Patents

Literature

715 results about "Sodium disulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium metabisulfite or sodium pyrosulfite (IUPAC spelling; Br. E. sodium metabisulphite or sodium pyrosulphite) is an inorganic compound of chemical formula Na2S2O5. The substance is sometimes referred to as disodium (metabisulfite).

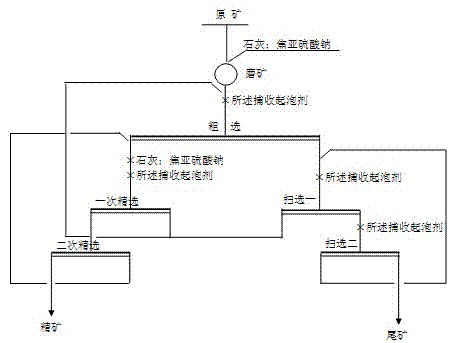

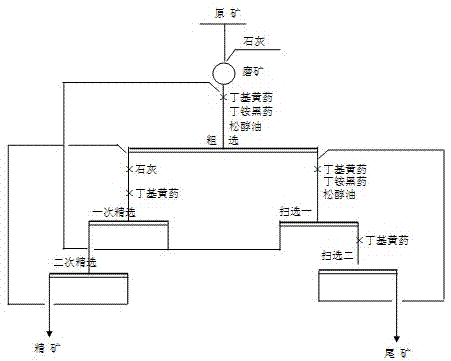

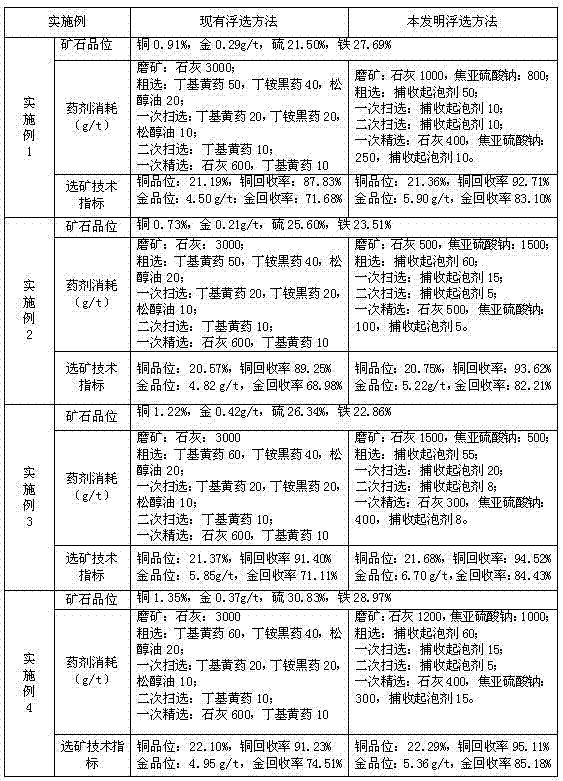

Method for floating high-sulfur gold-bearing copper ore

ActiveCN103691569AEnhanced inhibitory effectImprove beneficiation indexFlotationPropionitrileEthyl group

The invention discloses a method for floating high-sulfur gold-bearing copper ore, which aims at solving the problems that the existing beneficiation method is lower in copper and gold recovery rate under high-alkali condition, and problems that xanthate and black powder are adopted as high-sulfur gold-bearing copper ore collecting agents, the collecting power is stronger, the selectivity is poor, the separation difficulty of copper and sulfur can be aggravated and the consumption of inhibitors is increased. The method comprises the steps of by adopting lime and sodium metabisulfite as an ore pulp pH regulator and a pyrite inhibitor, and the mixture of isopropyl xanthogen propionitrile ester, black powder acid and ethyl dithiocarboxyl propionitrile ester according to certain proportion as a collecting foaming agent, carrying out ore grinding, rough concentration, primary scavenging, secondary scavenging, primary concentration, and secondary concentration on a crude ore, thus realizing the high-efficiency recovery on copper and gold in the high-sulfur gold-bearing copper ore. According to the method, through reasonable combination and addition of medicaments, the selective adsorption of the collecting agent on target mineral-copper pyrite and other copper sulfide minerals and gold minerals can be reinforced, and the copper recovery rate and the gold recovery rate can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Low-salt pickled fermented Allium chinense and processing method thereof

InactiveCN101926446ARich flavorPreserve the crispnessFood preparationAcetic acidSodium metabisulfite

The invention relates to a low-salt pickled fermented Allium chinense and a processing method thereof. The pickled fermented Allium chinense is prepared by the steps of: taking a fresh Allium chinense; removing fibrous roots and washing; adding table salt, drinking water, glacial acetic acid, citric acid and sodium metabisulfite to carry out primary fermentation for 10 to 12 days; taking the fermented Allium chinense; adding the table salt, the drinking water, the glacial acetic acid and the citric acid to carry out secondary fermentation for 30 to 60 days; proportionally mixing the fermented Allium chinense in the second time with soup; then adding dried red pepper rings; and sterilizing and cooling. The product of the invention has stable quality and low content of sulfur dioxide with preferable preservation of color, brittleness and nutritious elements of the Allium chinense, and has longer shelf life.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

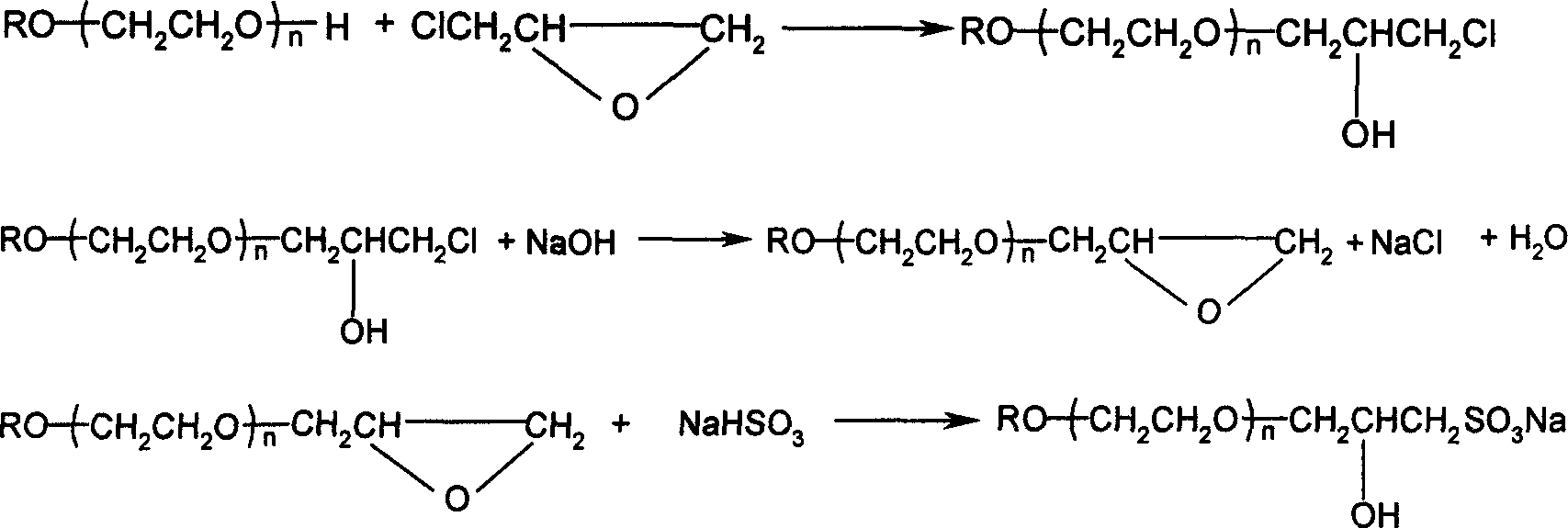

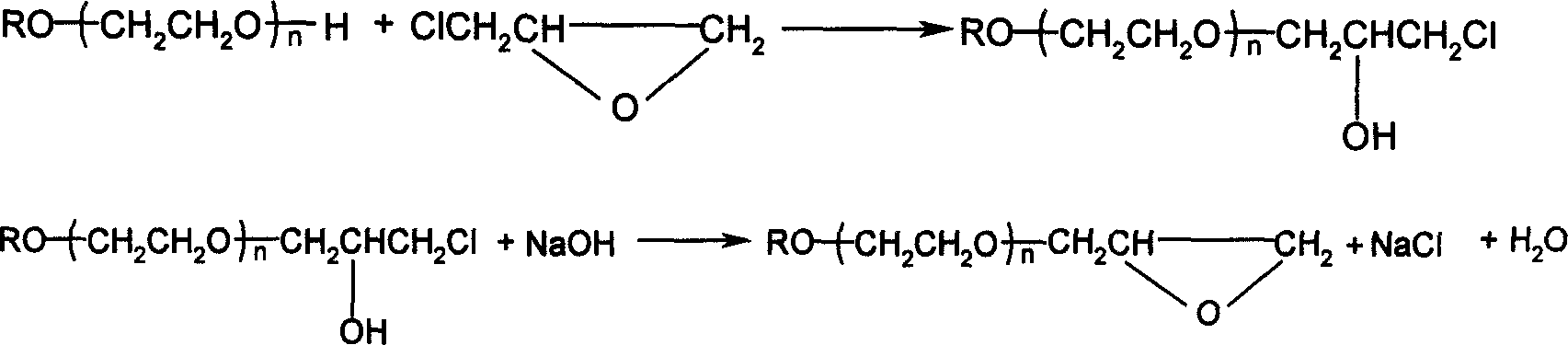

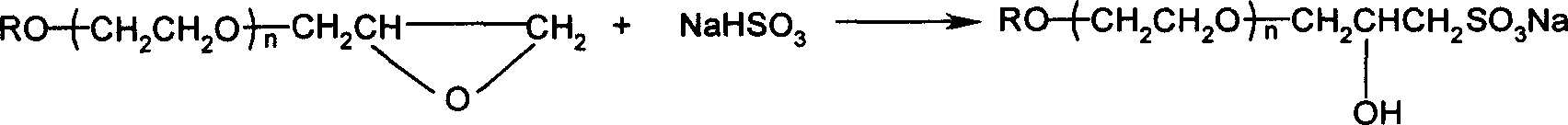

Anti-salt type thicking oil reducing viscosity agent and preparation process thereof

The invention provides a salt-resistant crude oil viscosity reductant and its preparing method, and it is polyoxyethylene ether hydroxy propanesulfonate synthesized by using a nonionic surfactant containing special oxyethylene chain segment as raw material and the preparing method includes 1, making polyoxyethylene ether nonionic surfactant react with epoxy chloropropane to obtain polyoxyethylene ether chlorohydroxy propane; 2, making the product in step 1 reacts with NaOH to obtain polyoxyethylene ether epoxy propane; 3, sulfonating the product in step 2 with sodium disulfite to obtain it. Its character: by selecting polyoxyethylene alkyl alcohol (phenol) ether nonionic surfactant of different oxyethylene chain segments as raw materials, it can prepare crude oil viscosity reductants of different salt resisting properties.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

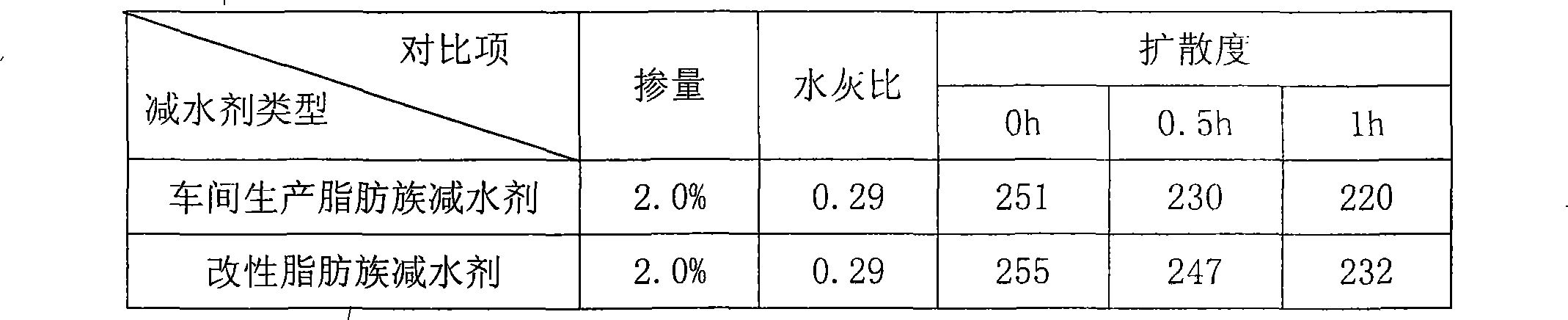

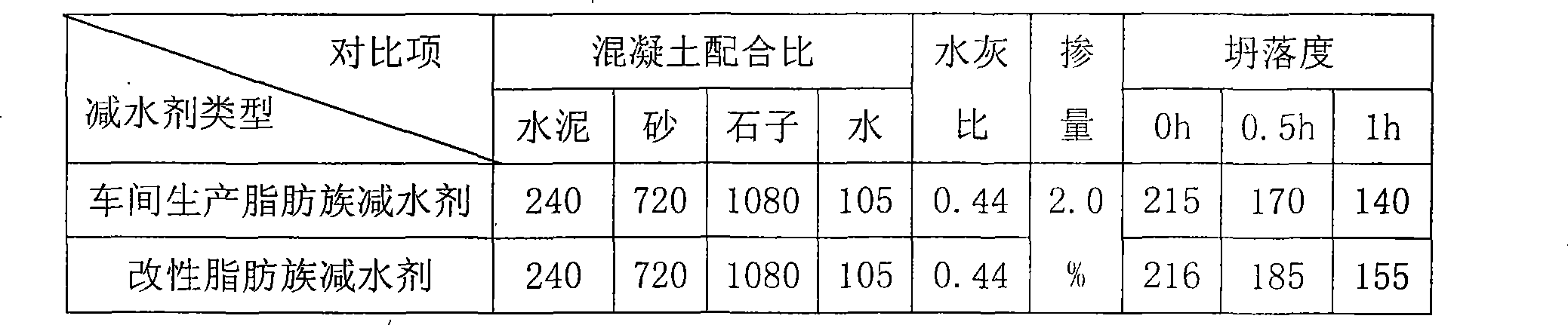

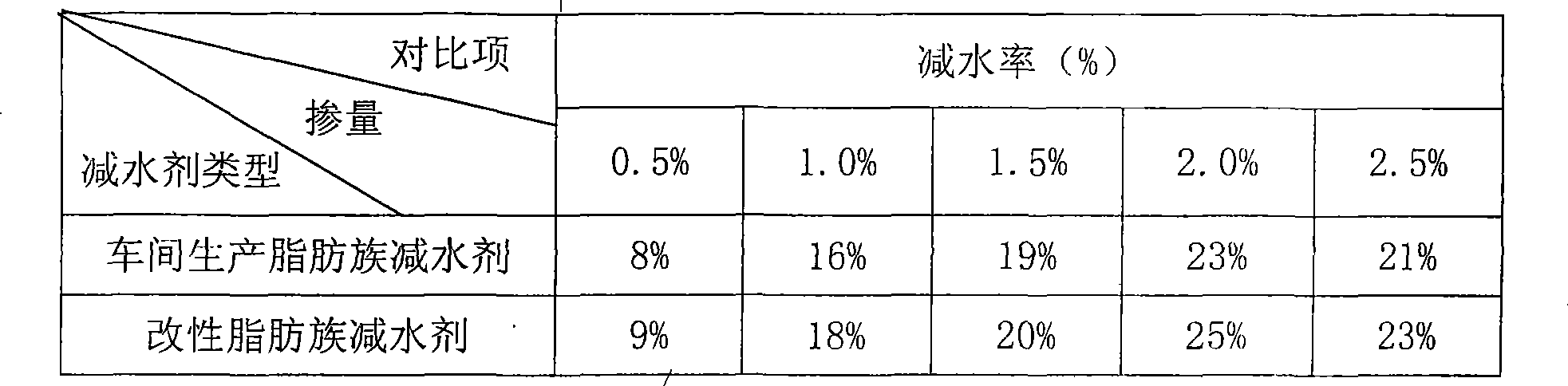

Modified aliphatic water reducing agent and preparation method

The invention discloses a method for preparing a modified aliphatic water reducing agent. The water reducing agent is a high-performance water reducing agent synthesized by taking acetone, formaldehyde and sodium metabisulfite as main raw materials and assisting with a proper amount of active agent and accelerating agent under certain conditions. The method comprises the following steps that: weighed tap water, sodium metabisulfite, sodium hydroxide and acetone are added into a four-mouth boiling flask with a reflux condenser tube, a thermometer and a stirrer, and are mixed evenly, then an accelerating agent, namely azodiisobutyronitrile is added into the flask, the temperature is increased, and the thermal insulation is performed after a sulfonation reaction; and the formaldehyde is dripped after the sulfonation reaction is finished, and the dripping speed is controlled. An acrylic acid active agent is added into the obtained product to obtain the modified aliphatic water reducing agent. The method is simple, is easy for industrialized production, reduces production cost, improves working performance (comprising the water-reducing rate and the flowability, workability, water retention property, plasticity retention performance and compressive strength of prepared concrete), and has obvious economic benefit and social benefit.

Owner:武汉市联合石油化工有限责任公司

Method for preparing water-coal-slurry additive taking enzymatic hydrolysis lignin as raw material

InactiveCN101921639ARetain chemical activityHigh purityLiquid carbonaceous fuelsCelluloseActive agent

The invention provides a method for preparing a water-coal-slurry additive taking enzymatic hydrolysis lignin as a raw material. In the method, the chemical activity of the enzymatic hydrolysis lignin is utilized to directly perform polycondensation with sodium hydrogen sulfite, sodium metabisulfite, acetone and methanal to a prepare enzymatic hydrolysis lignin-sulphonated acetone-methanal condensation polymer (LSAF); the enzymatic hydrolysis lignin-sulphonated acetone-methanal condensation polymer (LSAF) is compatible with other types of surfactants, and is compounded with the surfactants, such as sodium dodecyl benzene sulfonate, PVA, carboxymethyl cellulose sodium and the like to prepare the water coat slurry which has higher stability and lower viscosity; and the liquidity of the water coat slurry is improved. The enzymatic hydrolysis lignin replaces the partial petrochemical raw materials to prepare modified high molecular materials, which not only lowers the cost of high molecular materials, but also can save the consumption of the petrochemical materials, and can generate significant social benefit; and the processing technique for preparing the water-coal-slurry additive taking the enzymatic hydrolysis lignin as a raw material is simple, is easy to implement and has good effect.

Owner:FUZHOU UNIV

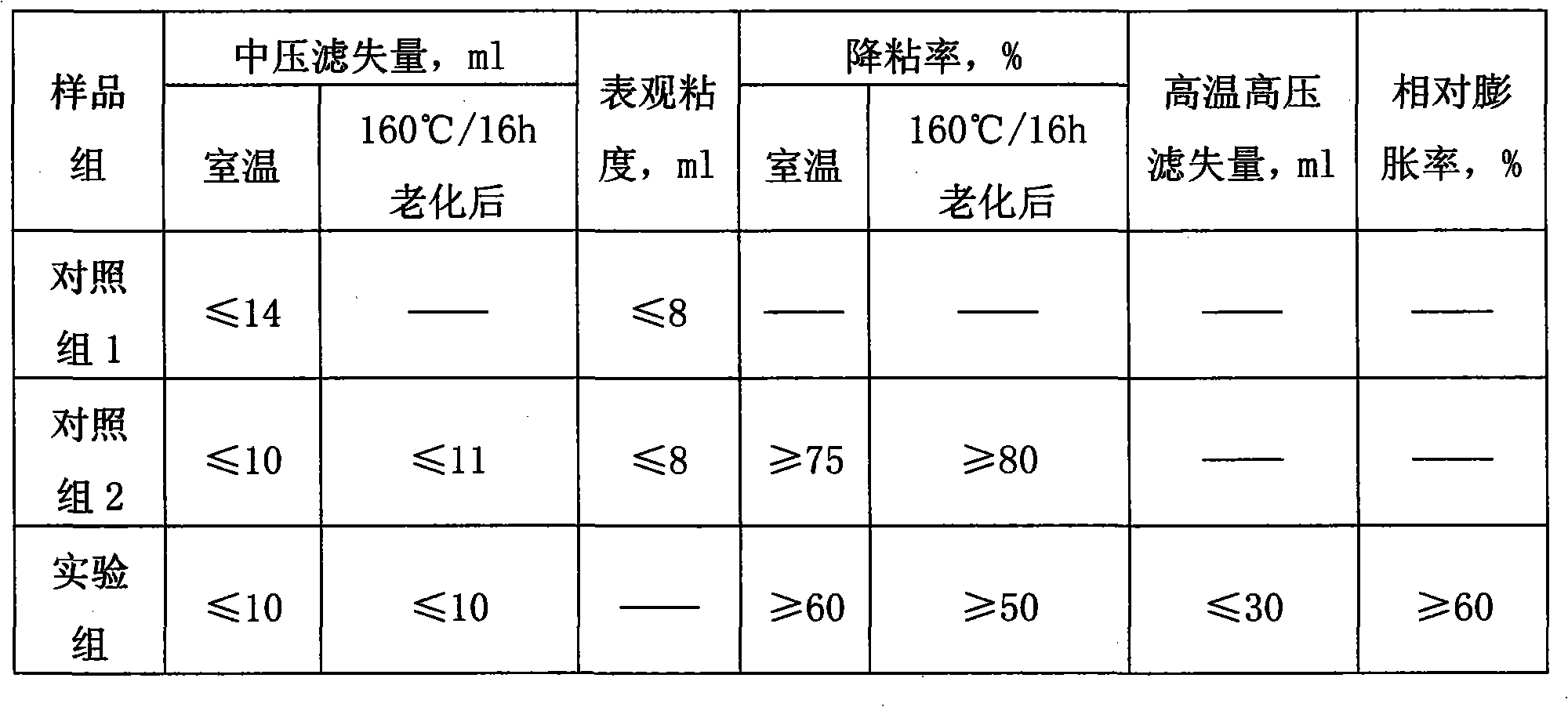

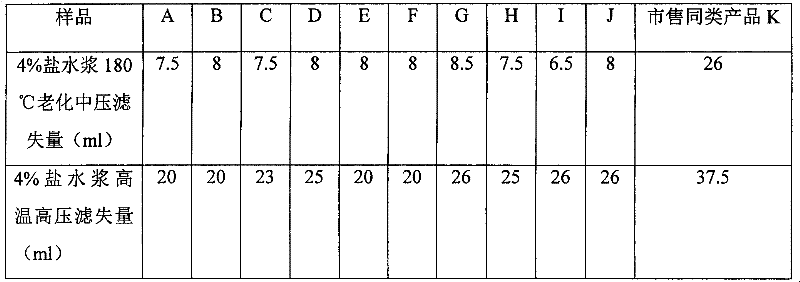

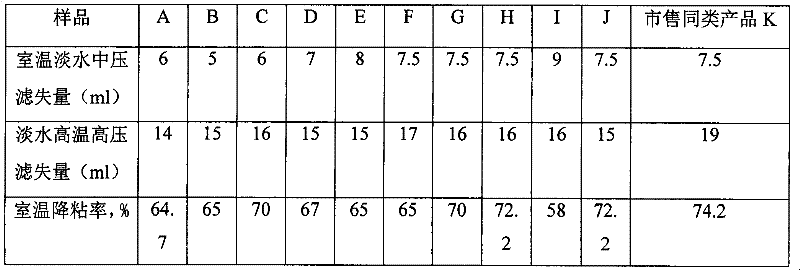

Anti-sloughing diluted filtration reducing agent for drilling fluid and preparation method thereof

ActiveCN101560378AReduce manufacturing costGood viscosity reduction effectDrilling compositionFiltrationPotassium hydroxide

The invention relates to an anti-sloughing diluted filtration reducing agent for drilling fluid and a preparation method thereof. The filtration reducing agent is prepared from the following raw materials by weight portion: 80 to 120 portions of substance containing humic acid, 30 to 80 portions of sodium metabisulfite, 300 to 500 portions of water, 10 to 30 portions of ammonium hydrolyzed polyacrylonitrile, 2 to 15 portions of cross linking agent, 30 to 50 portions of potassium hydroxide, 5 to 20 portions of complexing agent, 1 to 10 portions of urea and 10 to 20 portions of organic silicone resin. The preparation method comprises the following steps: weighting the water, the potassium hydroxide, lignite or peat or weathered coal and the sodium metabisulfite by weight portion, adding the materials into a stirred autoclave, sealing the stirred autoclave, raising the temperature, performing reaction and reducing the temperature; adding the ammonium hydrolyzed polyacrylonitrile, the cross linking agent, the complexing agent, the urea and the organic silicone resin by weight portion into the stirred autoclave after the temperature reduction, sealing the stirred autoclave, raising the temperature and stirring for reaction; and discharging, and performing spray drying on a product to obtain a finished product. The anti-sloughing diluted filtration reducing agent has good comprehensive performance, can prevent slough of mineshafts and reduce the filtration loss and viscosity of slurry, and is easy to realize safe production.

Owner:石家庄华莱鼎盛科技有限公司

Sulfonated acetone-formaldehyde high-efficiency water reducing agent modified by enzymatic hydrolysis lignin or by derivatives thereof, and preparation method thereof

The invention provides a sulfonated acetone-formaldehyde high-efficiency water reducing agent modified by enzymatic hydrolysis lignin or by derivatives thereof, and a preparation method thereof, raw materials comprise the enzymatic hydrolysis lignin or the derivatives thereof, acetone, aldehyde, sodium sulfite and sodium metabisulfite, a base catalyst and an acid regulator; the preparation steps comprise: mixing the sodium sulfite, the sodium metabisulfite with the water, heating at constant temperature and agitating, dropwise adding the acetone, adding the enzymatic hydrolysis lignin or the derivatives thereof, regulating pH value by the base catalyst, dropwise adding the aldehyde, continuous reacting for 3 hours, and adding the acid regulator to regulate the pH so as to result in product. The invention sufficiently utilizes reproducible biological resources, which not only solves the defect of low water reducing efficiency of the lignin-sulphonate water reducing agent extracted from papermaking 'black liquor' in the prior art, but also can replace partial petrochemical raw materials and reduce the production cost of the high-efficiency water reducing agent; the enzymatic hydrolysis lignin- or the derivatives thereof-modified high-efficiency water reducing agent has great use effect.

Owner:FUZHOU UNIV

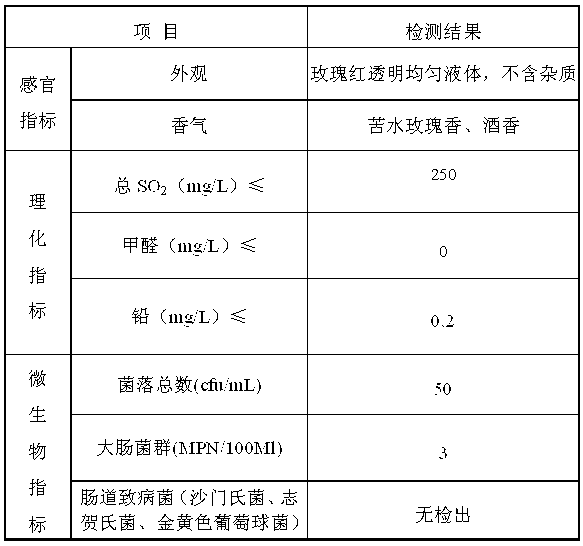

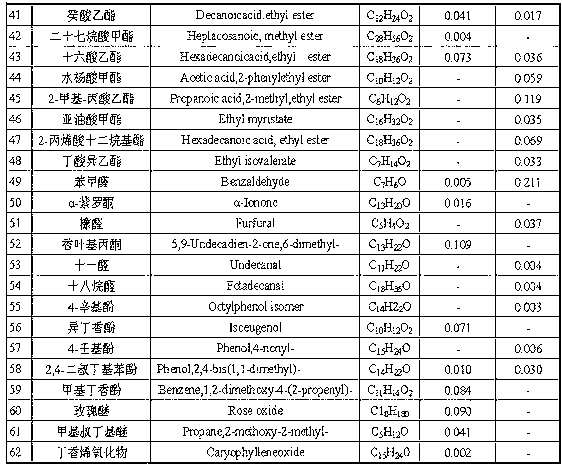

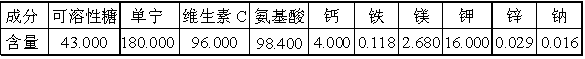

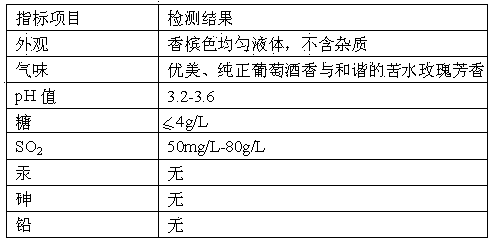

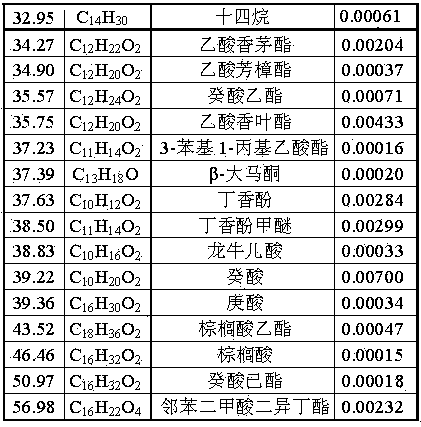

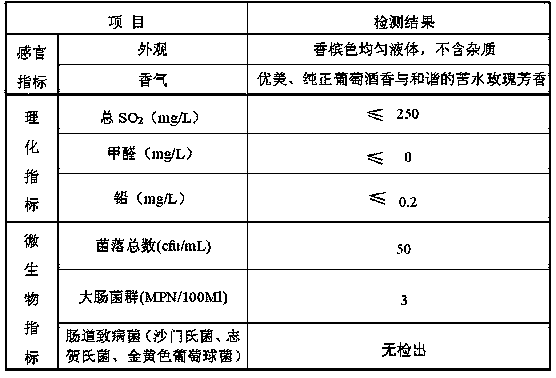

Fermented Kushui rose wine

InactiveCN102851178ASkin whiteningImproved abdominal pain after menstruationMicroorganism based processesAlcoholic beverage preparationBiotechnologyAlcohol content

The invention relates to a fermented Kushui rose wine. The preparation method of the fermented Kushui rose wine comprises the following steps: pulping Kushui roses in distilled water to obtain rose pulp; enabling the rose pulp to be sequentially subjected to acidity regulation, sodium metabisulfite sterilization, sugar content regulation, ingredient regulation (addition of yeast nutrients) and enzymolysis impregnation, and then adding Hongjianiang wine yeast to perform fermentation so as to obtain a fermented Kushui rose wine; aging and clarifying the fermented Kushui rose wine to obtain a clarified rose wine; filtering the clarified rose wine, regulating the sugar content to 45-60 g / L, and then adding sodium metabisulfite until the SO2 content is 10-15 mg / L; and finally, sterilizing according to the conventional method, and filling into a bottle to obtain the low-alcohol fermented Kushui rose wine of which the alcohol content is 5-9%(v / v). The fermented Kushui rose wine contains abundant nutrients, is rich in volatile aromatic components, has the effects of regulating the flow of qi, relieving the depressed liver, promoting blood circulation, dissipating blood stasis, regulating menstruation, alleviating pain, protecting against free radicals and resisting aging, and can remove fatigue and promote wound healing.

Owner:GANSU AGRI UNIV

Tannin based polymeric coagulants composition and method of use

InactiveUS20080149569A1Easy to produceEasy to useScale removal and water softeningSedimentation separationMethacrylateSodium metabisulfite

Composition and method of use for tannin based environmentally benign polymeric coagulants are disclosed. Tannin based coagulants are copolymers of naturally occurring tannins and a cationic monomer. One embodiment of the present invention provides for a composition of a tannin based polymeric coagulant which is comprised of N,N-(dimethylaminoethyl)methacrylate (MADAME) polymerized using t-butylhydroperoxide and sodium metabisulfite. The resulting polyMADAME is converted to hydrochloride and then blended / reacted in an aqueous medium with tannin to obtain a homogenous poly(MADAME)-Tannin composition.The method of use comprises adding an amount of the composition effective for the purpose of clarifying oily wastewater from food and beverage, steel, automotive, transportation, refinery, pharmaceutical, metals, paper and pulp, chemical processing and hydrocarbon processing industries.

Owner:BL TECH INC

Processing method of rose aromatized wine

The invention relates to a processing method of rose aromatized wine, which comprises the following steps: (1) grading Merlot grape fruit, sufficiently washing with water, crushing, squeezing, and adding sodium metabisulfite to obtain a grape mash; (2) adding Kushui roses, of which calyces are removed, into the grape mash, mixing, removing stems, and crushing to obtain a grape liquid; (3) adding activated pectinase into the grape liquid for impregnation for 36-48 hours, adding activated yeast, and fermenting at 22-27 DEG C by a conventional process; when the primary fermentation finishes after 10-12 days, separating new artesian wine, storing the wine in a closed fermentation tank, and carrying out secondary fermentation under the condition of not removing skin residues; when the secondary fermentation finishes after 60-90 days, removing wine legs, fully storing the wine in a tank for 2-3 months, adding chitosan and bentonite, and clarifying for 2.5 hours, thereby obtaining the clarified wine; and (4) filtering the clarified wine, adding sodium metabisulfite, sterilizing by a conventional process, and bottling. The invention has the advantages of simple production technique, low cost and low pollution.

Owner:GANSU AGRI UNIV

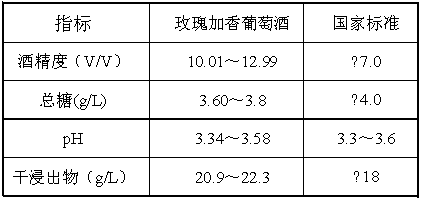

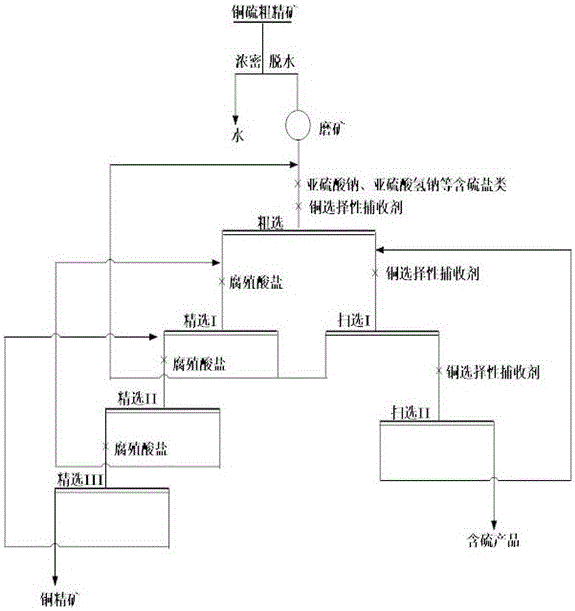

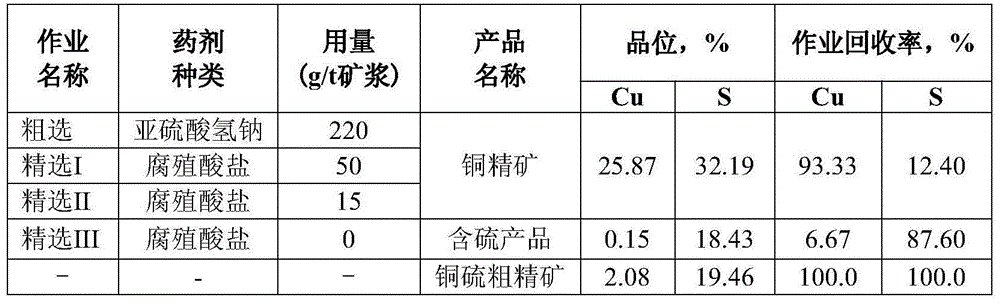

Copper and sulphur separation method for copper-sulphur ore

The invention provides a copper and sulphur separation method for copper-sulphur ore and relates to a method for separating copper from sulphur in copper-sulphur ore flotation rough concentrate. The copper and sulphur separation method for the copper-sulphur ore is characterized in that the steps of a treating process comprise that (1) ore grinding is conducted on copper-sulphur rough concentrate obtained through flotation; (2) after the ore grinding, a sulfur inhibitor selected from sodium sulfite, sodium metabisulfite, sodium bisulfate and sodium thiosulfate is added to the copper-sulphur rough concentrate, and a sulfur inhibition reaction is conducted; (3) a copper selective collector is added, and flotation is conducted; (4) a humate inhibitor is added to a flotation froth product; after an reaction with mixing is conducted, concentration is conducted; and (5) a humate inhibitor is added to a concentration froth product; after an reaction with mechanical mixing, concentration is conducted again, and copper concentrate separated from the sulphur is obtained. The copper and sulphur separation method for the copper-sulphur ore is simple in technology; lime and other highly alkaline inhibitors are not required to be added; required reagents are extensive in source and easy to prepare and add; the prepared reagents are good in flowability, easy to control, and not liable to block pipelines. The copper and sulphur separation method for the copper-sulphur ore is a novel copper and sulphur separation method.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Color-protecting antistaling agent for compound pickled vegetables and production method thereof

InactiveCN102578221AImprove the preservation effectExtended shelf lifeFruit and vegetables preservationDehydroacetic acidSodium acetate

The invention discloses a color-protecting antistaling agent for compound pickled vegetables and a production method thereof. The color-protecting antistaling agent is composed of dehydroacetic acid, sodium acetate, ascorbic acid, sodium erythorbate, sodium phytate, sodium citrate, citric acid, sodium metabisulfite and sodium chloride. The color-protecting antistaling agent is reasonable in components and convenient to manufacture, can effectively improve preserving performance of the pickled vegetables, prolongs guarantee period, is safe, and enables the preserving performance of the pickledvegetables to be improved by over one time compared with the preserving performance of an ordinary marketing product.

Owner:唐洪权

Phenol-urea-formaldhyde resin modified lignite filtrate loss reducer with high temperature resistance and salt tolerance, and its preparation method

InactiveCN102408882AImprove hydrophilic abilityStrong complexing abilityDrilling compositionSulfite saltTemperature resistance

The invention relates to a preparation method of a filtrate loss reducer used for drilling fluids. With lignite as the main material, the method first prepares a sulfonated phenol-urea-formaldhyde resin mixture, which is then reacted with an alkaline solution and lignite, thus obtaining a sulfonated phenol-urea-formaldhyde resin modified lignite filtrate loss reducer. The lignite filtrate loss reducer comprises the following reactants by weight: 10%-20% of lignite; 2%-4% of one of or a mixture of NaOH and KOH; 50%-60% of water; 2%-5.5% of phenol; 8%-15% of formaldehyde; 3%-7% of urea; 0.15%-2% of a hydrolyzed acrylonitrile sodium salt; 0.125%-0.5% of polyacrylamide; and 2%-7% of a sulfonating agent (one of or a mixture of sodium sulfite, sodium bisulfite, and sodium metabisulfite).

Owner:QILU UNIV OF TECH

Complex modified starch

InactiveCN101628945AHydrophilicHydrophilic hasFood preparationSodium metabisulfiteAdditive ingredient

The invention provides complex modified starch which is prepared from the following main ingredients in portion by weight: 100 portions of starch, 1-10 portions of 1-25% sodium hypochlorite, 1-10 portions of 1-25% sodium metabisulfite, 1-10 portions of acetyl oxide, 1-40 portions of 1-40% NaOH and 50-250 portions of water. In the reaction process of the complex modified starch, carboxyl and acetyl groups are introduced to the starch molecules, so the starch molecules have the characteristics of hydrophilicity and lipophilicity simultaneously, have the functions of emulsification and dispersion, and can emulsify water and grease brought in the production process of chocolate products to form a very stable structure.

Owner:聚祥(厦门)淀粉有限公司

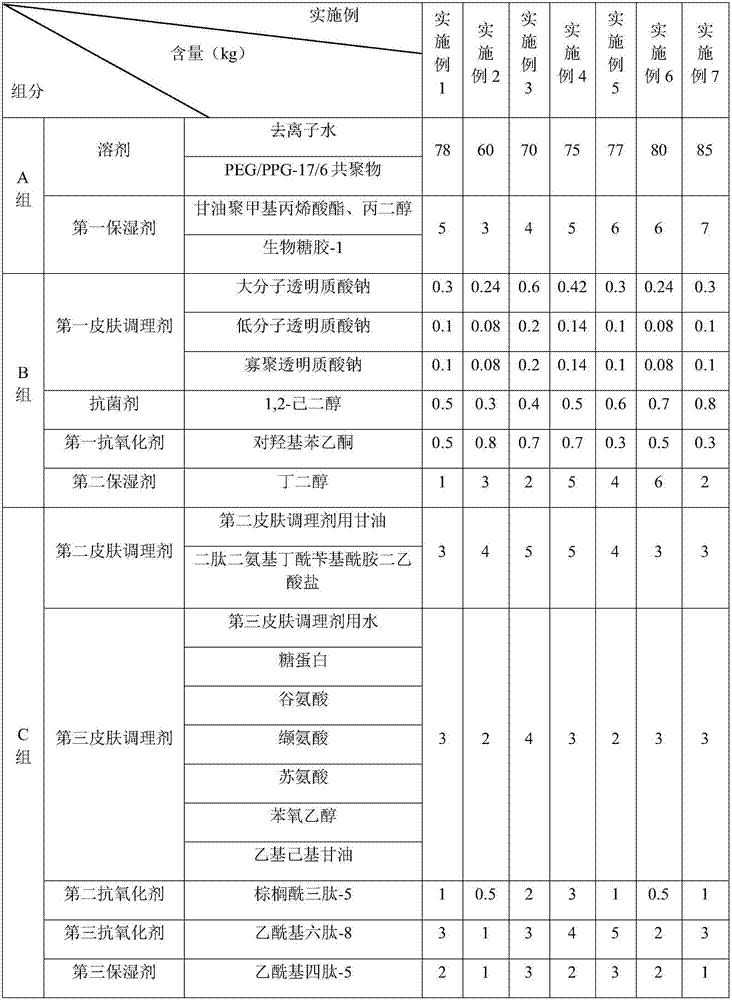

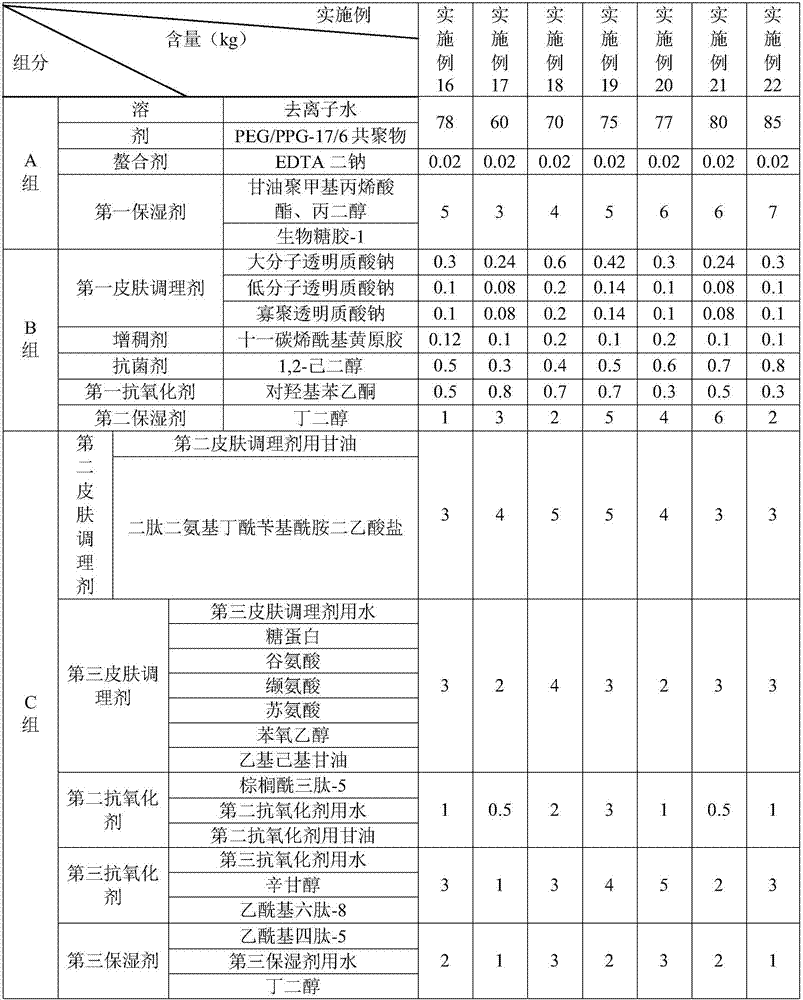

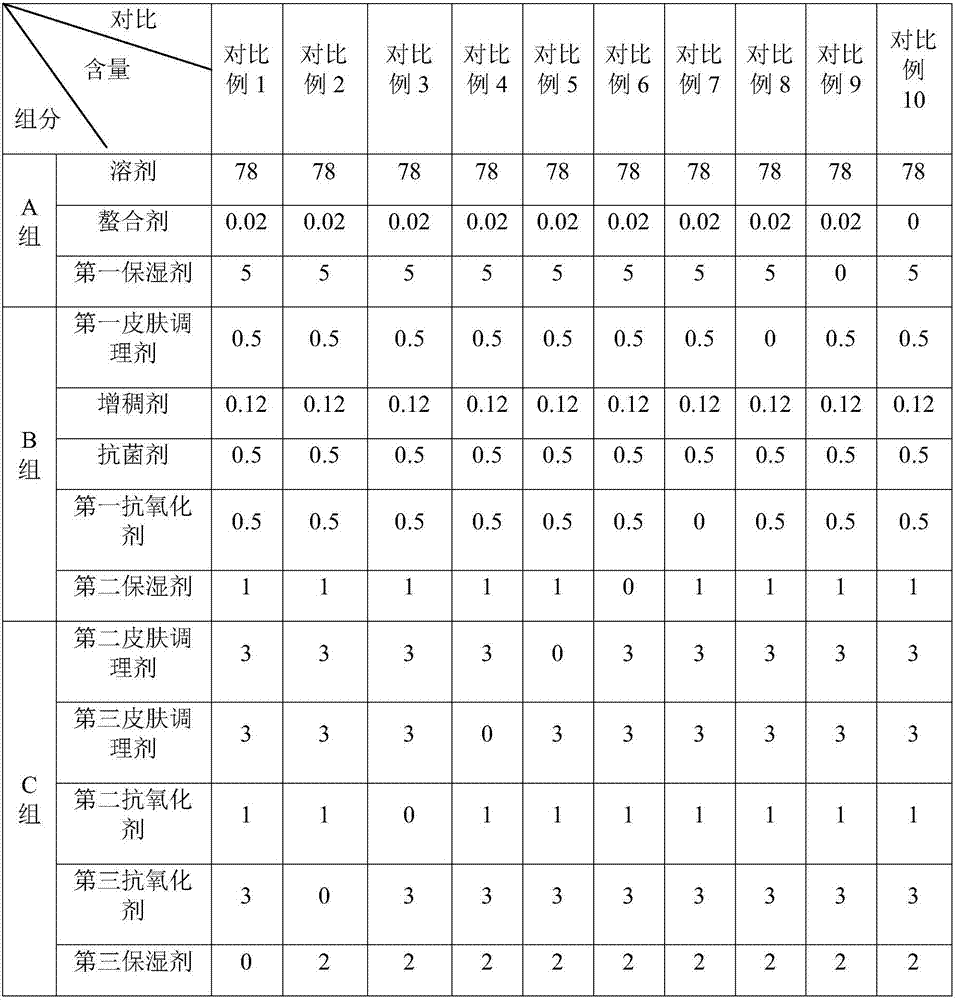

Hyaluronic acid anti-wrinkle essence

InactiveCN107951742ALimit contractionReduce wrinklesCosmetic preparationsToilet preparationsAntioxidantGlycerol

The invention discloses hyaluronic acid anti-wrinkle essence. The hyaluronic acid anti-wrinkle essence is prepared from a group A, a group B and a group C; the group A includes solvent and a first wetstorage agent; the group B includes a first skin conditioning agent, a first antioxidant agent and a second wet storage agent; the group C includes a second skin conditioning agent, a third skin conditioning agent, a second antioxidant agent, a third antioxidant agent and a third wet storage agent; the first wet storage agent is composed of multiple kinds of sodium hyaluronate; the second skin conditioning agent includes glycerol and dipeptide diaminobutyroyl benzylamide diacetate; the third skin conditioning agent includes water for the third skin conditioning agent, glycoprotein, multiple amino acids, phenoxyethanol, ethylhexylglycerin and sodium metabisulfite; the second antioxidant agent comprises palmitoyl tripeptide-5; the third antioxidant agent comprises acetyl hexapeptide-8; thethird wet storage agent includes acetyl tetrapeptide-4. The hyaluronic acid anti-wrinkle essence can improve skin metabolism, bring elasticity to the skin, reduce the shrinkage degree of the skin, andachieve good effects of removing wrinkles, moisturizing and nursing the skin and delaying aging.

Owner:JOTM DAILY CHEM HANGZHOU CO LTD

Chardonnay rosa stertata wine

Owner:GANSU AGRI UNIV

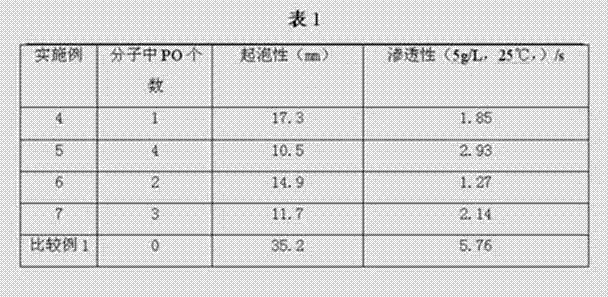

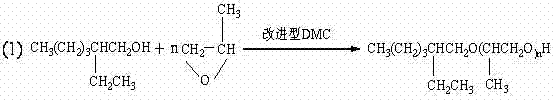

Preparation method of isooctanol polyoxypropylene ether sodium sulfosuccinate diester

InactiveCN102391158AHigh activityReduce dosageTransportation and packagingSulfonic acids salts preparationPtru catalystMethyl carbonate

The invention discloses a preparation method of isooctanol polyoxypropylene ether sodium sulfosuccinate diester. The method comprises the following steps of: adding epoxy propane into isooctanol serving as an initiator under the action of a modified DMC (Di Methyl Carbonate) catalyst for undergoing a condensation reaction to obtain isooctanol polyoxypropylene ether; undergoing an esterification reaction on the isooctanol polyoxypropylene ether and maleic anhydride under the catalytic action of a solid super acid S2O8<2-> / ZrO2 to obtain isooctanol polyoxypropylene ether sulfosuccinate diester; and undergoing a sulfonation reaction on the isooctanol polyoxypropylene ether sulfosuccinate diester and a sodium metabisulfite solution under the action of a phase transfer catalyst, and adding a NaOH aqueous solution till the pH of a reactant is 4-7 to obtain the isooctanol polyoxypropylene ether sodium sulfosuccinate diester. The preparation method has the advantages of clean, environmentally-friendly and simple production process, higher permeability and remarkable reduction in foams produced in the using process.

Owner:ZHEJIANG HECHENG CHEM

Method for making preserved cherry-tomatoes

The invention relates to a method for making preserved cherry-tomatoes. The method comprises the following steps of: selecting fruits, grading and piercing; protecting color, hardening, adding a mixed solution of 1.0 percent by submerging amount of calcium chloride and 0.03 percent by submerging amount of sodium metabisulfite and soaking for 3-5h; soaking in sugar: adding 100kg of cherry-tomatoes, 25-35kg of white granulated sugar and 0.03kg of potassium sorbate and standing for 40-50h; secondarily soaking in sugar: adding 0.5kg of citric acid, 0.3kg of sodium citrate and 10kg of white granulated sugar and soaking in sugar for 4-6 day; and drying at 60-65 DEG C for 10-12h and packaging into a finished product. The method avoids peeling or scalding in boiling water, keeps vitamins to the maximum extent and complete and attractive single preserved tomato with sugar dipped, is rich in nutrients and has agreeable taste, simplified production process and decreased production cost.

Owner:CHUXIONG YUANMOUREN FOOD

Nutritious plumule biscuit and its production process

InactiveCN1973634AHigh nutritional valuePromote peristalsisDough treatmentBakery productsFermentationChemistry

The nutritious plumule biscuit and its production process belong to the field of food producing technology. The nutritious plumule biscuit is produced with wheat plumule powder, flour, starch, sugar powder, ammonium bicarbonate, water, palm oil and compound enzyme preparation, and through mixing the materials, fermentation and roasting. The present invention replaces enzyme preparation for food level sodium metabisulfite, and adopts low temperature roasting, laminating and short fermentation time. The nutritious plumule biscuit has less damping, less breaking and long shelf life.

Owner:SHANDONG ZHENGHANG FOODSTUFF

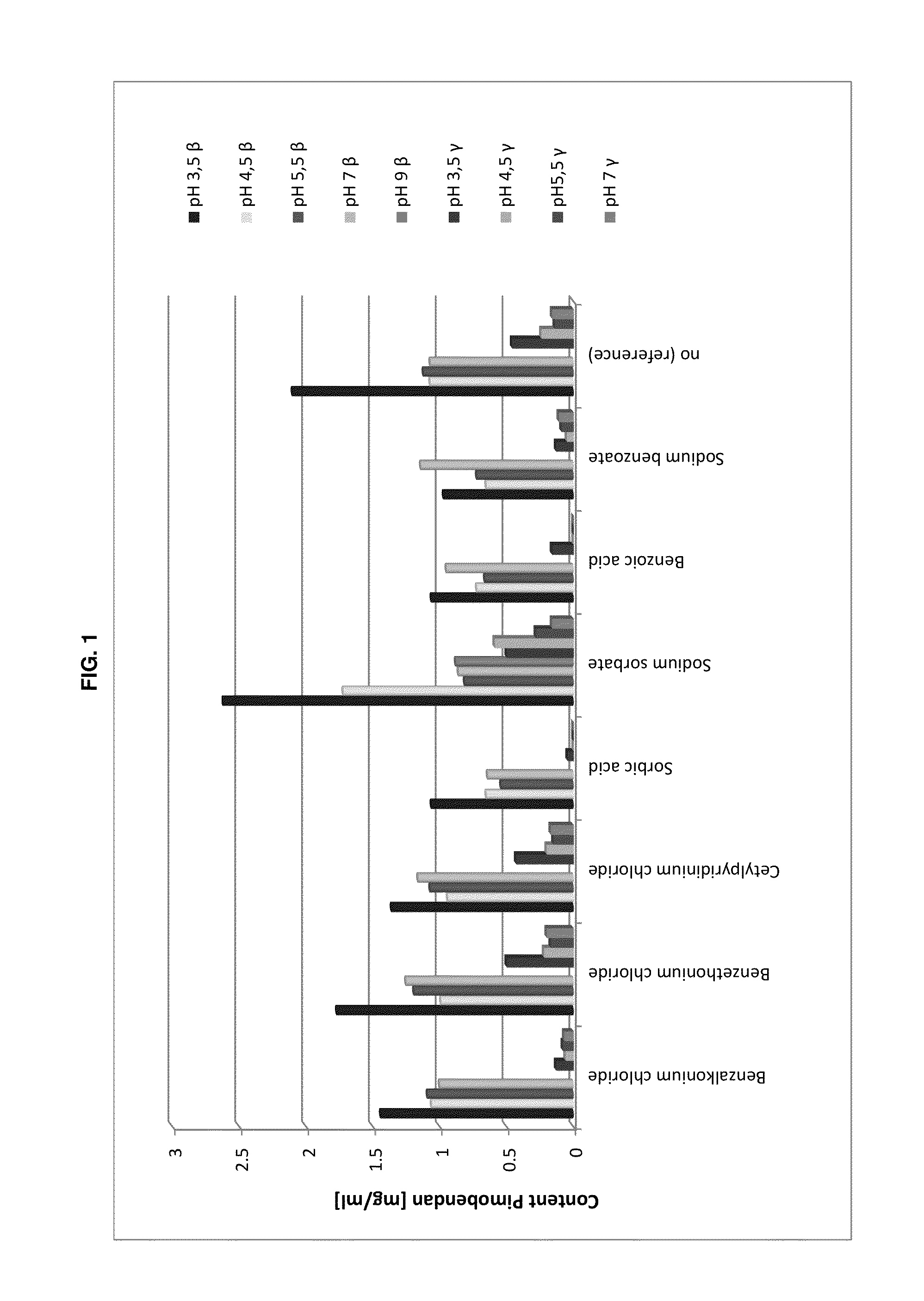

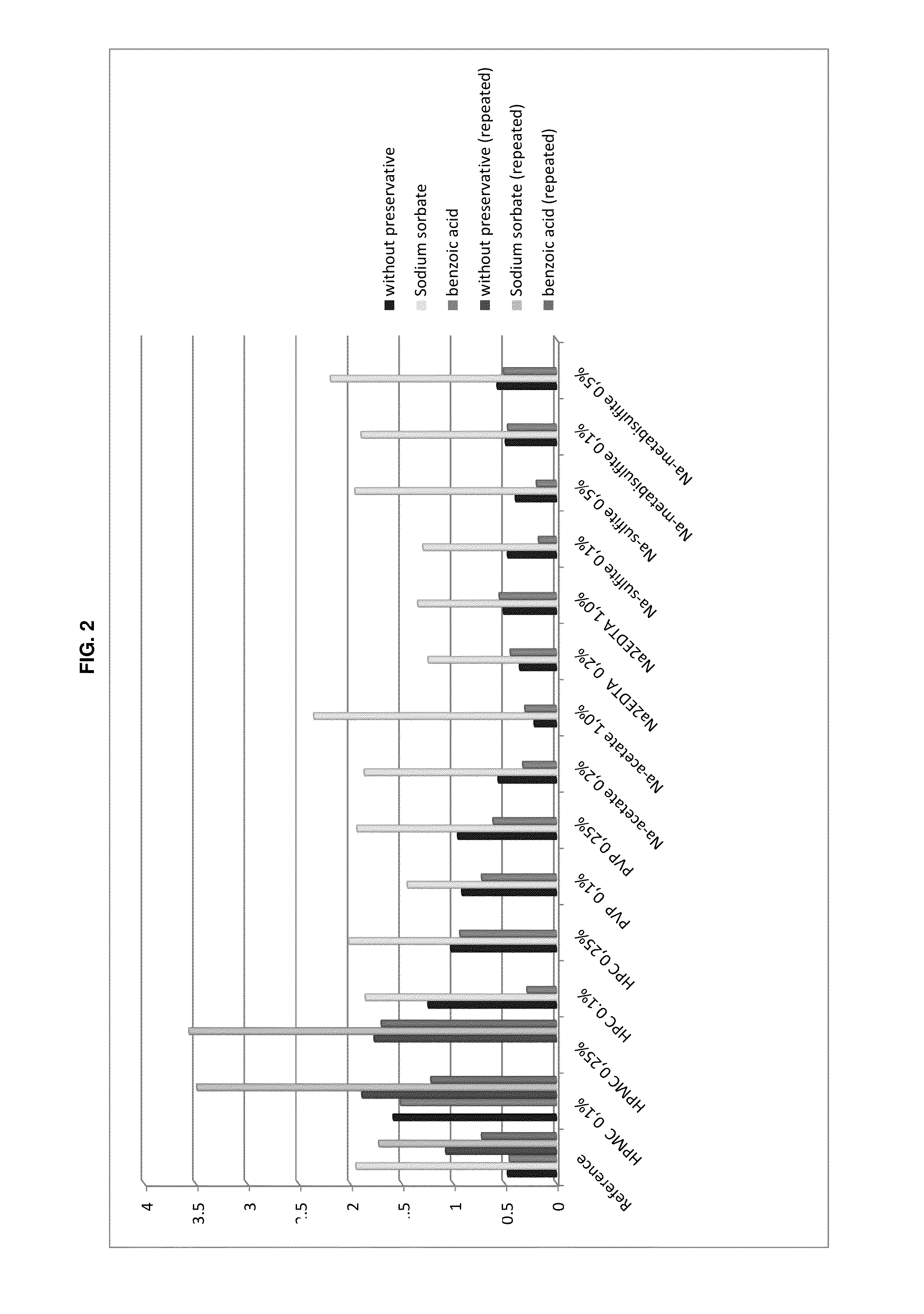

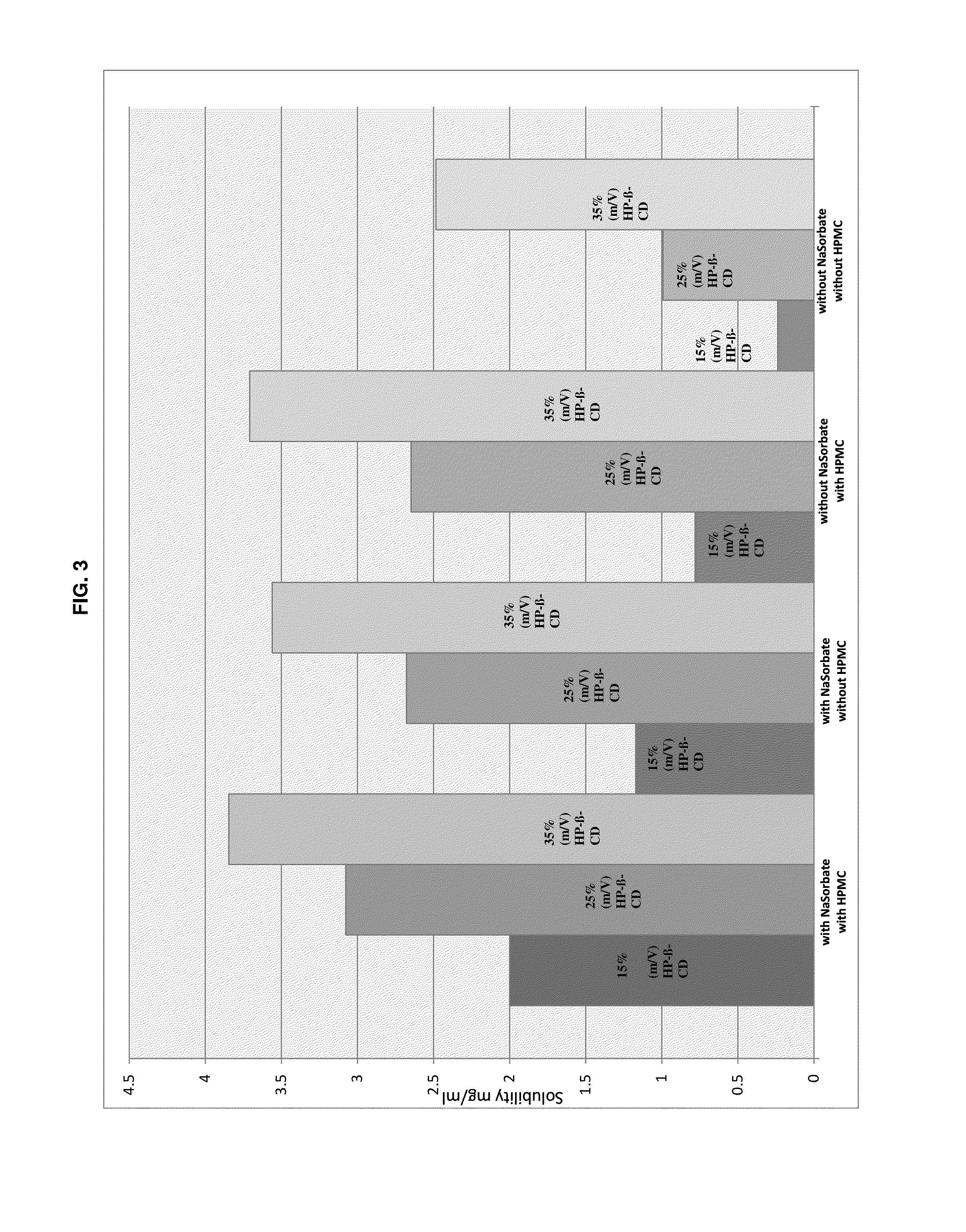

Preserved etherified cyclodextrin derivatives containing liquid aqueous pharmaceutical composition

ActiveUS20150025082A1Inhibit microbial growthRetaining its effectivenessAntibacterial agentsNervous disorderSodium acetrizoateSodium acetate

The present invention is directed to a preserved liquid aqueous pharmaceutical composition comprising one or more etherified cyclodextrin derivatives; one or more water-soluble preservatives; preferably selected from the group consisting of sorbic acid or salts thereof, preferably sodium sorbate, potassium sorbate, calcium sorbate; benzoic acid or salts thereof, preferably sodium benzoate; benzalkonium chloride; benzethonium chloride; cetylpyridinium chloride; sodium metabisulfite; sodium acetate; parabenes and salts thereof, preferably methylparabene, ethylparabene, propylparabene, butylparabene, butylparabene sodium; or combinations thereof; and at least one pharmaceutically active compound which is poorly water-soluble, very poorly water-soluble or water-insoluble. The liquid aqueous pharmaceutical composition provides an acceptable solubility of the pharmaceutically active compound, such as pimobendan, in aqueous solution whereby the water-soluble preservatives retain their effectiveness in the presence of the etherified cyclodextrin derivatives allowing the use in an oral administration form.

Owner:BOEHRINGER LNGELHEIM VETMEDICA GMBH

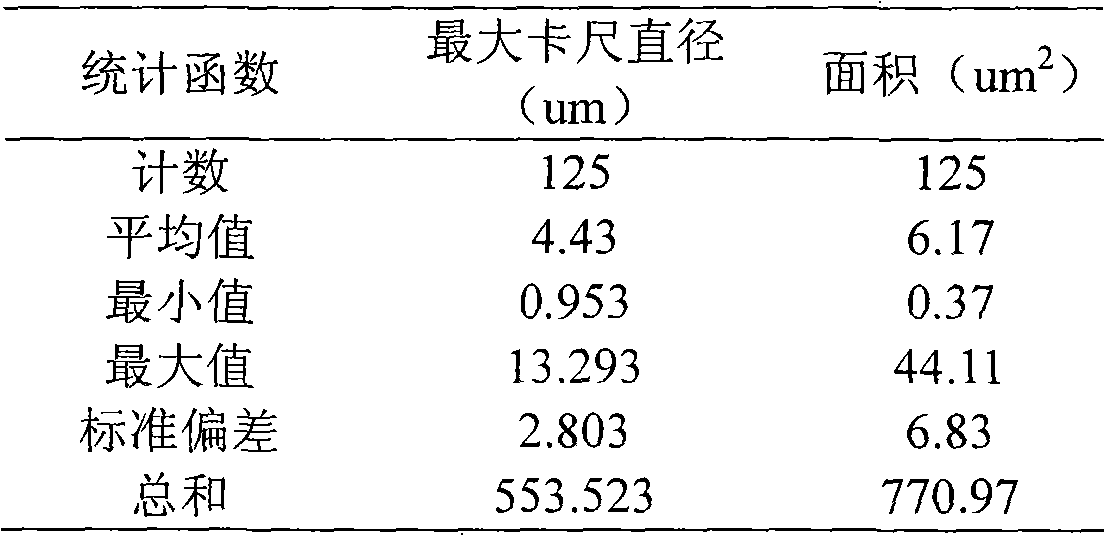

Preparation method for nonionic oxidized polyethylene wax emulsion using single emulsifier

The invention belongs to the field of chemical industry, and specifically relates to a preparation method for a nonionic oxidized polyethylene wax emulsion using a single emulsifier. The preparation method provided by the invention comprises the following steps of: adding oxidized polyethylene wax (AC-629), a nonionic emulsifier, an emulsification aid, KOH, sodium metabisulfite and deionized water according to a certain weight ratio to a high-pressure reaction kettle, followed by covering and sealing; and emulsifying high-melting-point AC-629 wax at high temperature and high pressure through a one-step method to obtain a microemulsion, wherein the emulsifying temperature is 130-150 DEG C, the emulsifying pressure is 1.5-17.0 MPa, and the amount of the nonionic emulsifier is 18-26% of that of the AC-629 wax; the average particle size of a product is controlled at 35-200 nm through changing emulsifying conditions; and the solid content in the product is controlled at 30-45% through changing the use level of the AC-629 wax. The preparation method provided by the invention is simple in process, only uses one nonionic emulsifier, and lowers the production cost of OPE (oxidized polyethylene) emulsion; and the obtained OPE emulsion is pollution-free and environmentally-friendly.

Owner:SHAOGUAN LIANBANG ENVIRONMENTALLY FRIENDLY NEW MATERIALS CO LTD

Method for extracting fructus cannabis oligopeptide from fructus cannabis cake

InactiveCN106011207AHigh purityImprove separation efficiencyPeptide preparation methodsFermentationCannabisFreeze-drying

The invention provides a method for extracting fructus cannabis oligopeptide from a fructus cannabis cake. The method comprises the following steps: collecting the fructus cannabis cake with the oil content of lower than 1%, adding water, regulating the pH value to 9.0, adding sodium metabisulfite, carrying out solid-liquid separation, and collecting the liquid phase; adding a HCl solution into the liquid phase, regulating the pH value to 3.8-4.3, standing, carrying out secondary solid-liquid separation, and collecting the precipitate; adding water, heating to 40-55 DEG C, regulating the pH value to 7.0-9.0, adding a compound protease, carrying out enzymolysis for 3-6 hours, carrying out centrifugal filtration, and collecting the clear solution which is the fructus cannabis oligopeptide solution; and carrying out electrodialysis, concentration and freeze-drying to obtain the fructus cannabis oligopeptide powder. The fructus cannabis cake subjected to press deoiling is used as the raw material, the isoelectric point principle is combined to precipitate the protein, and the compound protease enzymolysis and freeze-drying are performed to obtain the fructus cannabis oligopeptide. The whole process utilizes the pure physical technique, and no chemical component is added; and thus, the method has the advantages of low cost and no environment pollution.

Owner:山西汉麻生物科技有限公司

Quantitative determination method of martensite in dual phase steel

InactiveCN101576504AImprove accuracyClear outlinePreparing sample for investigationMaterial analysis by optical meansBasic researchSoftware

The invention discloses a quantitative determination method of martensite in dual phase steel. The steps are as follows: preparing sodium metabisulfite and water into an aqueous solution A with the mass percentage of 1.5-3 percent; preparing trinitrophenol and alcohol into a solution B with the mass percentage of 2-3.8 percent; mixing and uniformly stirring the aqueous solution A and the solution B according to the volume rate of 1:1; putting a dual phase steel sample in the prepared etching agent and taking the sample out after the surface of the sample presents blue, with the etching ambient temperature being 10-30 DEG C; observing under a metaloscope provided with a color camera; and using metallographic quantitative analysis software to determine. The method is characterized in that the texture of each phase in the dual phase steel presents different colors, clear outline and distinct arrangement, and is easy for identification; and qualitative and quantitative analysis can be effectively conducted on the texture of each phase, with high accuracy of the quantitative result. The method plays an important part in production inspection and fundamental researches.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Antioxidant willow-rattan softening agent and preparation method thereof

ActiveCN103692517AFast softening speedSoften evenlyWood treatment detailsWood impregnation detailsAntioxidantRaw material

The invention discloses an antioxidant willow-rattan softening agent which is prepared from the following raw materials in parts by weight: 6-8 parts of citric acid, 3-4 parts of sodium metabisulfite, 3-5 parts of alkanolamide, 4-6 parts of ethylenediamine tetraacetic acid, 7-10 parts of eupatorium, 3-4 parts of wild chrysanthemum flower, 2-3 parts of scutellaria baicalensis, 4-5 parts of clove, 2-3 parts of safflower carthamus, 5-6 parts of radix sophorae flavescentis, 3-4 parts of povidone-iodine, 3-4 parts of an assistant and 100 parts of water. According to the antioxidant willow-rattan softening agent, the citric acid and the sodium metabisulfite are used, thus the antioxidant willow-rattan softening agent is high in softening speed, and capable of resisting oxidization; through using the ethylenediamine tetraacetic acid, the antioxidant willow-rattan softening agent is more uniform in softening and good in flexibility; through using the alkanolamide, rattans are smooth in surface, soft in hand feel, and the weaving efficiency can be increased; by using the Chinese herbal medicines such as the scutellaria baicalensis and the povidone-iodine, the antioxidant willow-rattan softening agent is capable of preventing from being mildewed and damaged by worms, emits fragrance, and is capable of refreshing.

Owner:FUNAN YONGXING ARTS & CRAFTS

Method for preparing 1,3-propane sultone

The invention provides a method for preparing 1,3-propane sultone (PS). The method comprises the following steps: dripping allyl chloride into a certain quantity of a sodium metabisulfite aqueous solution to prepare sodium allyl sulfonate; carrying out reaction between sodium allyl sulfonate and sulfuric acid under the existence of a catalyst; carrying out hydrolysis under an alkali condition; carrying out acidation to prepare 3-hydroxypropanesulfonic acid; conducting cyclodehydration under the existence of an inert dehydrating agent to prepare 1,3-propane sultone. The method has the advantages that allyl chloride which is cheap is taken as a raw material; the target product with relatively high yield is prepared according to the four steps of substitution, addition reaction, hydrolysis and cyclization; the reaction condition is mild; the suitability for mass production is realized.

Owner:RONGCHENG QINGMU CHEM MATERIALS

Grinding aid for removing chromium from liquid cement and preparation method of grinding aid

The invention discloses a grinding aid for removing chromium from liquid cement and a preparation method of the grinding aid, and belongs to the technical field of cement grinding. The grinding aid for removing chromium from liquid cement is prepared from the following raw materials in parts by weight: 5-20 parts of a grinding aid dispersant, 30-60 parts of a reducer, 20-40 parts of water and 0.5-2 parts of an anti-crystallization agent. According to the invention, sodium metabisulfite or sodium thiosulfate is used as a chromium removal raw material, which can reduce the hexavalent chromium content of the cement from 10-20 ppm to 10 ppm or less than10 ppm. In addition, the anti-crystallization agent used effectively avoids crystallization of the reducer in the solution to ensure the efficiency of removing chromium. The grinding aid dispersant is added in the grinding aid, so that not only are rapid dispersion and rapid reaction of the chromium reducing components facilitated, the chromium removal effect is ensured, but also the cement grinding efficiency and the cement strength are improved, and functions of a product are enriched.

Owner:SHANDONG HONGYI TECH

Preparation method for stable iodinated vegetable oil ethyl ester

The invention relates to a preparation method for stable iodinated vegetable oil ethyl ester. The method mainly includes the following steps: performing addiction reaction between vegetable oil and hydrogen iodide gas to generate iodinated vegetable oil; removing unstable iodine incorporated in the iodinated vegetable oil by adding hydrogen peroxide; eliminating removed iodine by using sodium metabisulfite solution to obtain stable iodinated vegetable oil; and performing ester exchange reaction between the stable iodinated vegetable oil and ethanol under the function of basic catalyst to produce the stable iodinated vegetable oil ethyl ester. The iodinated vegetable oil ethyl prepared by using the method has the characteristics of small viscosity and environmental-friendly technology.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Honey mead and honey pollen health wine making method

InactiveCN1880430AImprove immunityGreat tasteAlcoholic beverage preparationBiotechnologyRed yeast rice

The invention discloses a brewing method of honey wine and honey pollen hygienic wine, which comprises the following steps: filtering fine-selected liquefied honey; blending honey and purified water into honey water liquid; adding sodium metabisulfite and yeast emulsion to proceed alcohol ferment; filtering; sealing the brewed honey wine to product the product; blending honey pollen, red date, lucid ganoderma powder, purified water; immersing; boiling; blending red yeast rice; fermenting to obtain honey pollen nutrient solution; brewing honey pollen nutrient solution, good-quality honey and purified water to generate honey pollen hygienic wine.

Owner:孙士尧

Copper oxide and copper sulfide ore flotation agent and preparation method thereof

Copper oxide and copper sulfide ore flotation agent is made with, by weight, 15-19 parts of gutter oil, 3-5 parts of silica sol, 5-7 parts of sodium naphthenate, 4-5 parts of urea, 2-3 parts of sodium carbonate, 5-7 parts of chitosan, 6-9 parts of mimosa extract, 3-4 parts of sodium metabisulfite, 2-4 parts of fatty alcohol-polyoxyethylene ether, 20-25 parts of black powder, and 4-5 parts of activator. The floatation agent with the gutter oil remains foamy, and the cost is reduced; through the use of the chitosan and silica sol, flocculation is effective and yield is increased; the flotation agent is capable of well collecting copper, copper yield is high, the flotation agent is well selective, has good inhibitory action against other ores, and copper grade is high. The activator contains the components such as jade nanopowder, is capable of stably dispersing and has good permeability and activity, the activation effect lasts long, and the yield and grade of copper is increased. The flotation agent is low in environmental pollution.

Owner:安徽冠华稀贵金属集团有限公司

Preparation method of waffle cake and product

The invention relates to a method for preparing an egg and milk cake biscuit and a product thereof. The technical problem to be solved is to provide the method for preparing the egg and milk cake biscuit with a taste between the common biscuits and the cakes. The technical proposal is that the method for preparing the egg and milk cake biscuit includes the following steps: (1) preparing the sirup by adding 100 parts of sugar to 65-70 parts of water, boiling and adding 0.18-0.22 parts of alum; (2) preparing the ingredient including 38-40 parts of the sirup, 1.30-1.60 parts of ammonium acid carbonate, 0.08-0.12 parts of sodium metabisulfite, 0.4-0.60 parts of saleratus and 2.00-2.50 parts of egg; (3) kneading the dough, pouring the ingredient prepared in step (2) into 50 parts of high protein flour; (4) preparing the biscuit. The method has the advantages that no antiseptic or lipid is added in the preparation process, the egg and milk cake biscuit is not only as chewy as the biscuit but also as soft as the cake, and has storage endurance.

Owner:范树丛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com