Preparation method for stable iodinated vegetable oil ethyl ester

A technology for vegetable oil and oil ethyl ester, which is applied in the field of preparation of iodinated vegetable oil ethyl ester, can solve the problems of unsuitability for industrial production, long time, and multiple industrial waste water, and achieves improved production efficiency, good stability, and less industrial waste water. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

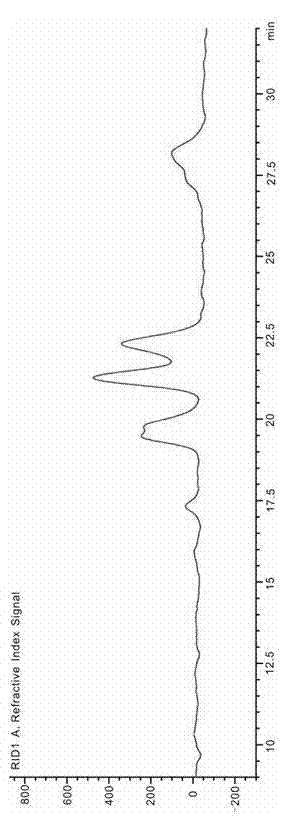

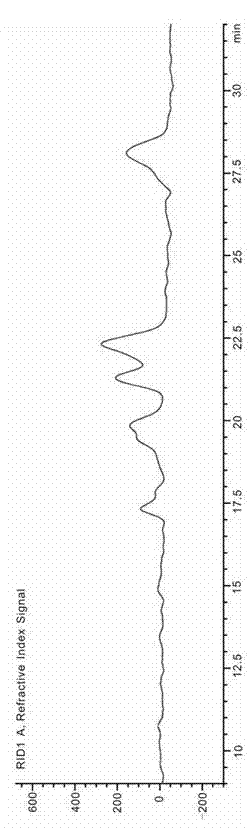

Image

Examples

Embodiment 1

[0019] Embodiment 1 (synthesis of stable iodinated poppy seed oil ethyl ester):

[0020] 1). Synthesis of stabilized iodinated poppy seed oil,

[0021] At 25°C, add 100g of iodine and 15g of red phosphorus into the reactor, slowly drop into 20mL (that is, 20g) of water, and generate hydrogen iodide gas in the process, and pass the generated hydrogen iodide gas into a tank containing 100g In the reactor of poppy seed oil, the reaction time is 36 hours to obtain crude iodized poppy seed oil, wash 6 times with ethanol equivalent to 1 / 2 volume of crude iodized poppy seed oil, remove free iodine, and then use Concentration is 0.2mol / L sodium metabisulfite solution washes until its color and luster no longer becomes lighter, obtains iodinated poppy seed oil 143g. At 30°C, add 200ml of 5% aqueous hydrogen peroxide solution to the iodized poppy seed oil prepared above to remove iodine that is unstable in combination, keep stirring at 30°C for 5 hours, and then use a concentration of...

Embodiment 2

[0025] Embodiment 2 (synthesis of iodized peanut oil ethyl ester):

[0026] 1). Synthesis of stable iodinated peanut oil,

[0027] At 0°C, first mix 15g of red phosphorus with 20mL (20g) of water to obtain a suspension containing red phosphorus powder and water, add 100g of iodine into the reactor, and then slowly drop into the suspension containing red phosphorus powder and water Liquid, produce hydrogen iodide gas in this process, the hydrogen iodide gas that will produce is passed in the reactor that 100g peanut oil is housed, and the reaction time is 16 hours, obtains crude iodized peanut oil, with the equivalent crude iodine The ethanol washing of 1 / 8 volume of the peanut oil was washed 10 times to remove free iodine, and then washed with a 0.2mol / L sodium metabisulfite solution until its color was no longer lightened to obtain 148g of iodized peanut oil. At 25°C, add 100ml of 13% aqueous hydrogen peroxide solution to the iodized peanut oil prepared above to remove iodi...

Embodiment 3

[0031] A preparation method of stable iodized vegetable oil ethyl ester, it comprises the steps:

[0032] 1) Synthesis of stable iodized vegetable oil:

[0033]The mass ratio of vegetable oil, iodine, red phosphorus and water is 100g: 100g: 15g: 20g to select vegetable oil, iodine, red phosphorus and water, and the vegetable oil is sunflower oil, linseed oil and corn oil, sunflower oil, linseed The quality of oil and corn oil each accounts for 1 / 3; at 20°C, add 100g of iodine and 15g of red phosphorus into the reactor, slowly drop into 20mL (ie 20g) of water, during this process hydrogen iodide gas is generated, and the The hydrogen iodide gas that produces passes in a reactor that 100g vegetable oil is housed, and the reaction time is 24 hours, obtains crude iodized vegetable oil, washes 7 times with the ethanol that is equivalent to crude iodized vegetable oil 1 / 2 volume, removes The free iodine is then washed with a 0.5mol / L sodium metabisulfite solution until its color is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com