Ft gtl apparatus and method for producing single synthetic crude oil

a synthetic crude oil and gastoliquid technology, applied in the field of ft gtl, can solve the problems of increased facilities and fuel supply, difficult use to secure flowability, etc., and achieve the effects of reducing transportation costs, saving deck space, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

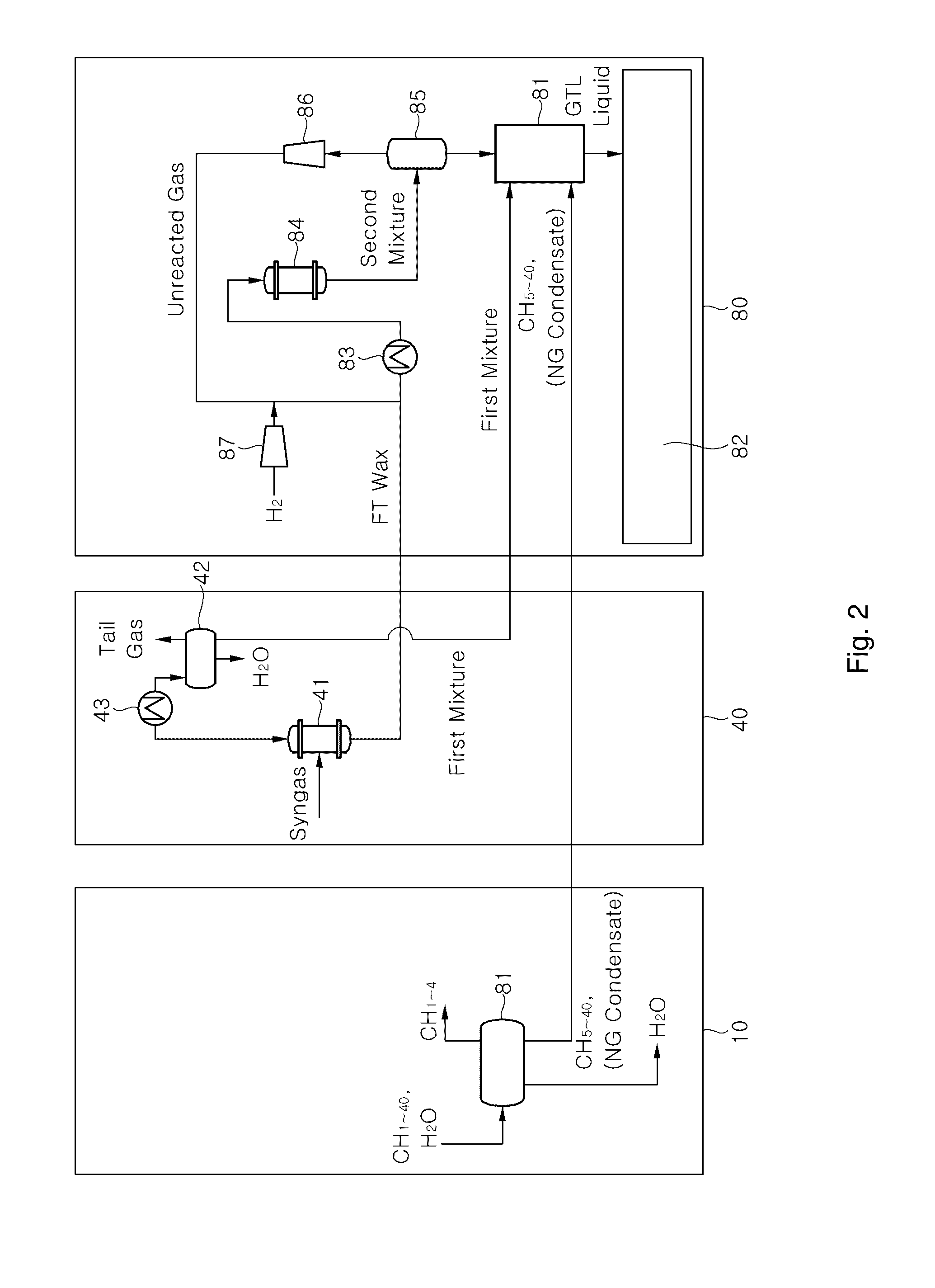

[0064]According to the invention, after FT naphtha is mixed with FT heavy oil, some of FT wax is subjected to a low level of general hydrocracking or mild hydroisomerization such that the synthetic crude oil can be transported without heat treatment. Such a concept includes transforming mixed synthetic crude oil such that the synthetic crude oil can be stored and transported without heat treatment, although the concept includes using a catalyst and operating system not intended to produce a final FT product. In addition, this concept also includes using different catalysts to produce different products without diluting (or mixing) FT naphtha and FT heavy oil with treated FT wax.

[0065]The above concept includes subjecting FT wax to hydrocracking or mild hydroisomerization in order to only increase the pour point and freezing point of the synthetic crude oil without trying to modify other properties. Thus, it is possible to reduce costs required for processing an FPSO on-board FT prod...

second embodiment

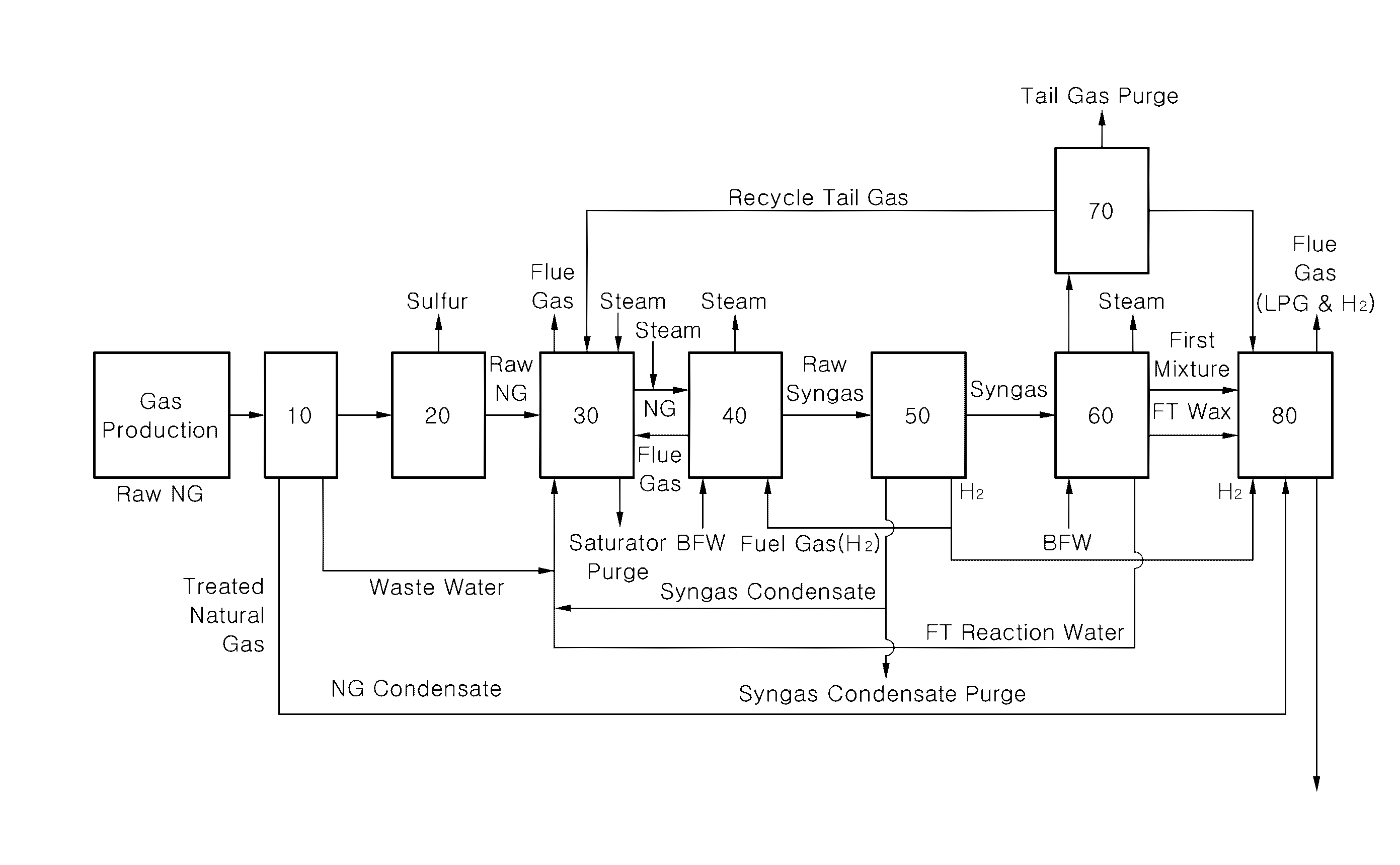

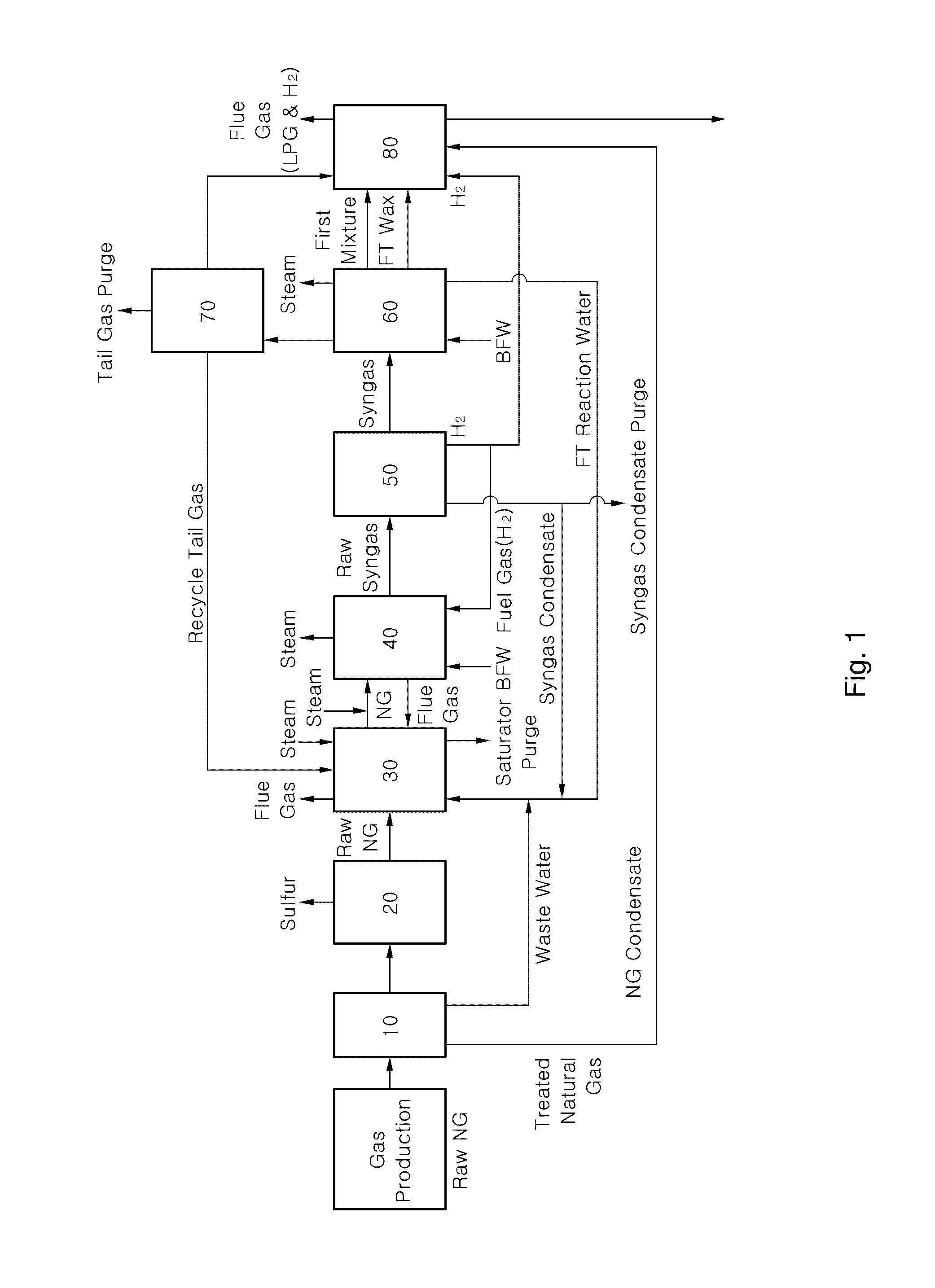

[0093]According to the invention, the FT synthesis unit 600 is provided to produce synthetic oil from syngas prepared from natural gas. Referring to FIG. 5, a GTL main process is performed by the natural gas saturation and pre-reforming unit 300, the reforming unit 400, the syngas conditioning unit 500, the FT synthesis unit 600, and the product treatment unit 800, which are sequentially connected to one another. The FT synthesis unit 600 serves to convert the syngas into the synthetic oil, and the product treatment unit 800 serves to upgrade the synthetic oil to produce a synthetic crude oil. A surplus syngas generated in the FT synthesis unit 600 is fractionated in the tail gas separation unit 700 to be partially recycled to the pre-reforming unit 20. The synthetic crude oil produced in the product treatment unit 800 is stored in a tank.

[0094]Here, since the synthetic crude oil produced in the GTL FPSO exhibits high viscosity due to containing a large amount of wax, it is necessar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow rates | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com