A calculation method of high temperature cut-off butterfly valve for catalytic flue gas and its sealing surface

A calculation method and sealing ring technology, which is applied in the calculation field of the high-temperature cut-off butterfly valve for catalytic flue gas and its sealing ring sealing surface, can solve the problems that the valve cannot be opened, cannot meet the operation requirements, and the cut-off butterfly valve cannot apply the operation requirements, etc., to achieve Guarantee the reliability of the seal and the reliability of the action, avoid the medium particles from jamming the bearing, and maintain the effect of the flexibility of the sealing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited to the following:

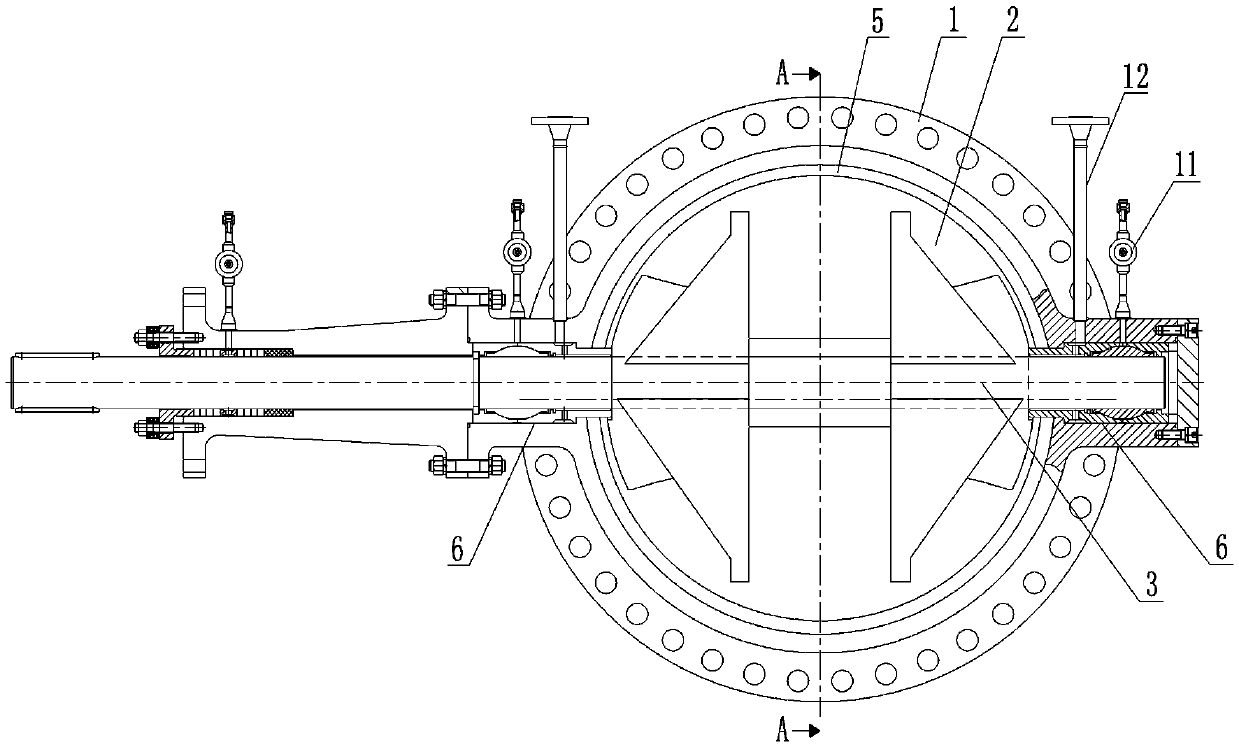

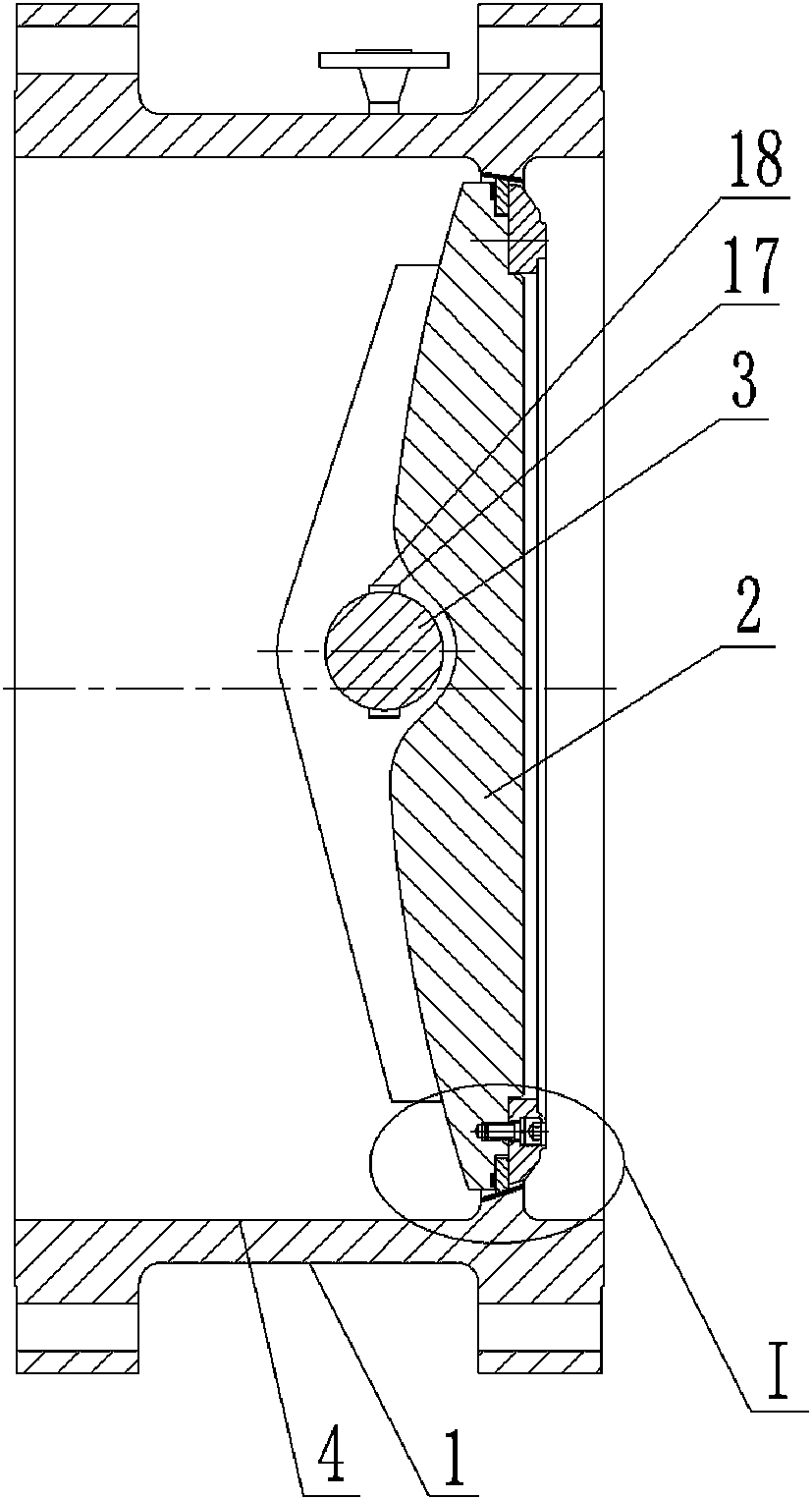

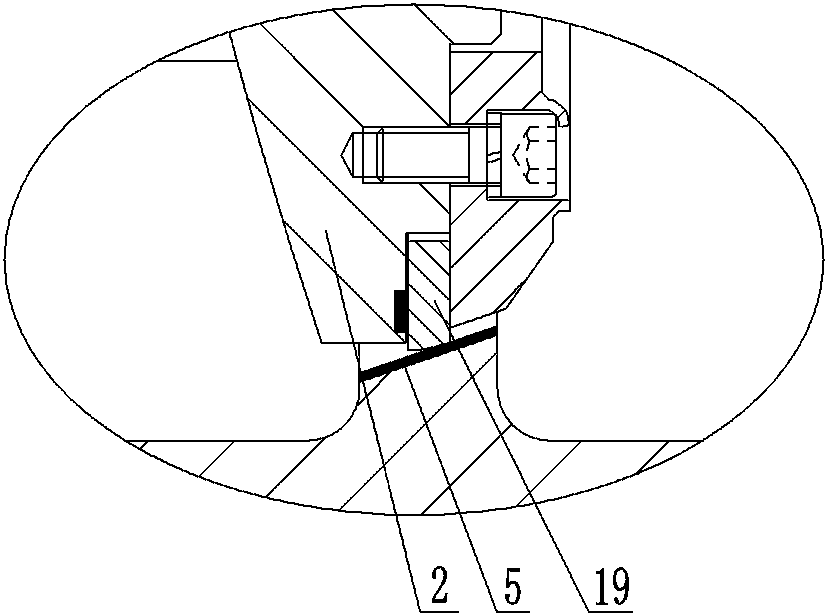

[0040] Such as Figure 1~4 As shown, a high-temperature cut-off butterfly valve for catalyzed flue gas includes a valve body 1, a valve plate 2 and a valve shaft 3. The valve body 1 is provided with a medium flow channel 4, and the medium flow channel 4 is provided with a cone The valve seat 5 is provided with stepped holes 6 on the valve body 1 and located on the left and right sides of the medium flow channel 4. The stepped holes 6 are provided with a shaft support structure, the two shaft support structures are symmetrically arranged, and the shaft support structure includes a bearing The inner ring 7, the bearing outer ring 8, the positioning ring 10, the lubricating ester adding device 11 and the purging device 12. The positioning ring 10 is fixed in the small hole of the step hole 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com