Water thermal insulative reflecting paint

A technology of reflective paint and thermal insulation material, applied in the field of paint, can solve the problems of unsatisfactory thermal insulation effect, complex manufacturing method, single thermal insulation channel, etc., and achieve the effects of good thermal insulation effect, good decorative effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

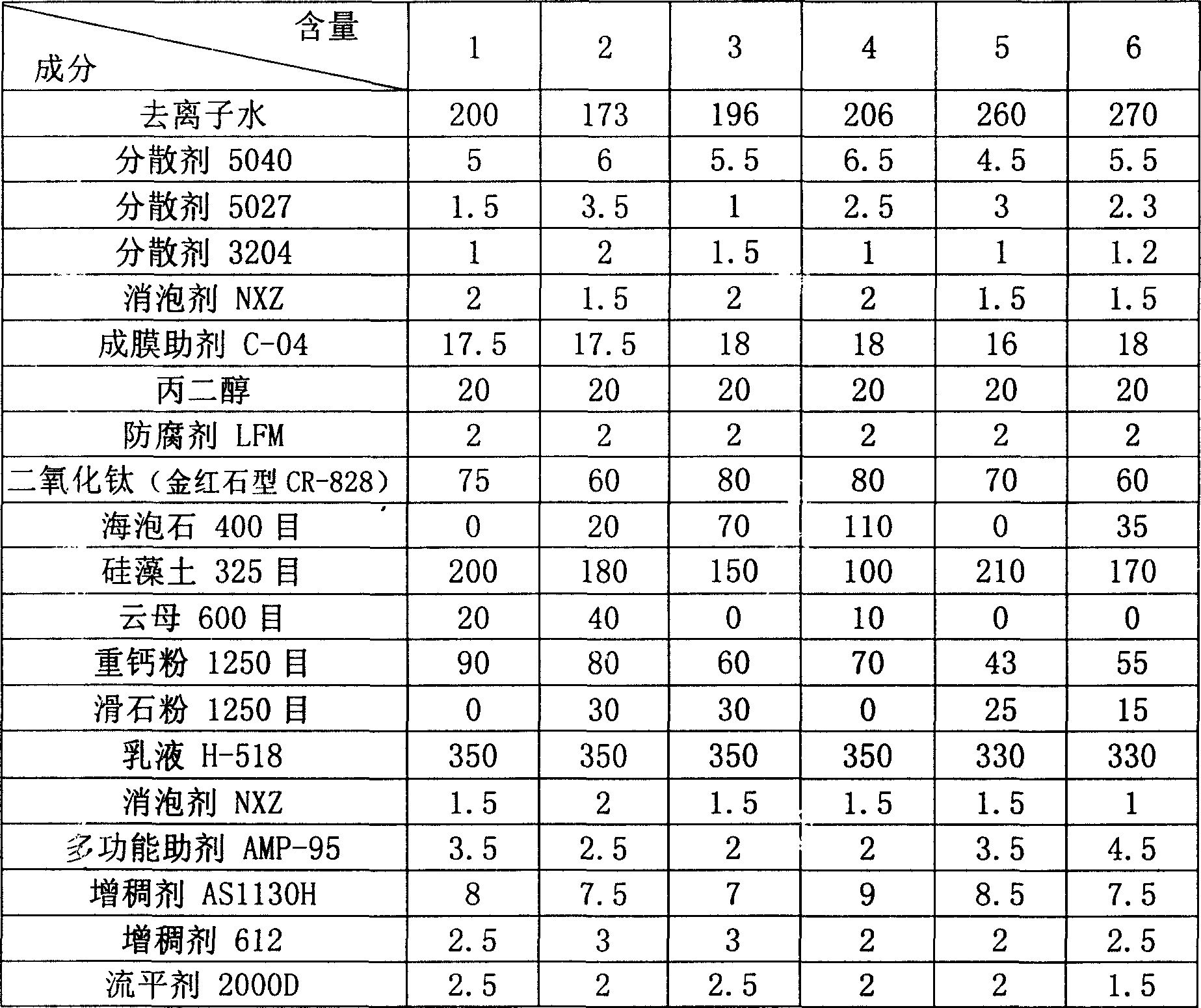

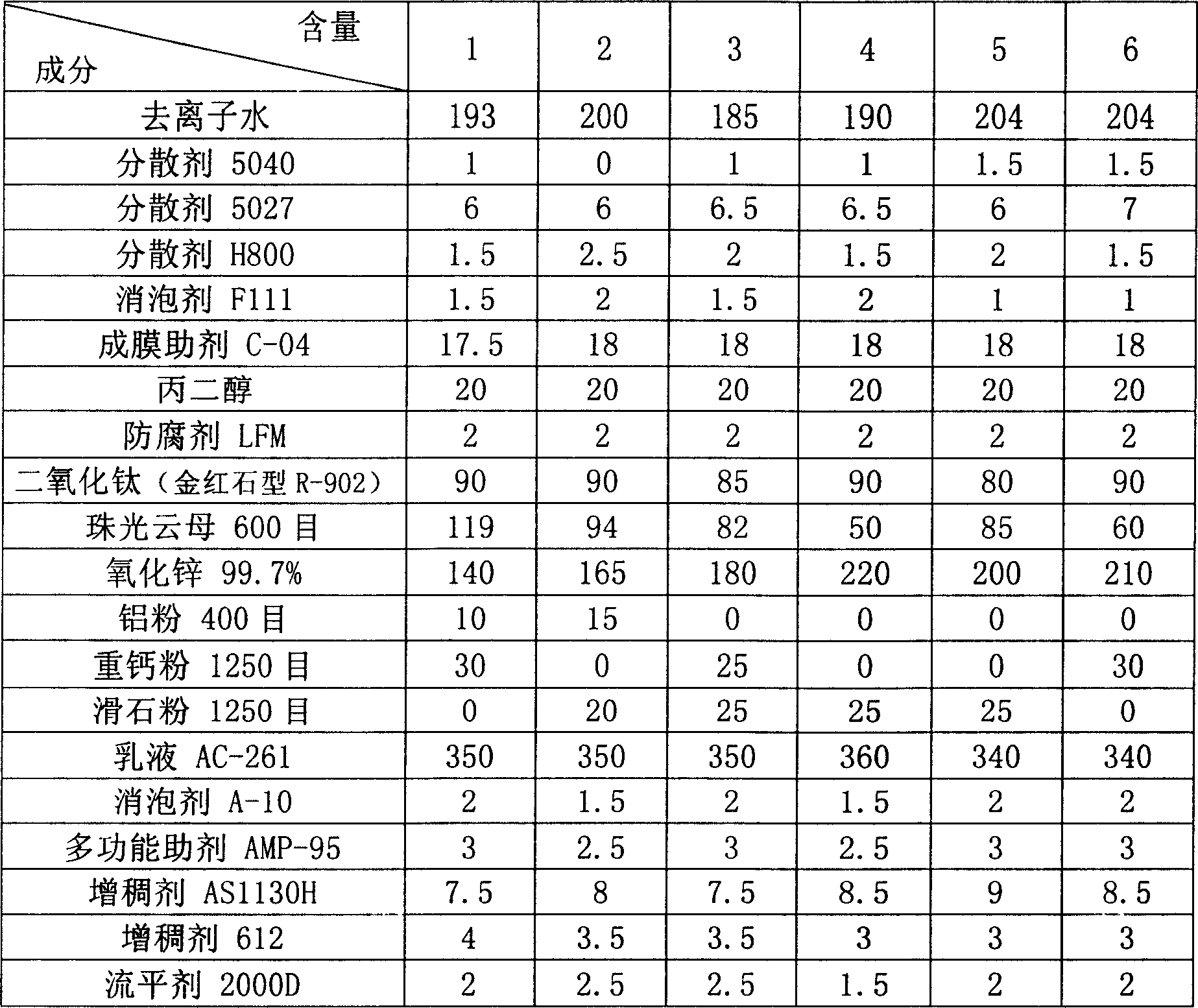

[0028] Specific examples of the present invention are shown in Table 1 and Table 2. Table 1 is specific examples 1-6 of the primer of the water-based heat-shielding and reflective coating of the present invention. Table 2 is specific examples 1-6 of the top coat of the water-based heat-shielding and reflective coating of the present invention.

[0029] Table 1

[0030]

[0031] Table 2

[0032]

[0033] Use the water-based heat-insulating reflective coating of the present invention, after treating the building surface in a conventional manner, brush (or roll or spray) the heat-insulating primer 3 times, and the reflective topcoat 2 times. Coating thickness is 0.7±0.1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com