Coil-tapping machine

A tape wrapping machine and coil technology, applied in the direction of laying solid insulation, etc., can solve the problems of low work efficiency, complex structure, low degree of automation, etc., and achieve the effects of saving manufacturing costs, broad market prospects, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

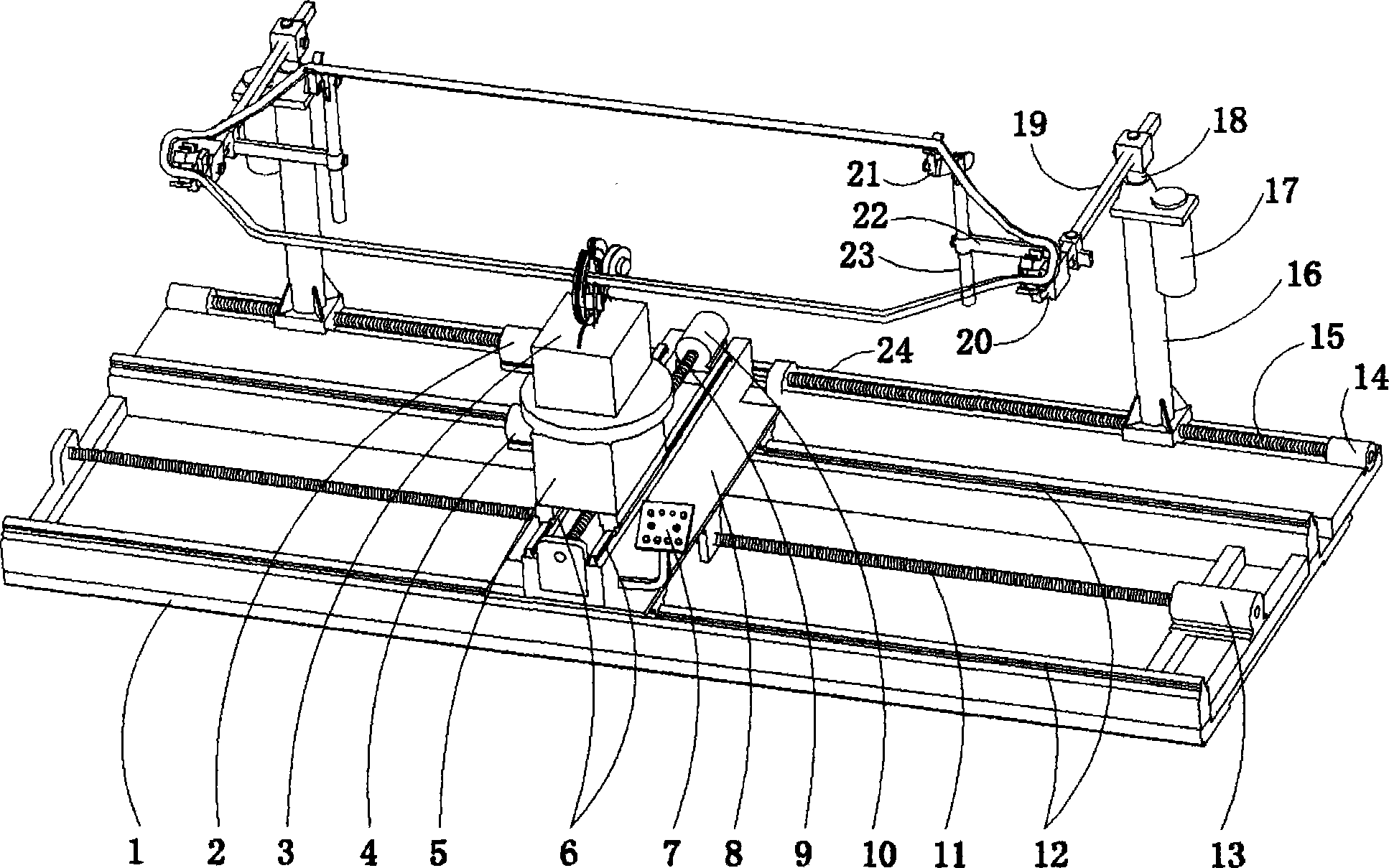

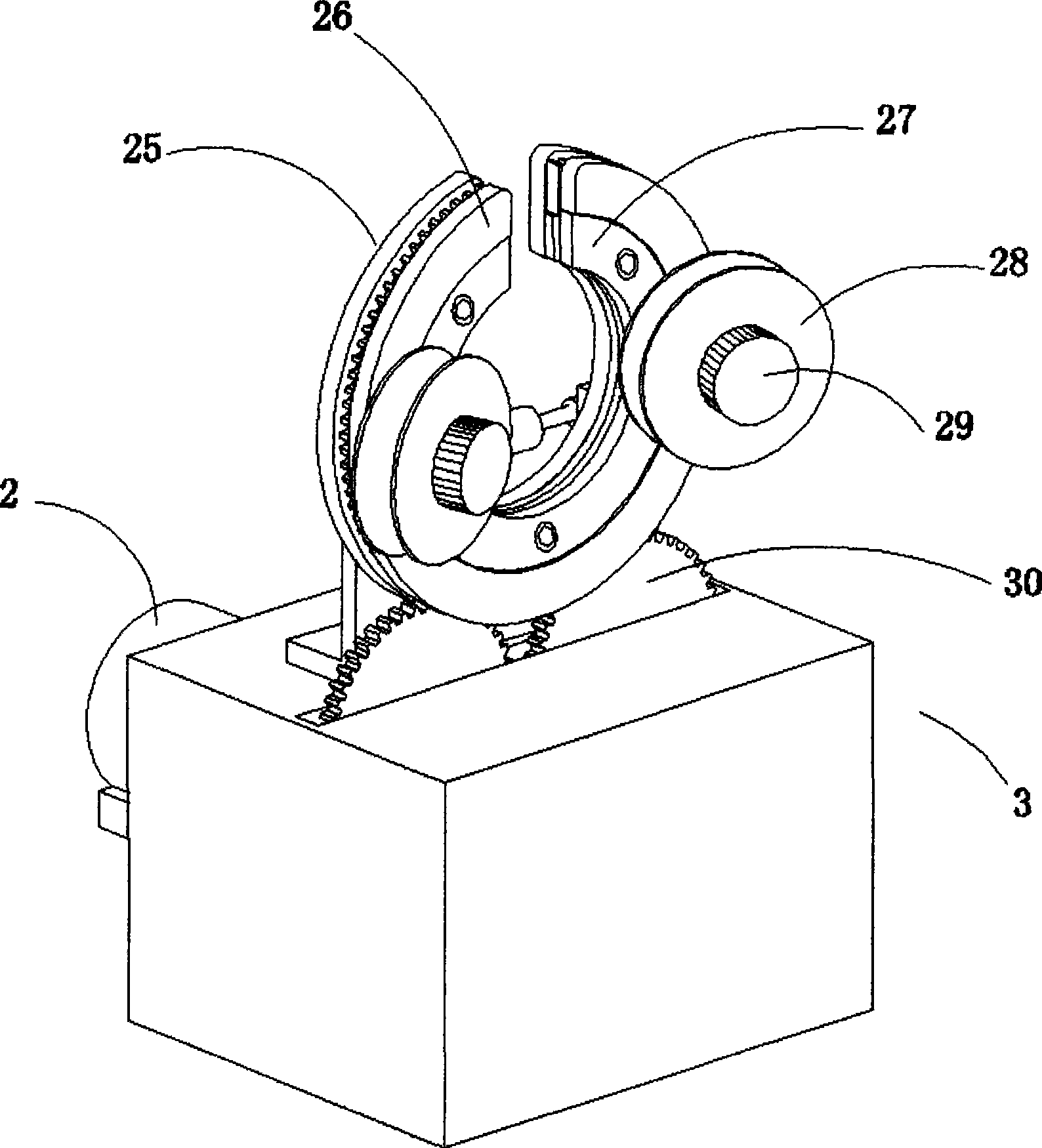

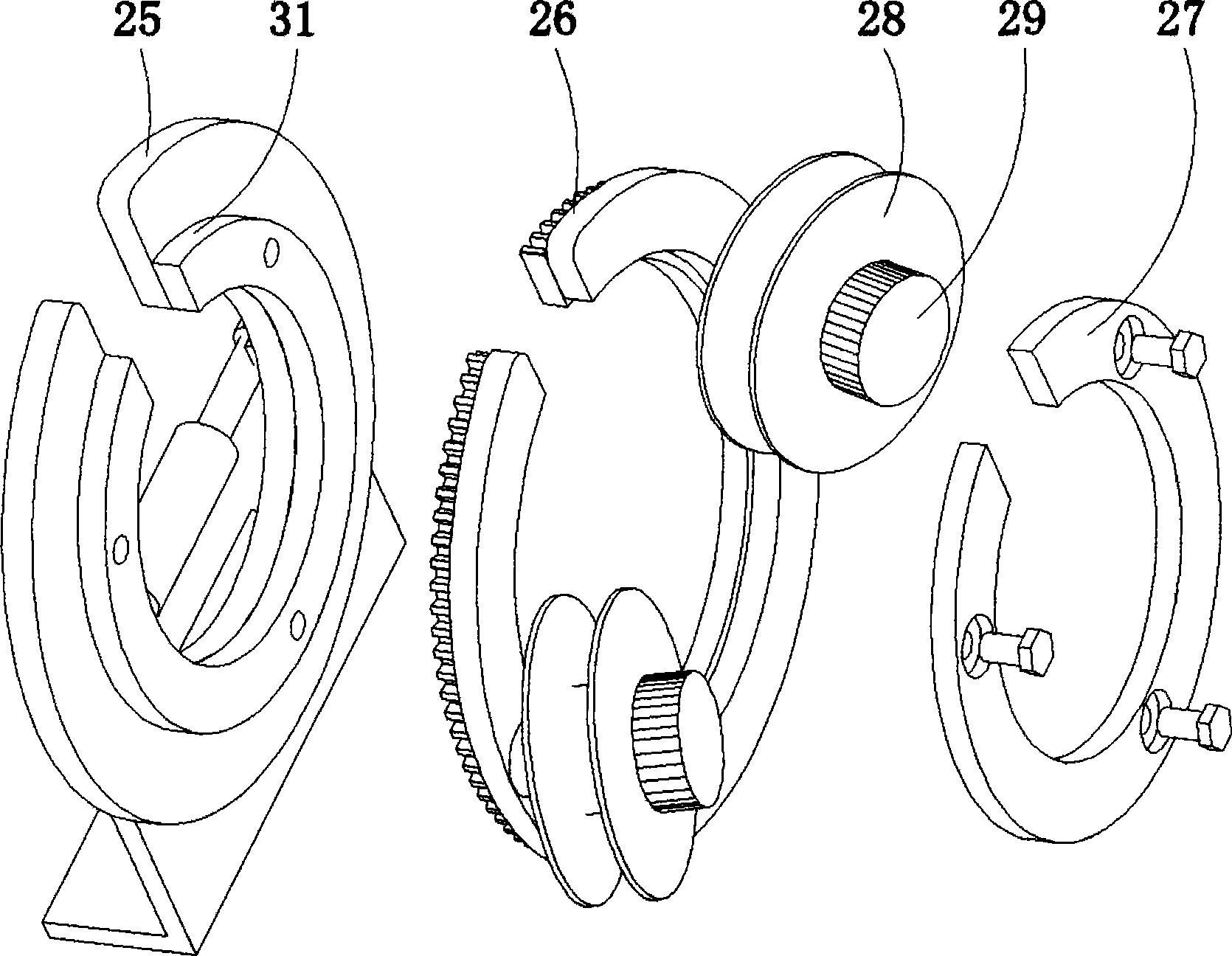

[0017] Such as figure 1 , 2 As shown in, 3 and 4, the coil wrapping machine includes a base 1, a coil fixing device, a working platform 5 and a machine head 3. On the base 1, there are a horizontal rail 12, a horizontal servo motor 13, and a threaded rod 11. On the horizontal rail 12, there is a platform base 8 that can slide along the horizontal rail 12. The horizontal servo motor 13 drives the platform base 8 along the horizontal rail 12 through the threaded rod 11 The lateral rail 12 slides left and right. On the platform base 8, there are a longitudinal track 6, a longitudinal servo motor 10 and a threaded rod 9. On the longitudinal track 6, there is a work platform 5 that can slide along the longitudinal track 6. The longitudinal servo motor 10 drives the work platform 5 along the longitudinal track 6 through the threaded rod 9 The longitudinal rail 6 slides back and forth. The working platform 5 is a rotating working platform 5 installed with a rotating servo motor 4. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com