Film pasting device for tempered glass

A film sticking device and tempered glass technology, which is applied in the field of mechanical processing, can solve problems such as high labor intensity, high cost, and limited financial pressure of enterprises, and achieve the effects of efficient film sticking process, convenient production and processing, and simplified existing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

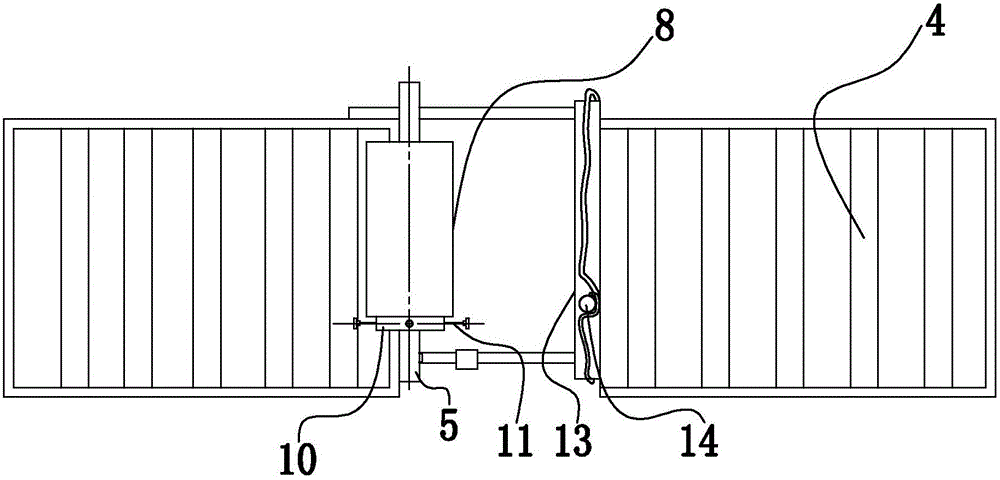

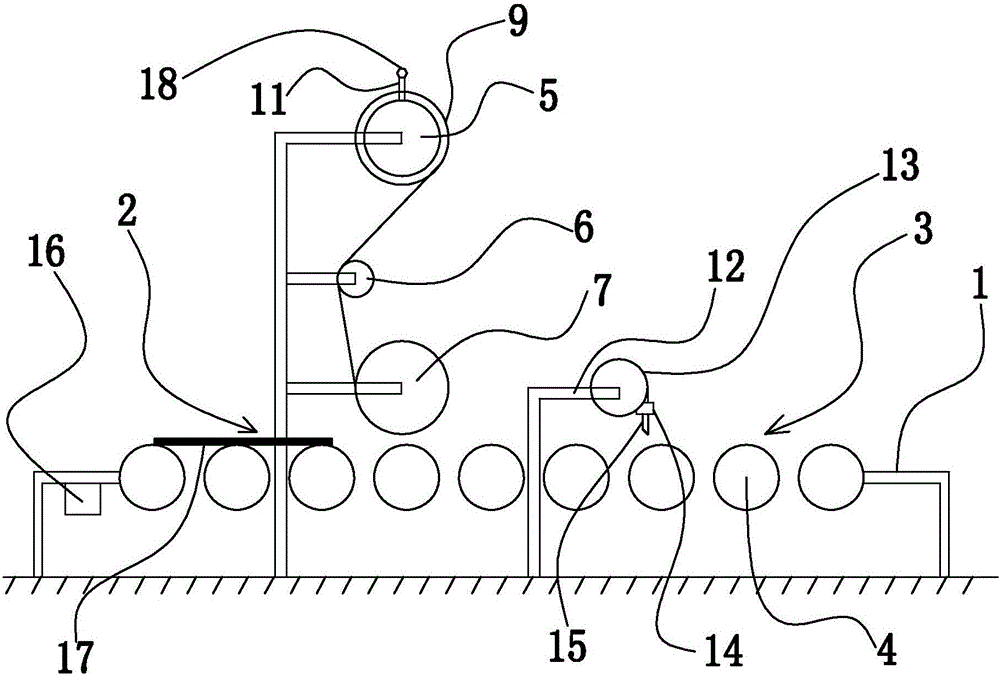

[0020] Example: such as Figure 1-2 As shown, a film sticking device for tempered glass includes a bracket 1, a transmission mechanism, a film sticking mechanism and a cutting mechanism; the transmission mechanism, the film sticking mechanism and the cutting mechanism are arranged on the support 1; the transmission mechanism is arranged on both sides of the support 1, The conveying mechanism includes a feed channel 2, a discharge channel 3 and a set of conveying rollers; both the feed channel 2 and the discharge channel 3 are provided with a set of conveying rollers; Equidistantly arranged on both sides of the bracket 1, and free to rotate, the film sticking mechanism includes a reel roller 5, an adjustment roller 6 and a pressing roller 7 arranged sequentially on the frame 1 from top to bottom; 5 is detachably sleeved with a film tube 9, and the film tube 9 is wound with a film 8, and the reel stick 5 and the film tube 9 are fixedly connected by an adjustment device; Foiled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com