Adhesive for flexible display and flexible display assembly layer

A flexible display and adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, polymer adhesive additives, etc., can solve problems such as insufficient bending performance, and achieve modulus stability. , to meet performance requirements and improve the effect of bending life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

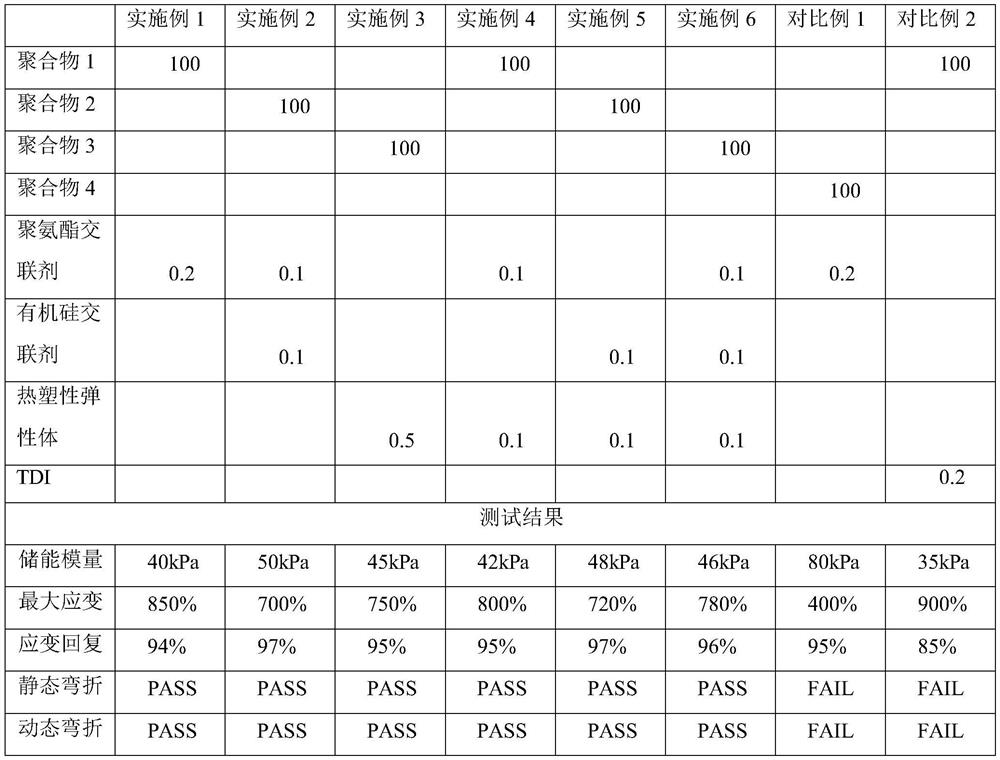

[0057] Mix 100 parts of acrylate polymer 1 and 0.2 parts of polyurethane crosslinking agent evenly, coat it on the polyester release film, put it in an oven at 80°C for 5 minutes, wait for the solvent to evaporate completely, and then apply another layer of polyester release film. type film, put the formed three-layer structure film in a 60°C oven for 48hrs, and then use 1000mj / cm 2 UV energy is used for curing to form a cross-linked network structure.

[0058] Examples 2-6 and Comparative Example 1 were cross-linked and cured according to the formulation information in Table 1 and the same process as in Example 1. In comparative example 2, only thermal curing was performed without subsequent UV curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com