Laminate porous film manufacturing method

A manufacturing method and porous membrane technology, applied in chemical instruments and methods, coatings, layered products, etc., can solve problems such as wrinkles and achieve continuous and stable coating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

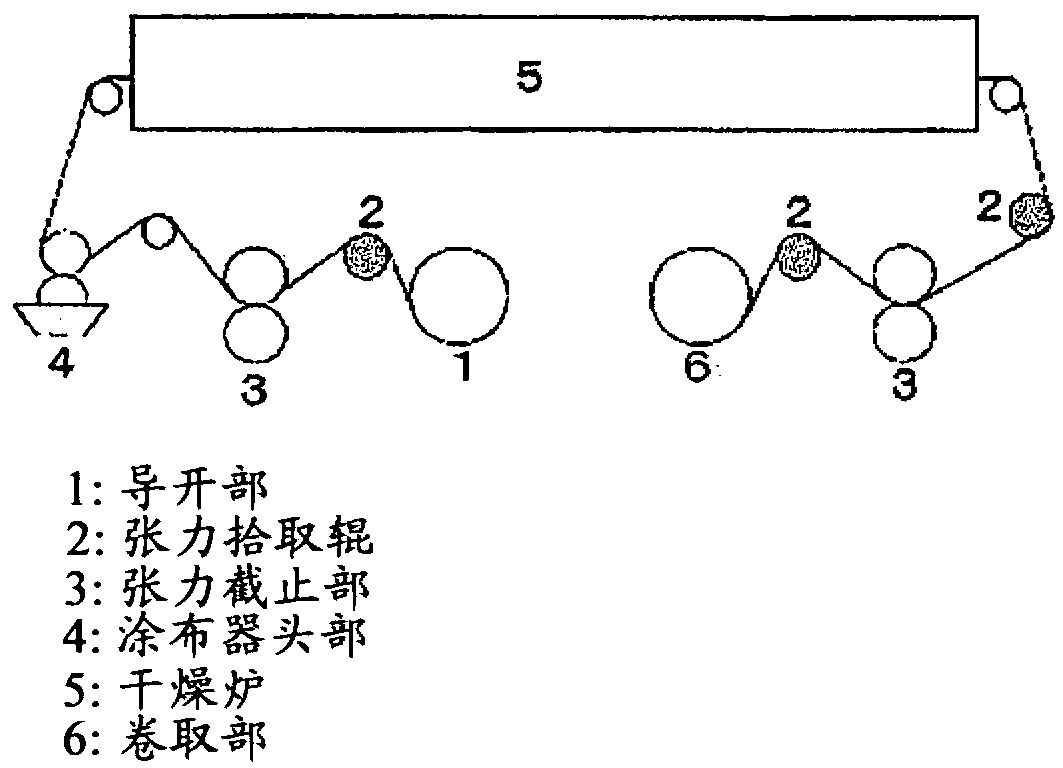

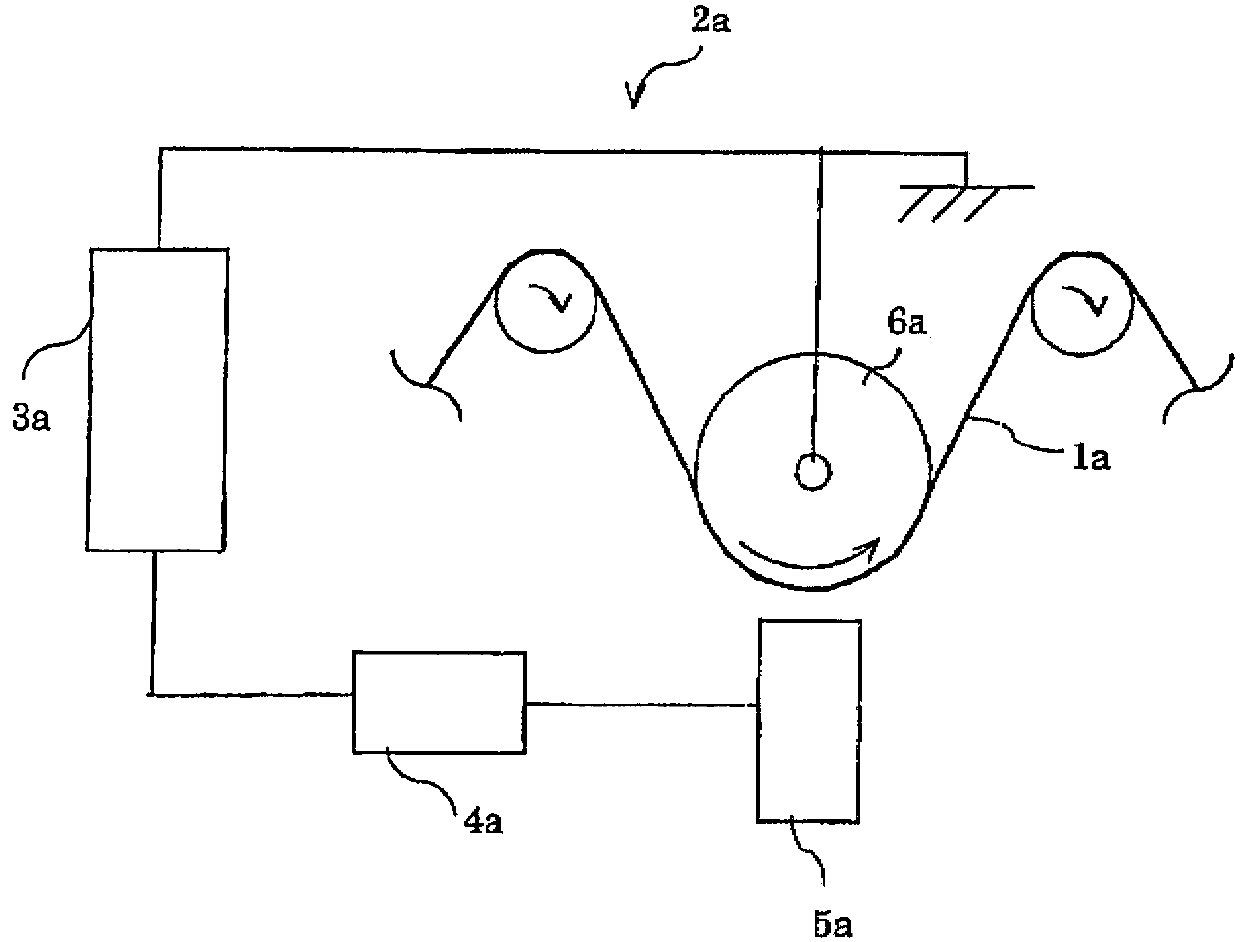

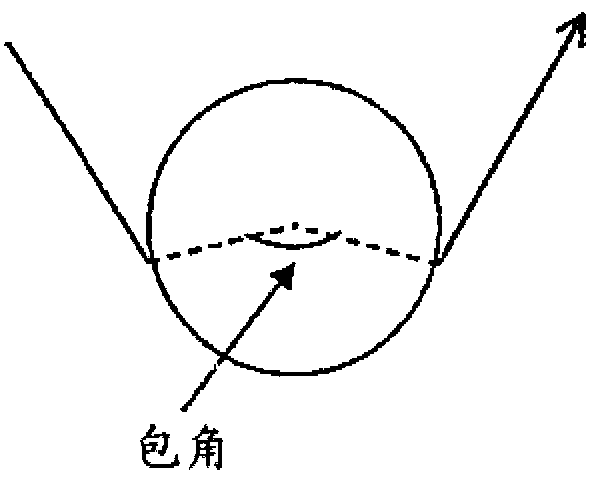

[0211] Use a small-diameter gravure coating roll (roller diameter is 62mm, gravure engraving: grid (depth is 290μm, unit volume is 145cm 3 / m 2 )) coating the above-mentioned coating liquid to form a coating layer on the base material of the above-mentioned polyolefin resin porous membrane. Here, the tension (Ta) of the film in the drying step was controlled to 29 N / m, and the tension (Tb) of the film in the winding step was controlled to 25 N / m. The values of Ta and Tb are measured by tension detectors connected to respective tension pick-up rollers.

Embodiment 2

[0213] Coating was performed in the same manner as in Example 1, except that the tension (Ta) of the film in the drying step was controlled to 40 N / m, and the tension (Tb) of the film in the winding step was controlled to 35 N / m.

Embodiment 3

[0215] Coating was performed in the same manner as in Example 1, except that the tension (Ta) of the film in the drying step was controlled to 35 N / m, and the tension (Tb) of the film in the winding step was controlled to 30 N / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com