Gas soluble water separation technology device

A technology for a process device and a separation device, which is applied in heating devices, degassed water/sewage treatment, water heaters, etc., can solve the problems that water and gas cannot be effectively separated, cannot be used safely and conveniently, and difficult to store and transport natural gas. The effect of maximizing geothermal resources, reducing natural gas leakage, reducing safety hazards and investment in safety measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

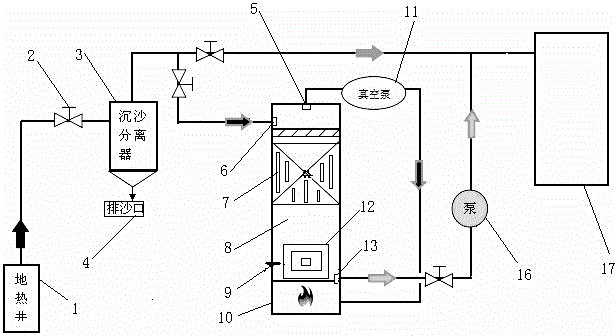

[0028] Such as figure 1 The shown dissolved gas water separation process device has an integrated separation tank 8, a natural gas burner 10, a heat exchange component 12, and a plurality of valves 2; the integrated separation tank 8 has a dissolved gas water inlet 6, a water outlet 13, The natural gas outlet 5 and the separated dissolved gas water are stored inside the separation tank 8. There is a heat exchange component 12 inside the separation tank 8. The natural gas from the natural gas outlet 5 enters the natural gas burner 10 for combustion, and the heat generated by it is used to heat the heat exchange unit. The component 12 further heats the water inside the separation tank, and the heated water finally flows out from the water outlet 13 to realize the separation and full utilization of natural gas.

[0029] The integrated separation tank 8 is internally connected with a water level gauge 9 and externally connected with a control device. The water outlet 13 of the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com