Production process of composite cardboard

A production process and cardboard technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of uncontrollable bonding, air bubbles and wrinkles, and many cardboard waste products, and achieve the effects of saving raw materials and costs, improving efficiency, and low waste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A composite cardboard production process, comprising the following steps:

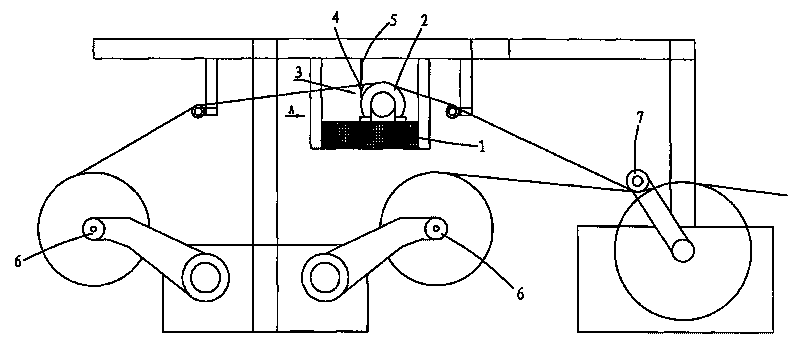

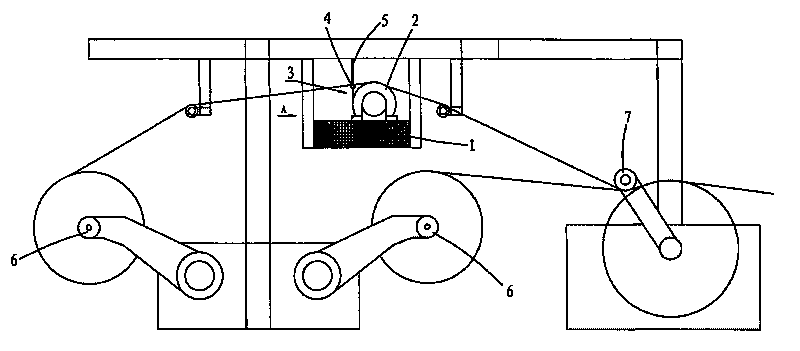

[0017] Such as figure 1 , figure 2 As shown, A, a roll of cardboard and a roll of bobbin are respectively placed on two rotatable horizontal shafts 6, and the bobbin and the bobbin are arranged one after the other;

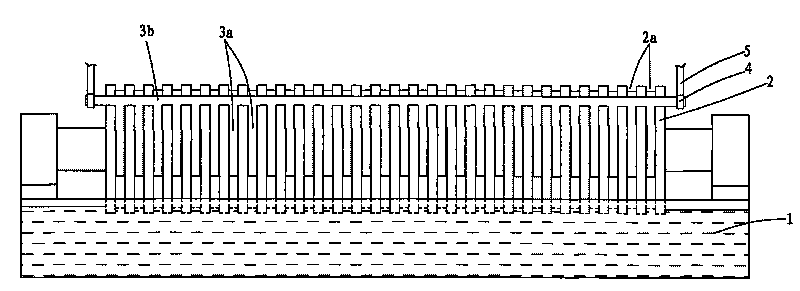

[0018] B. Pull out the paper head of the boxboard paper roll, and pass over the upper rubber roller 2 of the sizing device, and the upper rubber roller 2 rolls to apply glue to the lower surface of the boxboard paper. Roller 2 and squeegee plate 3 are made up, and rubber groove 1 two ends side walls are supported by bearing to have upper rubber roller 2, and bearing is installed in the respective bearing seat of both sides. The lower part of the upper rubber roller 2 is located in the rubber groove 1, and the outer circumference of the upper rubber roller 2 is evenly opened with a ring groove 2a. The rubber plate 3 is composed of a scraper 3a and a cross bar 3b, the scraper 3a i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com