Super-sticky precoating and preparation method and application thereof

A technology of pre-coated film and polypropylene film, which is applied in the direction of chemical instruments and methods, adhesives, film/sheet adhesives, etc., can solve the problems of film release, air bubbles, and weak adhesion, etc., and achieve strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

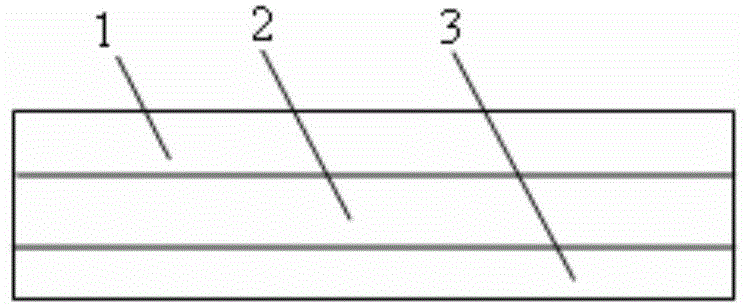

Image

Examples

preparation example Construction

[0025] The present invention provides a kind of preparation method of super sticky precoat film described in above-mentioned technical scheme, comprises the following steps:

[0026] Coating the hot melt adhesive on the substrate layer to obtain a super-adhesive pre-coating film intermediate;

[0027] The polyethyleneimine solution is coated on the surface of the hot-melt adhesive layer of the super-adhesive pre-coating film intermediate, and dried to obtain a super-adhesive pre-coating film.

[0028] In the invention, the hot-melt adhesive is coated on the base material to obtain a super-adhesive pre-coating film intermediate.

[0029] In the present invention, the types and sources of the hot-melt adhesive and the base material are consistent with the above-mentioned technical solutions, and will not be repeated here.

[0030] The present invention has no special limitation on the coating method, and the coating technical solution well known to those skilled in the art can ...

Embodiment 1

[0052] The number-average molecular weight is 20000g / mol ethylene-acetate copolymer (purchased from Samsung, Korea) to be coated on the biaxially oriented polypropylene film substrate (purchased from Furonghui (Fujian) Industrial Co., Ltd. ) to obtain a super-adhesive pre-coating film intermediate, the thickness of the substrate layer in the super-adhesive pre-coating film intermediate is 15 μm, and the thickness of the hot melt adhesive layer is 15 μm;

[0053] Mix 0.88 kg of polyethyleneimine (number average molecular weight: 50000 g / mol) aqueous solution with a solid content of 19%, 50 kg of methanol and 5 kg of isopropanol to obtain a polyethyleneimine solution;

[0054] After obtaining the super-adhesive pre-coating film intermediate, the above-mentioned polyethyleneimine solution is coated on the surface of the hot-melt adhesive layer of the super-adhesive pre-coating film intermediate, and the line speed of coating is 80 meters / min, and then on the coating machine Dry w...

Embodiment 2

[0057] The number-average molecular weight is 20000g / mol ethylene-acetate copolymer hot-melt adhesive (purchased in Mitsui Co., Ltd., Japan) to be coated on the biaxially oriented polyester film (purchased in Yingkou Kanghui Petrochemical Co., Ltd.) by roll coating, Obtain a super sticky precoat film intermediate, the thickness of the substrate layer in the super sticky precoat film intermediate is 15 μm, and the thickness of the hot melt adhesive layer is 15 μm;

[0058] Mix 0.82 kg of polyethyleneimine (number average molecular weight: 100000 g / mol) aqueous solution with a solid content of 19%, 45 kg of methanol and 4 kg of isopropanol to obtain a polyethyleneimine solution;

[0059] After obtaining the super-adhesive pre-coating film intermediate, the above-mentioned polyethyleneimine solution is coated on the surface of the hot-melt adhesive layer of the super-adhesive pre-coating film intermediate, and the line speed of coating is 75 meters / min, and then on the coating mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com