Quantitative determination method of martensite in dual phase steel

A quantitative measurement, dual-phase steel technology, applied in the field of detection and analysis, can solve the problems of inability to analyze the state of martensite, inability to quantitatively analyze geometric dimensions, increase test costs, etc., and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Quantitative determination method of martensite in duplex steel, its steps:

[0029] 1) Sodium metabisulfite and water are configured into an aqueous solution A with a concentration of 1.5% by mass;

[0030] 2) configuring picric acid and alcohol into a solution B with a concentration of 2% by mass;

[0031] 3) Prepare etchant: mix 1.5% aqueous solution A and 2% solution B at a volume ratio of 1:1 and stir evenly;

[0032] 4) Put the dual-phase steel sample into the etchant configured above, take out the sample after the surface of the dual-phase steel sample turns blue, and control the etching environment temperature at 10-20°C;

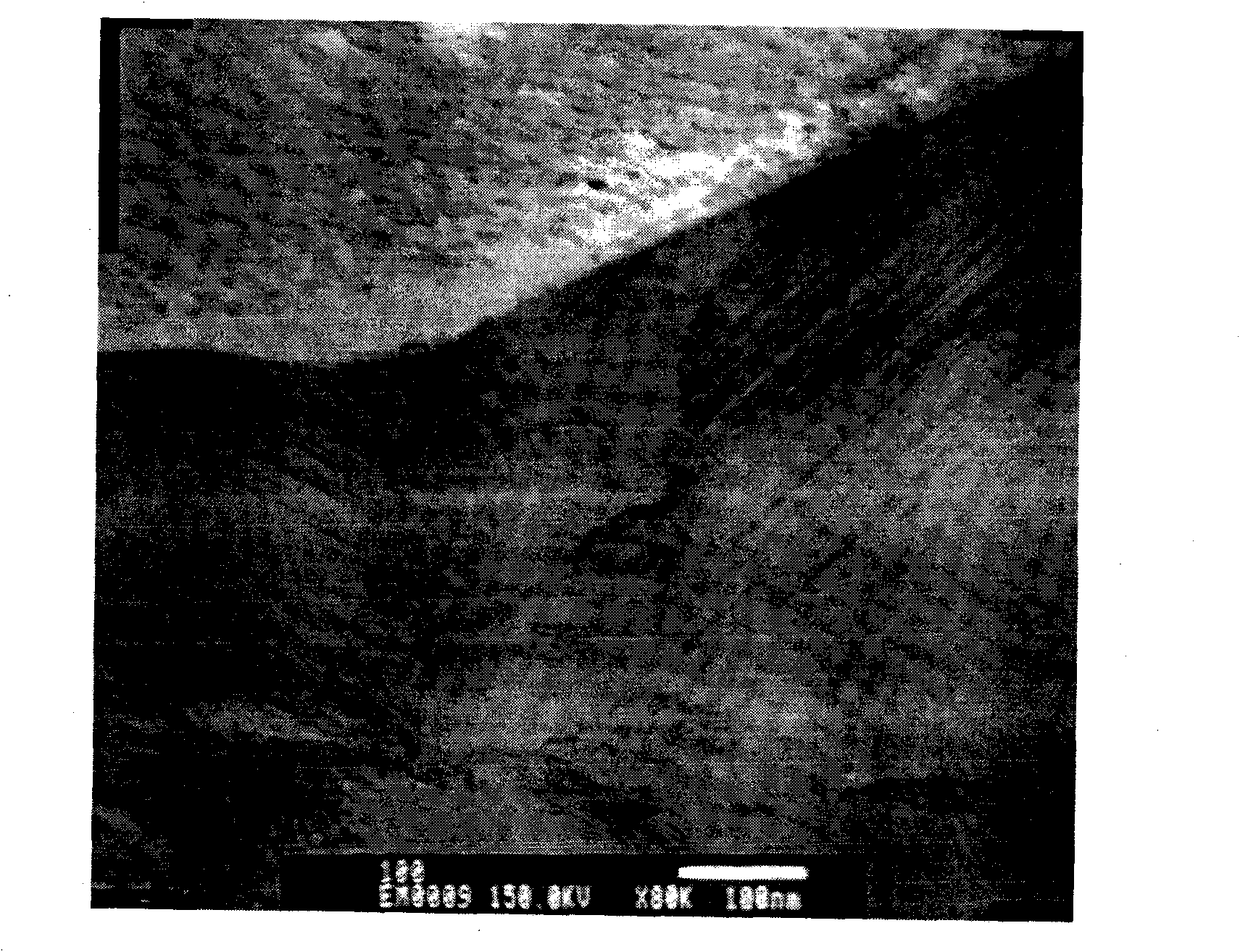

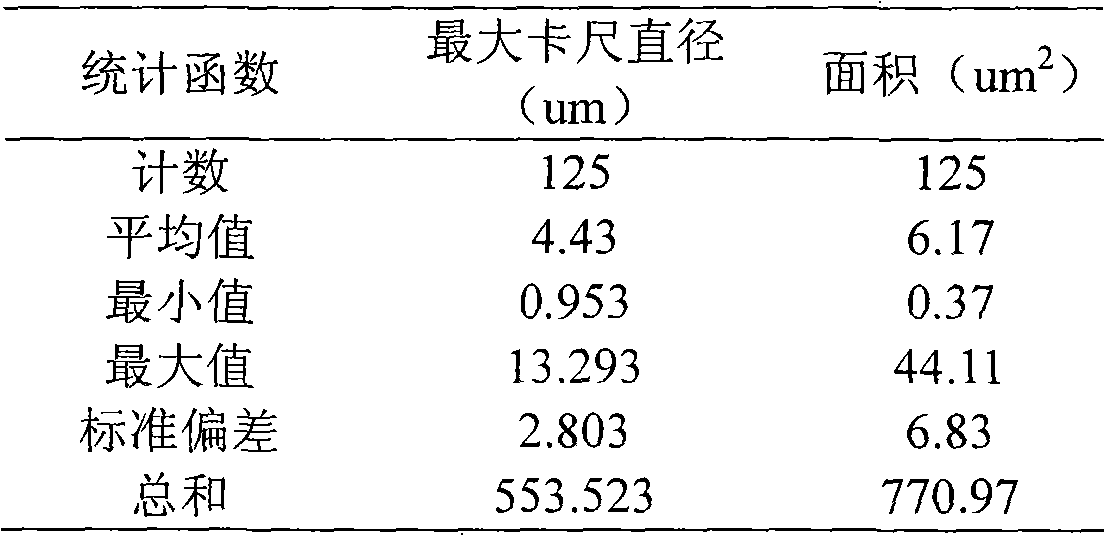

[0033] 5) Quantitative determination: observe under a metallographic microscope equipped with a color camera;

[0034] 6) Measure with metallographic quantitative analysis software, so as to obtain the results of martensite and ferrite in dual-phase steel.

Embodiment 2

[0036] Quantitative determination method of martensite in duplex steel, its steps:

[0037] 1) sodium metabisulfite and water are configured into an aqueous solution A with a concentration of 2.2% by mass;

[0038] 2) configuring picric acid and alcohol into a solution B with a concentration of 2.9% by mass;

[0039] 3) Prepare etchant: mix 2.2% aqueous solution A and 2.9% solution B at a volume ratio of 1:1 and stir evenly;

[0040] 4) Put the dual-phase steel sample into the etchant configured above, take out the sample after the surface of the dual-phase steel sample turns blue, and control the etching environment temperature at 18-25°C;

[0041] 5) Quantitative determination: observe under a metallographic microscope equipped with a color camera;

[0042] 6) Measure with metallographic quantitative analysis software, so as to obtain the results of martensite and ferrite in dual-phase steel.

Embodiment 3

[0044] Quantitative determination method of martensite in duplex steel, its steps:

[0045] 1) Sodium metabisulfite and water are configured into an aqueous solution A with a concentration of 3.0% by mass;

[0046] 2) Picric acid and alcohol are configured into a solution B with a concentration of 3.8% by mass;

[0047] 3) Prepare etchant: mix 3.0% aqueous solution A and 3.8% solution B at a volume ratio of 1:1 and stir evenly;

[0048] 4) Put the dual-phase steel sample into the etchant configured above, take out the sample after the surface of the dual-phase steel sample turns blue, and control the etching environment temperature at 20-30°C;

[0049] 5) Quantitative determination: observe under a metallographic microscope equipped with a color camera;

[0050] 6) Measure with metallographic quantitative analysis software, so as to obtain the results of martensite and ferrite in dual-phase steel.

[0051] After further analysis and identification of the brown-yellow part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com