Automatic frame locating device and method

A technology of automatic positioning and positioning method, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of reducing production capacity, unable to provide help for border operation, and fast positioning action, so as to overcome inaccurate positioning and ensure accurate positioning. performance and efficiency, and the effect of reducing structural complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

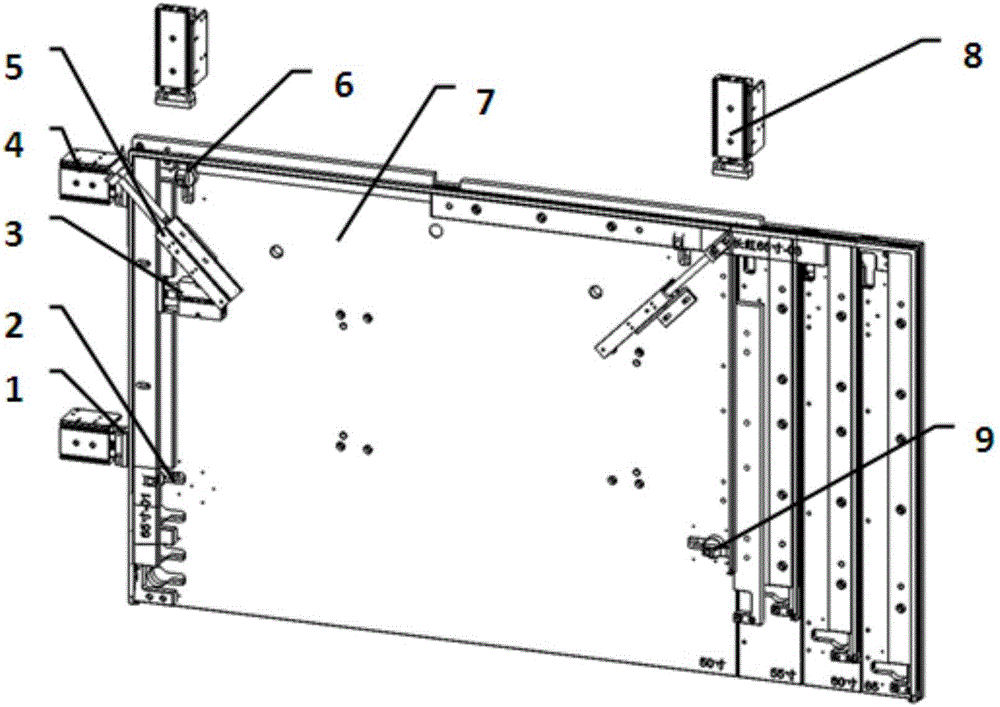

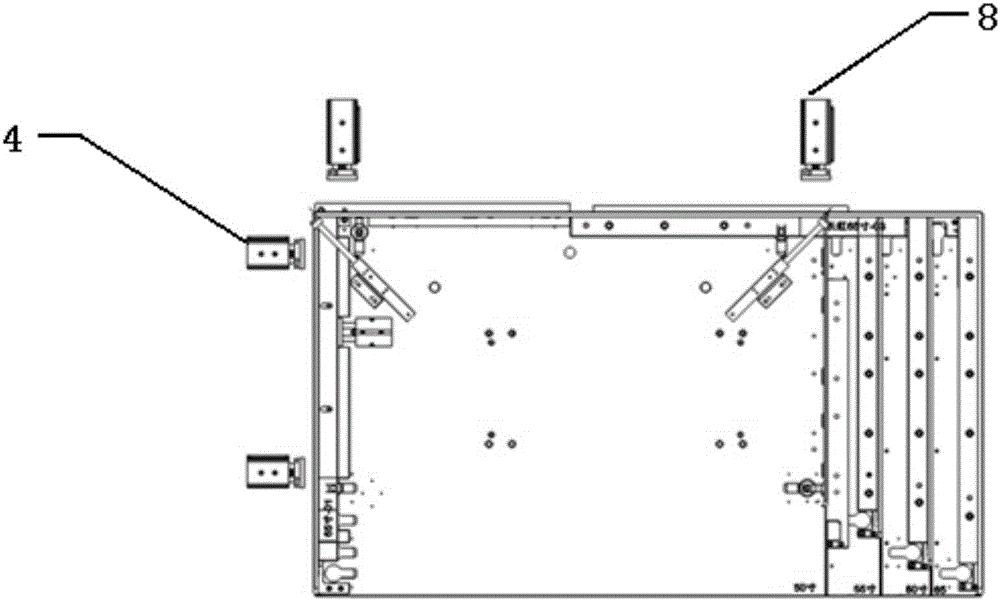

[0037] Such as Figure 1-5 As shown, a frame automatic positioning device includes a fixture plate 7, a left positioning cylinder 4, an upper positioning cylinder 8, a right positioning cylinder, a left corner cylinder 2, an upper corner cylinder 6, a right corner cylinder 9 and an inner top cylinder 3. The left positioning cylinder 4, the upper positioning cylinder 8, and the right positioning cylinder are respectively arranged on the left outer side, the upper outer side, and the right outer side of the jig plate 7, and the left positioning cylinder 4, the upper positioning cylinder 8, and the piston on the right positioning cylinder The direction of movement of the rods is all perpendicular to the corresponding side wall on the fixture plate 7; the left corner cylinder 2, the upper corner cylinder 6, and the right corner cylinder 9 are respectively arranged on the left inner side, the upper inner side and the right side of the fixture plate 7. Inner side, left corner cylind...

Embodiment 2

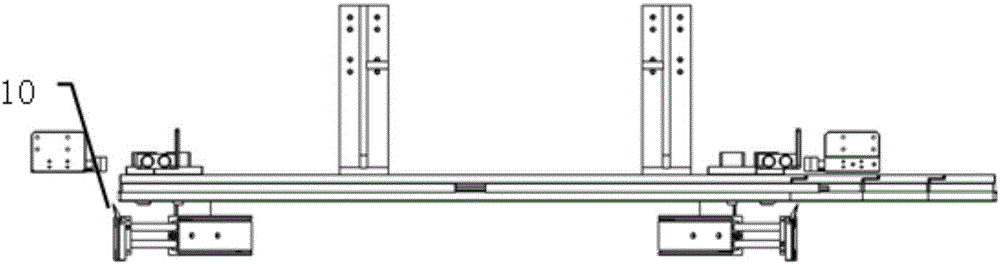

[0047] The difference between this embodiment and Embodiment 1 is that the frame automatic positioning device also includes a cutting part, and the cutting part includes a corner cutting cylinder 5 and a corner cutting knife 10 arranged on the piston rod of the corner cutting cylinder 5, and the corner cutting The cylinder 5 drives the corner cutting knife 10 to move towards the corner of the frame;

[0048]When the device of the present invention is used in a frame laminating machine, the corner cutting cylinder can be used to cut the film attached to the corner of the frame, so that when the frame is coated, no wrinkles will appear at the corner of the frame, greatly The application performance of the device of the present invention is improved.

Embodiment 3

[0050] A positioning method for an automatic frame positioning device, characterized in that it comprises the following steps:

[0051] Step 1. Put the frame to be positioned on the fixture plate 7;

[0052] Step 2, use the upper positioning cylinder 8 to withstand the upper outer side wall of the frame, and simultaneously use the left positioning cylinder 4 or the right positioning cylinder to withstand the left outer side wall or the right outer side wall of the frame;

[0053] Step 3, use the swing arm of the upper corner cylinder 6 to offset against the upper inner wall of the frame, and simultaneously use the swing arm of the left corner cylinder 2 or right corner cylinder 9 to offset the left inner wall or the right inner wall of the frame;

[0054] Step 4, use the inner top cylinder 3 to withstand the right inner wall or the left inner wall of the frame from the inside to the outside;

[0055] Step 5, use the right positioning cylinder or the left positioning cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com