Laminating machine

A laminating machine, plastic film technology, applied in printing machines, general parts of printing machinery, printing and other directions, can solve the problems of film residue, film breaking, wrinkles, etc., to avoid the effect of film residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

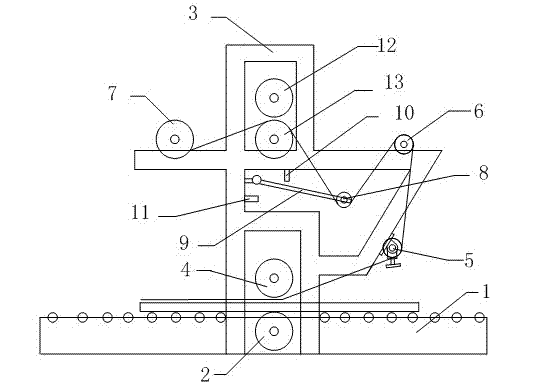

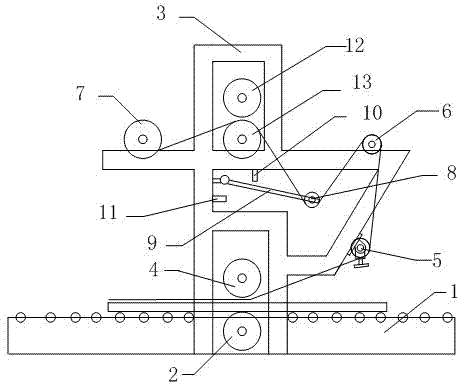

[0012] Such as figure 1 The laminating machine shown includes a conveying roller table 1, which is provided with a lower drive wheel 2, and its special feature is that a bracket 3 is arranged above the conveying roller table 1 used in the present invention, and a support 3 is arranged on the support 3 is provided with a lower driven wheel 4 corresponding to the top of the lower driving wheel 2 . At the same time, considering the anti-wrinkle of the viscose plastic film, a flattening regulator 5 is arranged on the outside of the bracket 3 . Specifically, the input end of the used flattening regulator 5 is provided with a passive transmission wheel 6, and the input end of the passive transmission wheel 6 is provided with a conveying control assembly. Correspondingly, the input end of the conveying control assembly is provided with a membrane separation assembly, and the input end of the membrane separation assembly is provided with an adhesive plastic film input wheel 7 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com