Preparation method of isooctanol polyoxypropylene ether sodium sulfosuccinate diester

A technology of isooctyl alcohol polyoxypropylene ether and diester sodium sulfonate, which is applied in the direction of sulfonate preparation, chemical instruments and methods, organic chemistry, etc., can solve problems such as pollution, yield decline, and cost increase, and achieve reduction Effects of side reactions, short reaction time, and reduction in energy and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

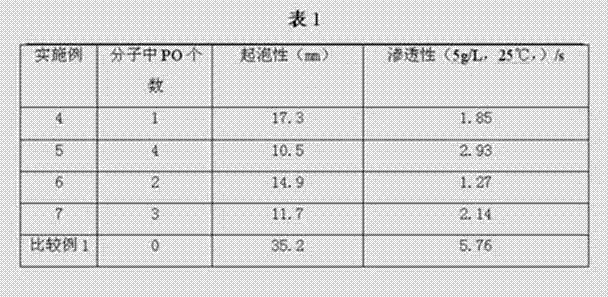

Examples

Embodiment 1

[0021] Solid Superacid S 2 O 8 2- / ZrO 2 Preparation of Catalyst 1

[0022] Pour 1000ml of zirconium oxychloride solution with a concentration of 0.6 mol / L into a 2000ml four-necked glass flask, stir and dropwise add 25% ammonia solution to adjust the pH value to 9, control the temperature below 20°C, precipitate and age for 36h, pump filtered, washed to be free of Cl - Detected, then dried at 105°C for 24 hours, ground to below 100 mesh, and set aside. Use 554 mL of ammonium persulfate solution with a concentration of 2.0 mol / L to impregnate the sample for a certain period of time, filter, dry at 105°C for 12 hours, and roast at 600°C for 6 hours to obtain solid superacid S 2 o 8 2- / ZrO 2 Catalyst, spare.

Embodiment 2

[0024] Solid Superacid S 2 O 8 2- / ZrO 2 Preparation of Catalyst 2

[0025] Pour 1000ml of zirconium oxychloride solution with a concentration of 1.0 mol / L into a 2000ml four-neck glass flask, stir and dropwise add 25% ammonia solution to adjust the pH value to 11, control the temperature below 20°C, precipitate and age for 12 hours, pump filtered, washed to be free of Cl - Detected, then dried at 105°C for 24 hours, ground to below 100 mesh, and set aside. Use 1476mL ammonium persulfate solution with a concentration of 1.25mol / L to impregnate the sample for a certain period of time, filter, dry at 105°C for 12h, and roast at 800°C for 2h to obtain solid superacid S 2 o 8 2- / ZrO 2 Catalyst, spare.

Embodiment 3

[0027] Solid Superacid S 2 O 8 2- / ZrO 2 Preparation of Catalyst 3

[0028] Pour 1000ml of zirconium oxychloride solution with a concentration of 0.2 mol / L into a 2000ml four-neck glass flask, stir and add 25% ammonia solution dropwise to adjust the pH value to 10, control the temperature below 20°C, precipitate and age for 24 hours, pump filtered, washed to be free of Cl - Detected, then dried at 105°C for 24 hours, ground to below 100 mesh, and set aside. Use 738mL ammonium persulfate solution with a concentration of 0.5mol / L to impregnate the sample for a certain period of time, filter, dry at 105°C for 12h, and roast at 400°C for 4h to obtain solid superacid S 2 o 8 2- / ZrO 2 Catalyst, spare.

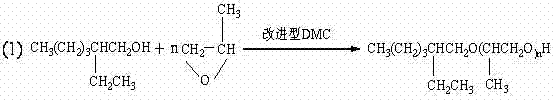

[0029] The preparation method of isooctyl alcohol polyoxypropylene ether succinic acid diester sodium sulfonate of the present invention, it comprises three main reactions, introduces condensation reaction and esterification emphatically below:

[0030] On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com