Gap adjustment frame between instrument panel and central large screen

A gap adjustment, instrument panel technology, applied in the upper structure sub-assembly, vehicle parts, transportation and packaging, etc., can solve the problems of insufficient gap, unsightly, abnormal noise, etc., to solve the problem of excessive gap or insufficient gap, eliminate Inaccurate positioning, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

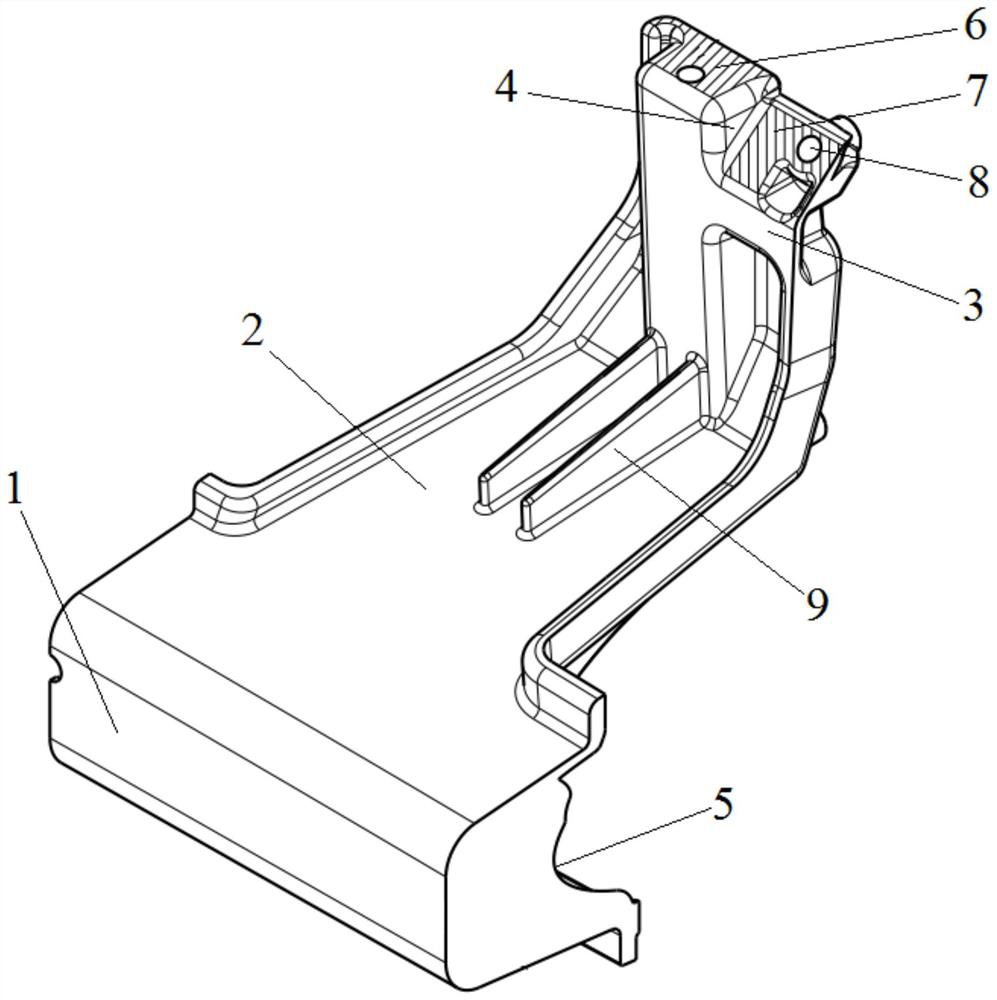

[0023] combine figure 1 As shown, a gap adjustment frame between an instrument panel and a central large screen disclosed in an embodiment of the present invention includes a beam connecting portion 1 , a frame body 2 , an installation branch 3 and a spacer plate 4 . The beam connection part 1, the frame body 2, the spacer plate 4 and the installation branch part 3 are integrally cast. Wherein, the crossbeam connection part 1 is elongated and can be arranged along the instrument panel crossbeam, and the crossbeam connection part 1 has an abutment surface 5 for abutting against the instrument panel crossbeam, and the abutment surface 5 is a curved surface, which can fit the instrument panel Board beams. One end of the frame body 2 is fixedly connected to the upper part of the beam connecting portion 1, and the other end of the frame body 2 forms a central large screen installation plane 6, and the central large screen can be fixed on the central large screen installation plane...

Embodiment 2

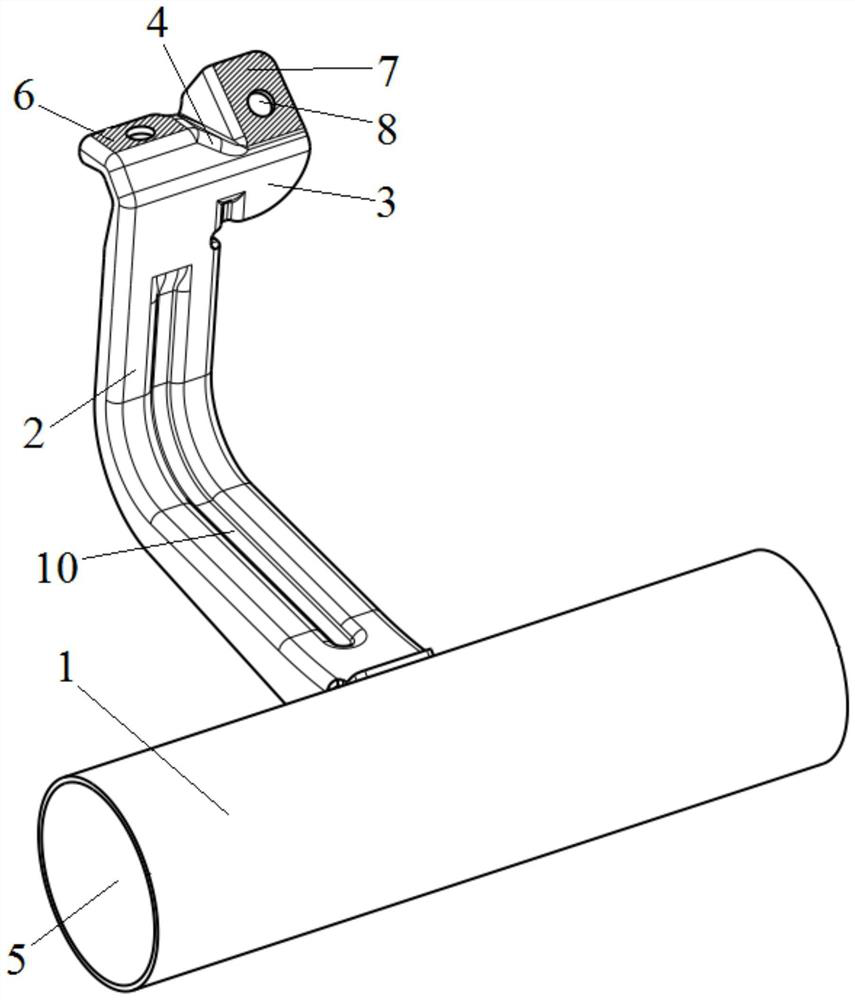

[0028] combine figure 2 As shown, as yet another embodiment of the present invention, the difference from the previous embodiment is that the beam connection part 1, the frame body 2, the spacer plate 4 and the installation branch part 3 of this embodiment are all sheet metal parts. Specifically, the beam connecting portion 1 is cylindrical, and the inner peripheral surface of the beam connecting portion 1 is a contact surface 5 .

[0029] Further, the frame body 2 includes a connecting section and a supporting section, the two ends of the connecting section are respectively connected to the beam connecting part 1 and the supporting section, and the connection between the supporting section and the connecting section is rounded, and the middle part of the supporting section and the connecting section forms a There are ribs 10, and the bearing capacity of the frame body 2 is enhanced by adding ribs 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com