Copper crinkle removing mechanism

A technology for removing copper and clamping cranes, applied in the field of processing equipment, can solve the problems of inability to completely remove the air from the copper foil, centrifugal film, and wrinkled copper foil, and achieve the effects of high production yield, ensuring parallelism, and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

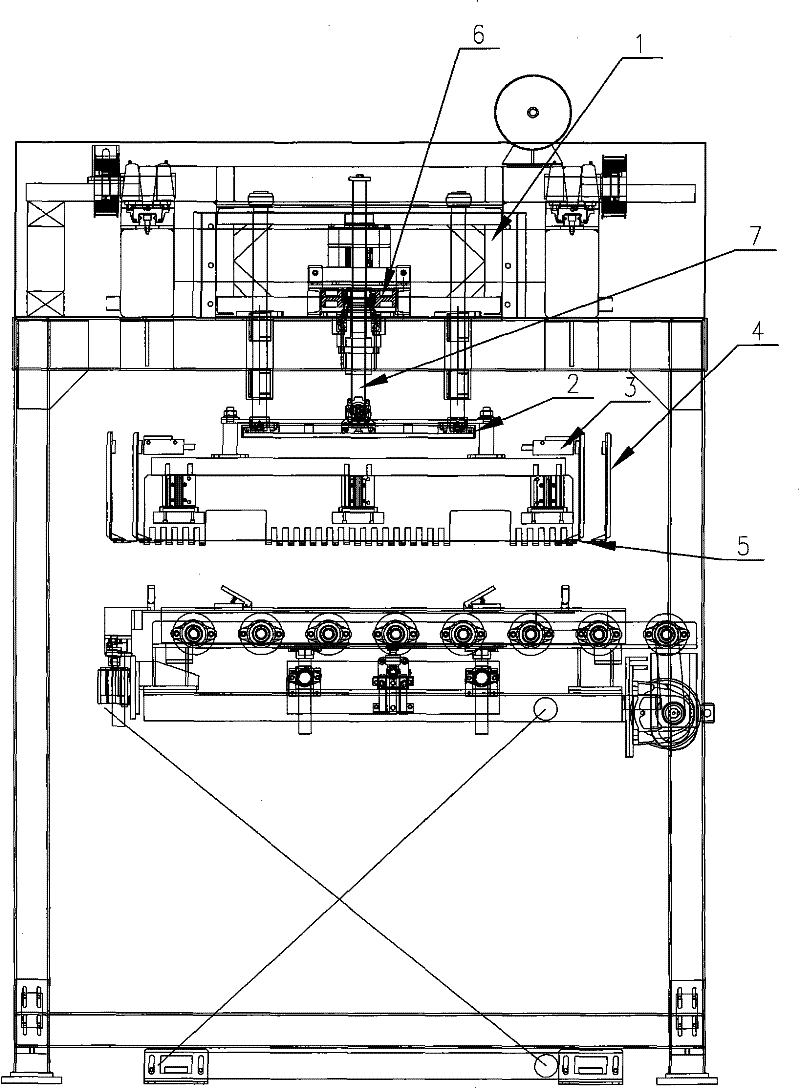

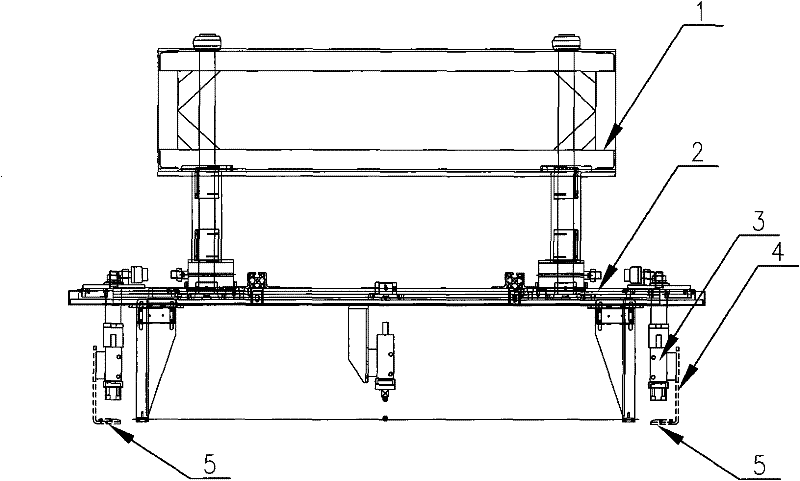

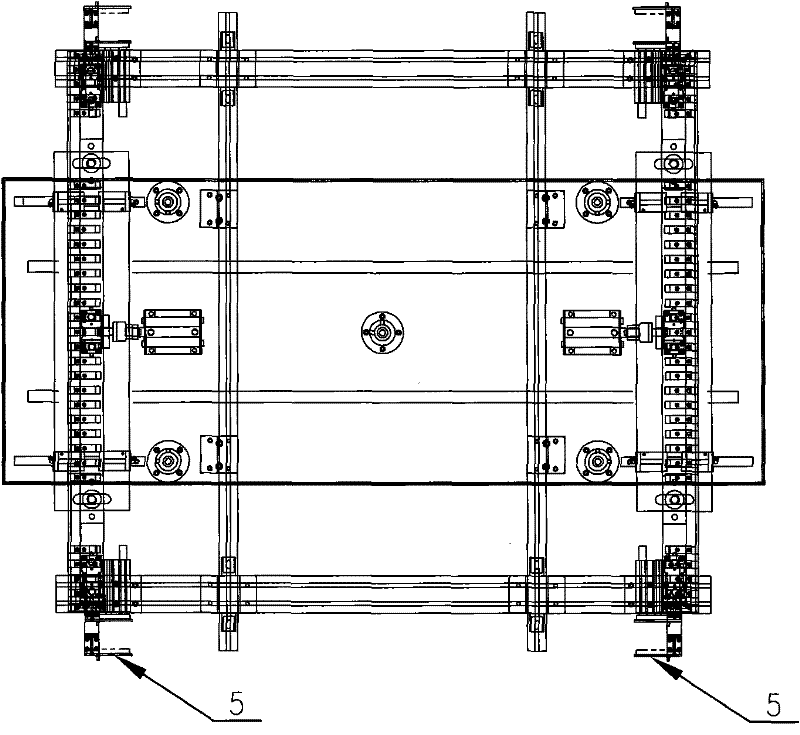

[0015] Embodiment: A mechanism for removing copper wrinkles, including a sandwich clamping machine 1, a support frame 2, a cylinder 3, a mirror bending plate 4 and a blade 5, based on the direction of use, the sandwich clamping machine 1 can drive the support frame 2 Moving along the longitudinal direction, at least two cylinders 3 are fixed on both sides of the lower end of the support frame 2 in a symmetrical state. Fixed connection, the side walls of the lower ends of the two mirror-bending plates 4 are fixed with symmetrically distributed spatulas 5 respectively. When in use, first place the sandwich plate (a steel plate sandwiched between two layers of copper foil) On the base plate at the lower end of the clamping machine 1, the sandwich clamping machine 1 lowers to the set position with the support frame 2, and the piston rods of the cylinders 3 on both sides of the support frame 2 contract, so that the blade 5 is inserted into the steel plate and steel plate of the sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com