TPE-base composite film material and preparation method thereof

A technology of composite membrane and composite stabilizer, which is applied in the field of TPE-based composite membrane materials and preparation, can solve problems such as difficulty in replacement, achieve the effects of reducing costs, increasing softness and fluidity, and improving creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

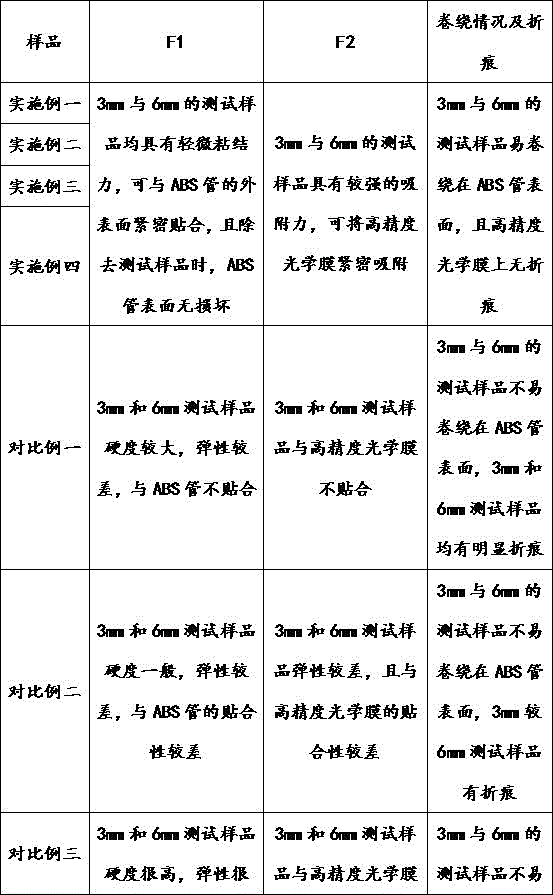

Examples

Embodiment 1

[0046] (1) According to 100 parts of SEBS, 40 parts of PP, 10 parts of CPE, 10 parts of sodium carboxymethyl cellulose, 2 parts of dibutyltin dilaurate, 2 parts of dibutyltin maleate, 5 parts of paraffin-calcium stearate, 5 parts of paraffin oil, 5 parts of naphthenic oil, and 1 part of antioxidant are used for batching;

[0047] (2) Add the materials mentioned in step (1) into the high mixer in turn, and mix at 40~60°C for 10 minutes to obtain the premix;

[0048] (3) Add the premixed material obtained in step (2) into a twin-screw extruder to extrude and granulate, the extrusion temperature is 170~200°C, and the head temperature is 190°C;

[0049] (4) Blow molding the masterbatch prepared in step (3) to obtain a TPE-based composite film material.

Embodiment 2

[0051] (1) According to 110 parts of SEBS, 60 parts of PP, 20 parts of MBS, 10 parts of hydroxyethyl cellulose, 3 parts of dibutyltin dilaurate, 3 parts of dibutyltin maleate, 5 parts of paraffin-lead stearate, paraffin wax 8 parts of oil, 8 parts of naphthenic oil, and 2 parts of antioxidant are used for batching;

[0052] (2) Add the materials mentioned in step (1) into the high mixer in turn, and mix at 40~60°C for 10 minutes to obtain the premix;

[0053] (3) Add the premixed material obtained in step (2) into a twin-screw extruder to extrude and granulate, the extrusion temperature is 170~200°C, and the head temperature is 190°C;

[0054] (4) Blow molding the masterbatch prepared in step (3) to obtain a TPE-based composite film material.

Embodiment 3

[0056] (1) According to SEBS 120 parts, PP 80 parts, light CaCO 3 30 parts, 20 parts of sodium carboxymethyl cellulose, 4 parts of dibutyltin dilaurate, 4 parts of dibutyltin maleate, 10 parts of paraffin-calcium stearate, 12 parts of paraffin oil, 12 parts of naphthenic oil, antioxidant 2 parts of the agent are used for batching;

[0057] (2) Add the materials mentioned in step (1) into the high mixer in turn, and mix at 40~60°C for 10 minutes to obtain the premix;

[0058] (3) Add the premixed material obtained in step (2) into a twin-screw extruder to extrude and granulate, the extrusion temperature is 170~200°C, and the head temperature is 190°C;

[0059] (4) Blow molding the masterbatch prepared in step (3) to obtain a TPE-based composite film material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com