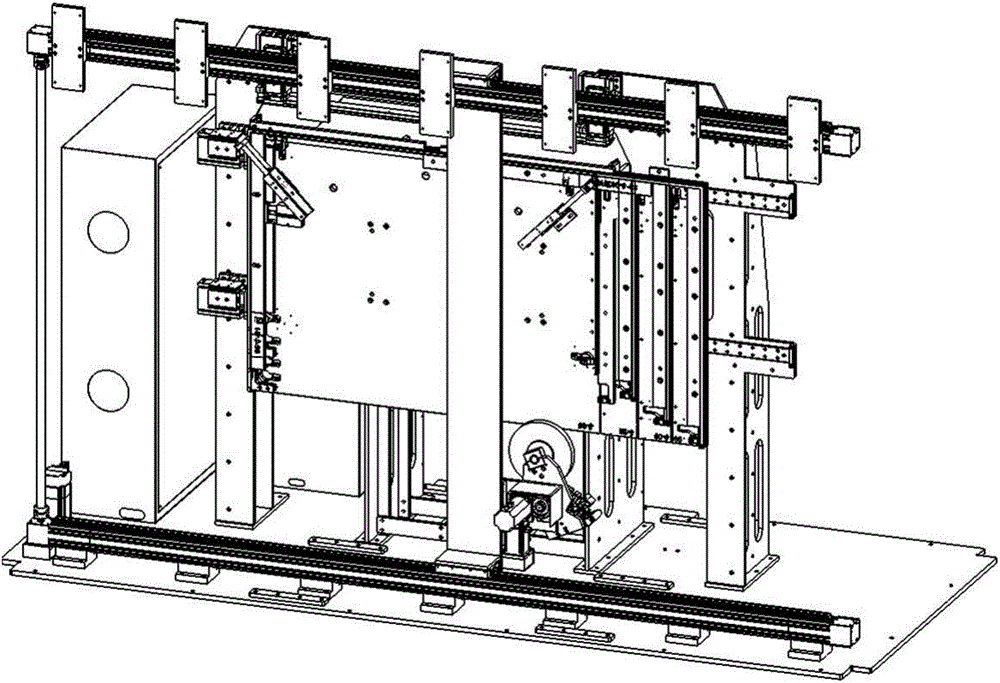

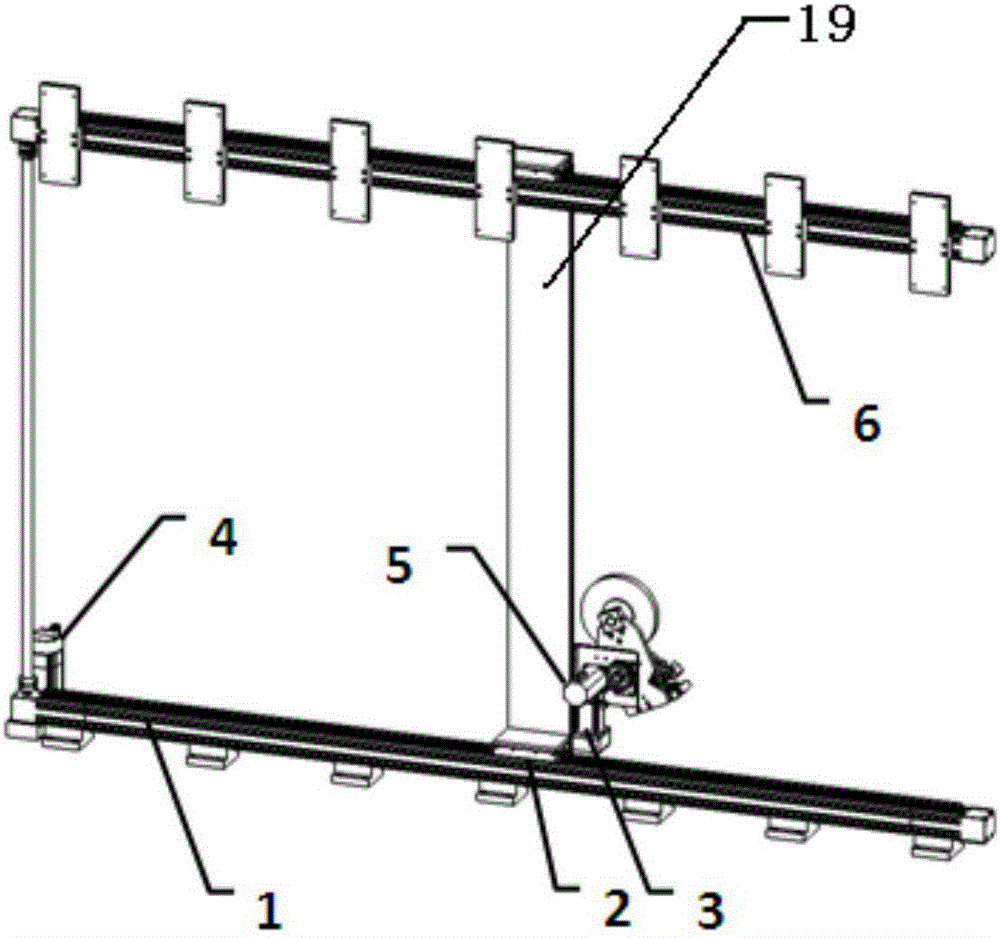

[0061] Such as Figure 1-2 As shown, a frame automatic film sticking device includes a frame automatic positioning device, a film sticking mechanism and an automatic film covering mechanism; the frame automatic positioning device fixes the frame to be filmed on the jig plate; the film sticking mechanism is used to place the protective film Paste on the outer walls around the frame to be filmed, and the film sticking mechanism includes a first horizontal linear module 1, a second horizontal linear module 6, a vertical linear module 19, a film assembly, a first motor 4, and a second motor 3 and the third motor 5; the first horizontal linear module 1 is parallel to the second horizontal linear module 6, and the second horizontal linear module 6 is located above the first horizontal linear module 1; the vertical linear module The two ends of 19 are respectively connected with the first horizontal linear module 1 and the second horizontal linear module 6; the first motor 4 is arran...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is:

[0073] Such as Figure 12-17 As shown, the laminating mechanism includes a laminating frame and a displacement assembly, and the laminating frame is provided with an upper laminating cylinder 203, a left laminating cylinder 201, and a right laminating cylinder 204; the upper laminating cylinder 203 , the left laminating cylinder 201 and the right laminating cylinder 204 are respectively provided with a first flattening part 216, a second flattening part 202 and a third flattening part 217; The bit assembly includes: a fourth motor 209, a gear 211, a rack 212, a jig connecting plate 207, and a first connecting plate 214. The output shaft of the fourth motor 209 is connected to the gear 211, and the gear 211 meshes with the rack 212. The two ends of the fixture connection plate 207 are connected with a fixture fixing plate 208, and the fixture connection plate 207 is also connected with the rack 212; the first...

Embodiment 3

[0081] The difference between this embodiment and embodiment one and embodiment two is:

[0082] Such as Figure 18-22 As shown, the frame automatic positioning device includes a fixture plate 107, a left positioning cylinder 104, an upper positioning cylinder 108, a right positioning cylinder, a left corner cylinder 102, an upper corner cylinder 106, a right corner cylinder 109 and an inner top cylinder 103; the left positioning cylinder 104, the upper positioning cylinder 108, and the right positioning cylinder are respectively arranged on the left outer side, the upper outer side, and the right outer side of the fixture plate 107, and the left positioning cylinder 104, the upper positioning cylinder 108, and the piston on the right positioning cylinder The direction of motion of the rod is all perpendicular to the corresponding sidewall on the fixture plate 107; the left corner cylinder 102, the upper corner cylinder 106, and the right corner cylinder 109 are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com