Demulsifying agent for treating natural gas condensate oil produced liquid as well as preparation method and application thereof

A technology of condensate oil and demulsifier, which is applied in the field of demulsifier for natural gas condensate oil production fluid treatment and its preparation, which can solve the problems of high dosage, difficulty in demulsification, poor pertinence of demulsifier, etc., and achieve good settlement , Large specific surface area, good detergency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

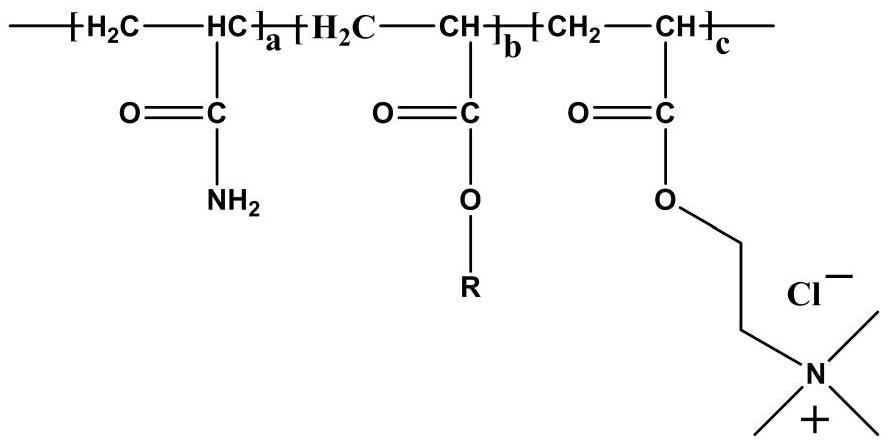

[0053] A demulsifier for natural gas condensate production liquid treatment, comprising the following raw materials and a preparation method, specifically: (1) preparing raw materials, including the following components in mass percentages:

[0054] Methanol 20%, monomer 67%, initiator ammonium persulfate 3% and deionized water 10%;

[0055] Wherein, the monomer comprises acryloyloxyethyltrimethylammonium chloride, isooctyl acrylate and acrylamide mixed in a molar ratio of 1:1:1;

[0056] (2) preparation method, comprises the following steps:

[0057] Mix water and methanol evenly in proportion and add them into a closed three-necked bottle, then pass through argon gas to deoxygenate for 30 minutes, and then add three monomers acryloyloxyethyltrimethylammonium chloride, isooctyl acrylate and propylene Amide, the feeding ratio between the acryloyloxyethyltrimethylammonium chloride, isooctyl acrylate and acrylamide is 1:1:1, stir and heat up to 60°C, use a constant pressure dro...

Embodiment 2

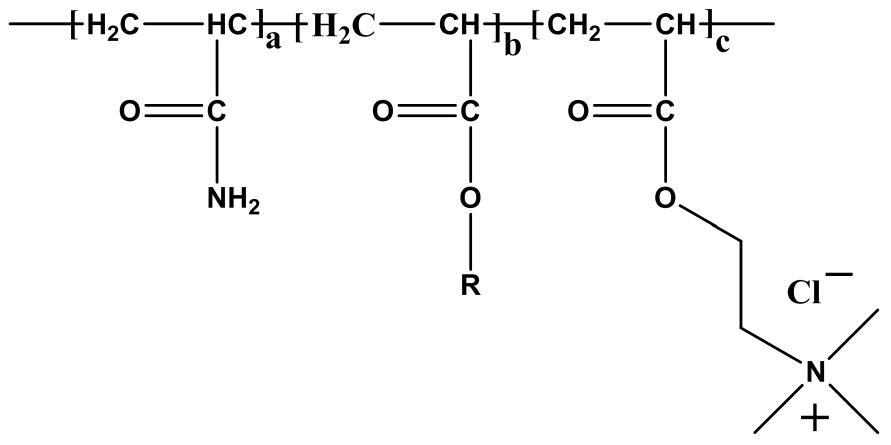

[0059] A demulsifier for natural gas condensate production liquid treatment, comprising the following raw materials and a preparation method, specifically: (1) preparing raw materials, including the following components in mass percentages:

[0060] Methanol 18%, monomer 72%, initiator potassium persulfate 4% and deionized water 6%;

[0061] Wherein, the monomer comprises acryloyloxyethyltrimethylammonium chloride, isobutyl acrylate and acrylamide mixed in a molar ratio of 3:1:1;

[0062] (2) preparation method, comprises the following steps:

[0063] Mix water and methanol evenly in proportion and add them into a closed three-necked bottle, then pass through argon gas to deoxygenate for 30 minutes, and then add three monomers acryloyloxyethyltrimethylammonium chloride, isobutyl acrylate and propylene Amide, the feeding ratio between the acryloyloxyethyltrimethylammonium chloride, isobutyl acrylate and acrylamide is 3:1:1, stir and heat up to 60°C, use a constant pressure dro...

Embodiment 3

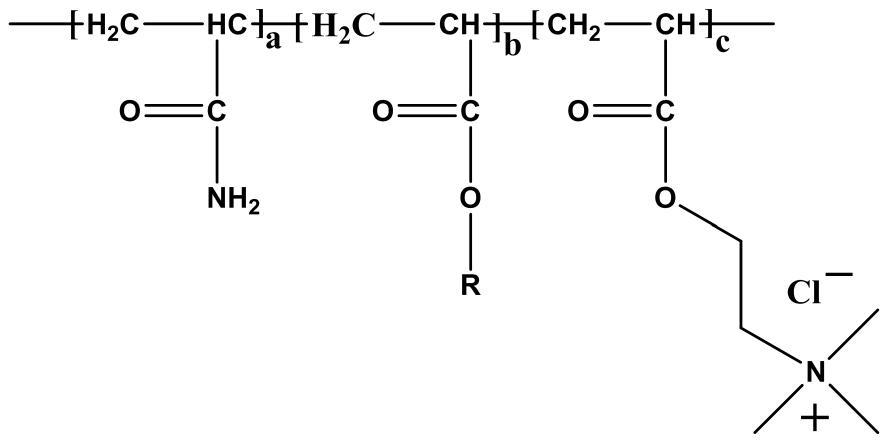

[0065] A demulsifier for natural gas condensate production liquid treatment, comprising the following raw materials and a preparation method, specifically: (1) preparing raw materials, including the following components in mass percentages:

[0066] Methanol 24%, monomer 68%, initiator potassium persulfate 4% and deionized water 4%;

[0067] Wherein, the monomer comprises acryloyloxyethyltrimethylammonium chloride, isobutyl acrylate and acrylamide mixed in a molar ratio of 1:2:1;

[0068] (2) preparation method, comprises the following steps:

[0069] Mix water and methanol evenly in proportion and add them into a closed three-neck bottle, then pass through argon gas to remove oxygen for 30 minutes, and then add three monomers acryloyloxyethyltrimethylammonium chloride, hydroxypropyl acrylate and propylene Amide, the feeding ratio between the acryloyloxyethyltrimethylammonium chloride, hydroxypropyl acrylate and acrylamide is 1:2:1, stir and heat up to 60°C, use a constant pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com