Grinding aid for removing chromium from liquid cement and preparation method of grinding aid

A grinding aid and cement technology, applied in the field of cement grinding, can solve the problems of unusable product hardening, sensitive skin, inconvenient use, etc., to avoid crystallization, ensure the effect of removing chromium, and improve the grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

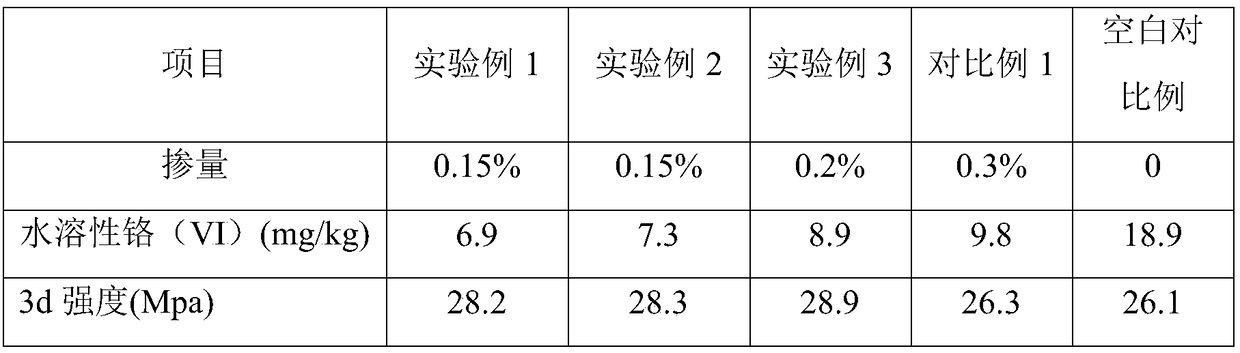

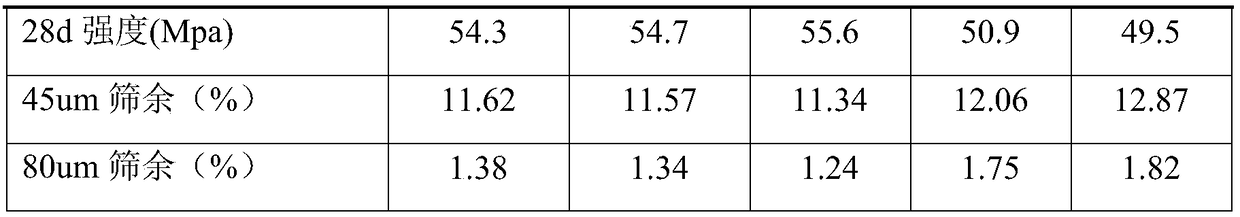

Examples

Embodiment 1

[0030] A liquid cement chromium removal grinding aid is prepared from the following raw materials in parts by weight: 5 parts of grinding aid dispersant, 30 parts of reducing agent, 20 parts of water, and 0.5 part of anti-crystallization agent; the grinding aid dispersant is Diethanol monoisopropanol, purity is 85%; Described reducing agent is sodium thiosulfate; Described anti-crystallization agent is made through the following steps:

[0031] (1) Prepare A solution: weigh 5 parts of acrylic acid, 0.2 parts of thiopropionic acid and 11 parts of deionized water, stir and dissolve to make A solution;

[0032] (2) Prepare B solution: pulverize the diaobai block, weigh 0.3 parts, dissolve in 25 parts of deionized water, stir and dissolve to make B solution;

[0033] (3) Add 40 parts of deionized water into the reaction kettle, then stir and add 70 parts of methallyl polyoxyethylene ether, heat to 30°C, and control it to a constant temperature of 30°C. After all of it is dissolved...

Embodiment 2

[0044] A liquid cement chromium removal grinding aid is prepared from the following raw materials in parts by weight: 10 parts of a grinding aid dispersant, 45 parts of a reducing agent, 30 parts of water, and 1 part of an anti-crystallization agent; the grinding aid dispersant is Triethanolamine; Described reducing agent is sodium thiosulfate; Described anti-crystallization agent is made through the following steps:

[0045] (1) Prepare A solution: weigh 7 parts of acrylic acid, 0.3 part of thiopropionic acid and 12 parts of deionized water, stir and dissolve to make A solution;

[0046] (2) Prepare B solution: pulverize the diaobai block, weigh 0.4 parts, dissolve in 27 parts of deionized water, stir and dissolve to make B solution;

[0047] (3) Add 43 parts of deionized water into the reaction kettle, then stir and add 75 parts of methallyl polyoxyethylene ether, heat to 30°C, and control it to a constant temperature of 30°C. After all of them are dissolved, add 0.5 parts o...

Embodiment 3

[0059] A liquid cement chromium removal grinding aid is prepared from the following raw materials in parts by weight: 20 parts of grinding aid dispersant, 60 parts of reducing agent, 40 parts of water, 2 parts of anti-crystallization agent; the grinding aid dispersant is Glycerin; The reducing agent is sodium pyrosulfite; The anti-crystallization agent is made through the following steps:

[0060] (1) Prepare A solution: weigh 10 parts of acrylic acid, 0.4 part of thiopropionic acid and 13 parts of deionized water, stir and dissolve to make A solution;

[0061] (2) Prepare B solution: pulverize the diaobai block, weigh 0.5 parts, dissolve in 30 parts of deionized water, stir and dissolve to make B solution;

[0062] (3) Add 45 parts of deionized water into the reaction kettle, then stir and add 80 parts of methallyl polyoxyethylene ether, heat to 30°C, and control it to a constant temperature of 30°C. After all of it is dissolved, add 0.6 parts of Hydrogen peroxide, stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com