Composite fireproof glass and preparation method thereof

A technology of fireproof glass and fireproof glue, applied in chemical instruments and methods, glass/slag layered products, adhesive additives, etc. Good impact performance, good comprehensive performance, and the effect of improving the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

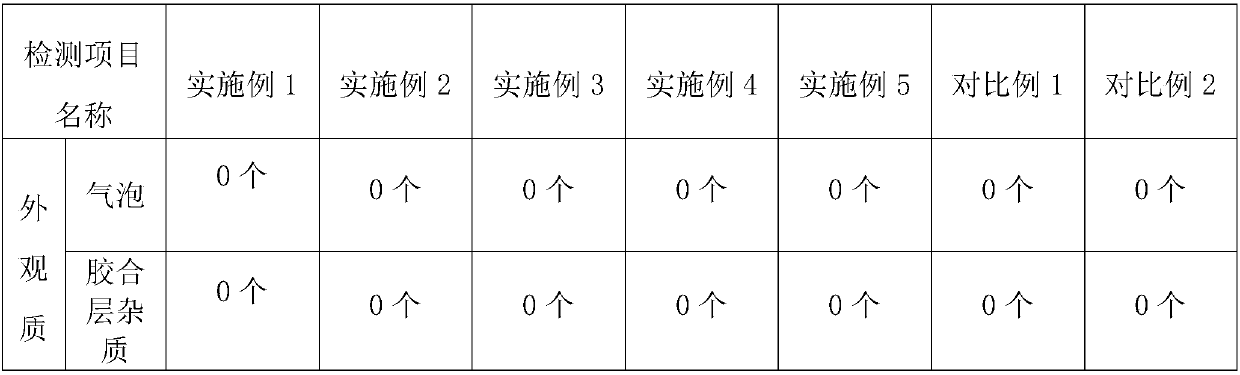

Examples

Embodiment 1

[0031] A composite fireproof glass, comprising two pieces of flat glass and fireproof glue, the fireproof glue is arranged in the cavity formed by the two pieces of flat glass, and the fireproof glue is composed of the following components by weight:

[0032] 125 parts of acrylamide, 1800 parts of water, 420 parts of sodium chloride, 1 part of phosphoric acid, 5 parts of ammonium persulfate, 5 parts of sodium metabisulfite, 0.168 parts of methylenebisacrylamide.

[0033] A preparation method of composite fireproof glass, comprising the following steps:

[0034] S1. According to the formula of the above-mentioned fireproof glue, weigh each component for later use;

[0035] S2. Prepare methylenebisacrylamide aqueous solution, ammonium persulfate aqueous solution, and sodium metabisulfite aqueous solution respectively, wherein, in methylenebisacrylamide aqueous solution, the mass ratio of methylenebisacrylamide to water is 1:832, and persulfuric acid In the ammonium aqueous solu...

Embodiment 2

[0043] A composite fireproof glass, comprising two pieces of flat glass and fireproof glue, the fireproof glue is set in the cavity formed by the two pieces of flat glass,

[0044] The fireproof adhesive consists of the following components by weight:

[0045] 128 parts of acrylamide, 1870 parts of water, 426 parts of sodium chloride, 1.3 parts of phosphoric acid, 6 parts of ammonium persulfate, 6 parts of sodium metabisulfite, 0.175 parts of methylenebisacrylamide.

[0046] A kind of preparation method of composite fireproof glass is the same as embodiment 1.

Embodiment 3

[0048] A composite fireproof glass, comprising two pieces of flat glass and fireproof glue, the fireproof glue is set in the cavity formed by the two pieces of flat glass,

[0049] The fireproof adhesive consists of the following components by weight:

[0050]Acrylamide 130 parts, water 1900 parts, sodium chloride 430 parts, phosphoric acid 1.5 parts, ammonium persulfate 7 parts, sodium metabisulfite 7 parts, methylenebisacrylamide 0.18 parts.

[0051] A kind of preparation method of composite fireproof glass is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com