Molding equipment for functional chemical fiber cotton processing

A molding equipment and technology of chemical fiber cotton, which is applied in the field of chemical fiber cotton processing, can solve the problems of changing the thickness of chemical fiber cotton semi-finished products, and achieve the effects of fast forming time, complete shape and reduced fluid flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

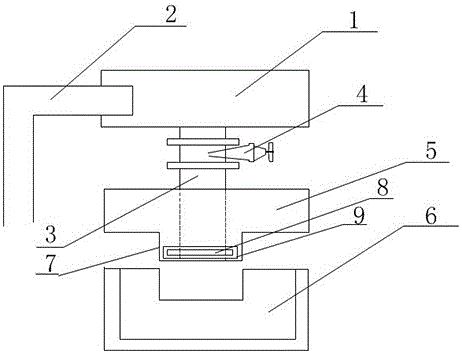

[0027] Such as figure 1 As shown, a molding device for functional chemical fiber cotton processing of the present invention includes a mold base, the mold base is provided with a mold cavity, and also includes a feeding device for feeding the mold base;

[0028] The feeding device includes a hot melt chamber 1, a feed pipe 2 connected to the hot melt chamber, and a discharge pipe 3. The discharge port of the discharge pipe 3 is located above the mold cavity, and the discharge pipe 3 is equipped with the first control valve 4;

[0029] Described mold base comprises upper mold base 5, lower mold base 6, and upper mold base 5 is positioned at the top of lower mold base 6, and described mold cavity is positioned at the upper surface of lower mold base 6, and upper mold base 5 is provided with mold cavity shape The matching pressing device 7, the discharge pipe 3 passes through the upper mold base 5 and the pressing device 7, and the side surface of the pressing device 7 is provid...

Embodiment 2

[0032] Based on Embodiment 1, a hydraulic column is connected below the lower mold base 6 . The hydraulic column can automatically lift the lower mold base, and other telescopic devices can also be used to replace it, such as electric lifting table, hand lift, screw lift, etc.

Embodiment 3

[0034] Based on the above-mentioned embodiment, the mold base adopts a closed mold base. The mold base is not divided into an upper mold base and a lower mold base. The hole is injected with raw material, and after the raw material fills the mold cavity, the mold base itself has a pressing effect, and there is no need to install a pressing device, that is, a lifting device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com