Anti-salt type thicking oil reducing viscosity agent and preparation process thereof

A heavy oil viscosity reducer, salt-type technology, applied in earth-moving drilling, fluid production, wellbore/well components, etc., can solve problems such as non-reporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

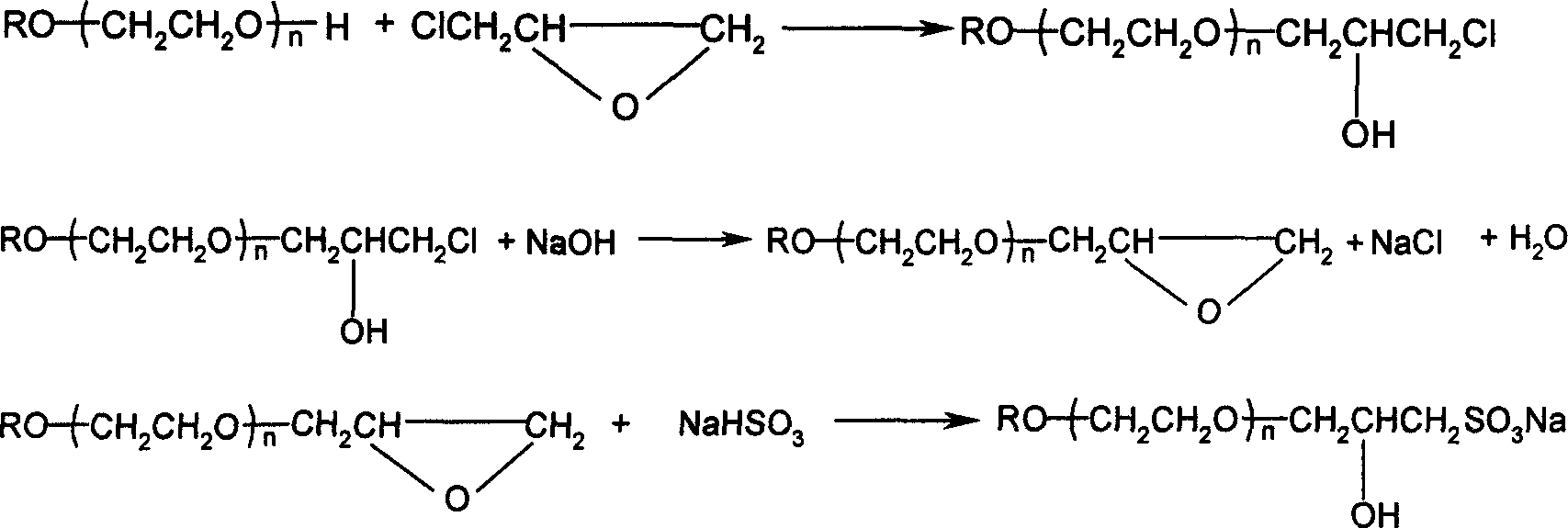

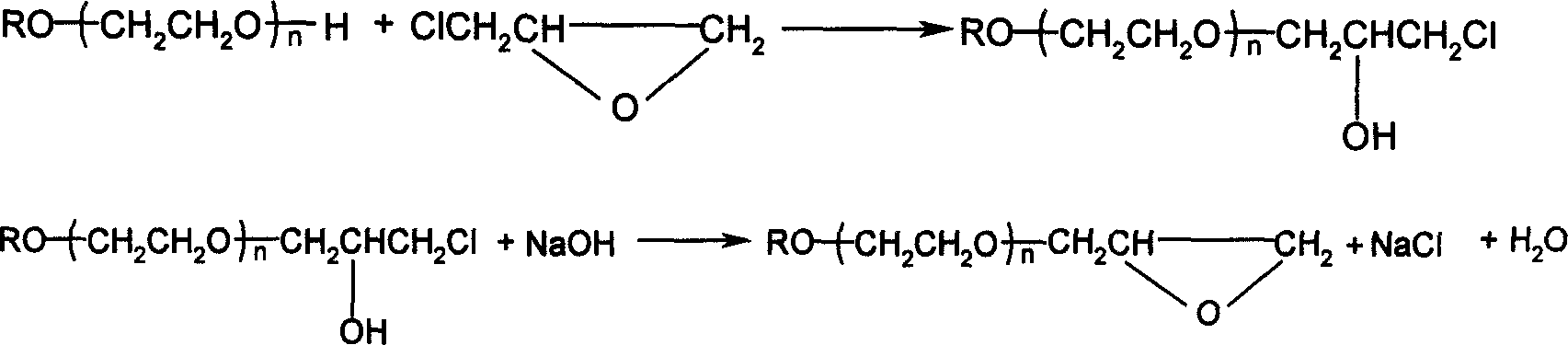

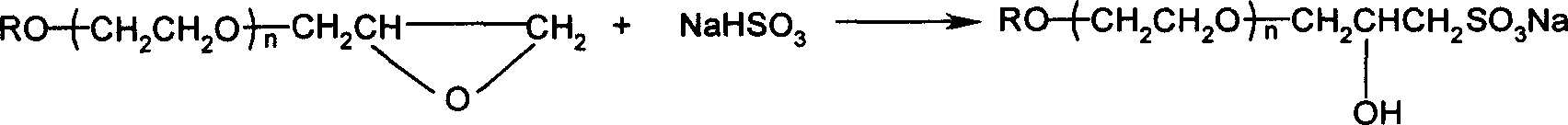

[0023] Mainly explain the preparation of polyoxyethylene nonylphenol ether hydroxypropanesulfonate sodium-15.

[0024] Add 0.1 mol of polyoxyethylene nonylphenol ether-15 to the three-necked flask, and then add 1.2 g of tin tetrachloride, heat the oil bath to 100°C, and drop 0.15 mol of epichlorohydrin from the funnel while stirring. After dripping the epichlorohydrin, react for 0.5 hour to obtain the intermediate product polyoxyethylene ether chlorohydroxypropane-15. Add 0.11 mol of sodium hydroxide to the above product and react at 70°C for 0.5 hour to obtain the intermediate product polyoxyethylene ether propylene oxide-15. Finally, 0.2 mol of sodium bisulfite and 0.1 mol of sodium sulfite were added, and the temperature was raised to 140° C. for 4 hours to obtain polyoxyethylene nonylphenol ether hydroxypropanesulfonate sodium-15 with a total yield of 65%. Add 3 times the mass of water to make thick oil viscosity reducer 1.

Embodiment 2

[0026] Use polyoxyethylene nonylphenol ether-8 as a raw material, add 0.1mol polyoxyethylene nonylphenol ether-8 into a three-necked flask, then add 1.2g of tin tetrachloride, heat the oil bath to 100°C, and while stirring Add 0.15mol epichlorohydrin dropwise into the funnel. After dripping the epichlorohydrin, react for 0.5 hour to obtain the intermediate product polyoxyethylene nonylphenol ether chlorohydroxypropane-8. Add 0.11mol sodium hydroxide to the above product, and react at 70°C for 0.5 hour to obtain the intermediate product polyoxyethylene nonylphenol ether propylene oxide-8. Finally, 0.2 mol of sodium bisulfite and 0.1 mol of sodium sulfite were added, and the temperature was raised to 140° C. for 4 hours to synthesize polyoxyethylene nonylphenol ether hydroxypropanesulfonate-8, with a total yield of 67%. Add 3 times the mass of water to make thick oil viscosity reducer 2.

[0027] Features of the present invention:

[0028] By selecting polyoxyethylene ether n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com