Miniature skid type nitrogen expansion natural gas liquefaction system and method thereof

A natural gas and skid-mounted technology, which is applied in liquefaction, refrigeration and liquefaction, gas fuel, etc., can solve the problems of complex devices and miniaturization of equipment, and achieve low energy consumption for liquefaction, facilitate equipment prying, and simplify the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

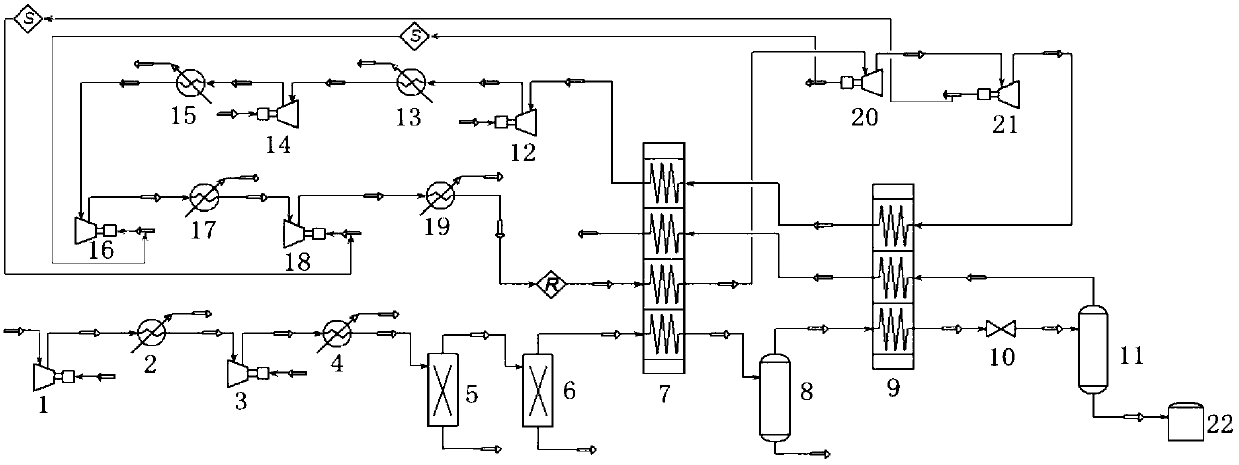

[0041] Natural gas molar composition 92% CH 4 +4%C 3 h 8 +4%N 2 , pressure 1.2MPa, temperature 30°C, flow rate 1kmol / h, the specific steps of the small skid-mounted nitrogen expansion natural gas liquefaction process are as follows:

[0042] 1. Natural gas is compressed to 2.85MPa by two-stage compressors (natural gas first-stage compressor 1, natural gas second-stage compressor 3), and then passes through coolers (natural gas first-stage cooler 2, natural gas second-stage water cooler 4) Cool to 40°C;

[0043] 2. The natural gas cooled in step 1 enters deacidification tower 5 and dehydration tower 6 to remove CO 2 , H 2 S, H 2 O and other impurities;

[0044] 3. The natural gas purified in step 2 is cooled to -60°C (i.e., the heavy hydrocarbon separation temperature) through the first stage heat exchanger 7, and then enters the heavy hydrocarbon separator 8 to obtain heavy hydrocarbons from the bottom;

[0045] 4. The natural gas after the removal of heavy hydrocarbon...

Embodiment 2

[0053] Natural gas molar composition 90% CH 4 +6%C 3 h 8 +4%N 2 , pressure 1.7MPa, temperature 25°C, flow rate 1kmol / h, the specific steps of the small skid-mounted nitrogen expansion natural gas liquefaction process are as follows:

[0054] 1. Natural gas is compressed to 2.85MPa by two-stage compressors (natural gas first-stage compressor 1, natural gas second-stage compressor 3), and then passes through coolers (natural gas first-stage cooler 2, natural gas second-stage water cooler 4) Cool to 40°C;

[0055] 2. The natural gas cooled in step 1 enters deacidification tower 5 and dehydration tower 6 to remove CO 2 , H 2 S, H 2 O and other impurities;

[0056] 3. The natural gas purified in step 2 is cooled to -60°C (i.e., the heavy hydrocarbon separation temperature) through the first stage heat exchanger 7, and then enters the heavy hydrocarbon separator 8 to obtain heavy hydrocarbons from the bottom;

[0057] 4. The natural gas after the removal of heavy hydrocarbon...

Embodiment 3

[0065] Natural gas molar composition 80% CH 4 +6%C 3 h 8 +14%N 2 , pressure 2.8MPa, temperature 20°C, flow rate 1kmol / h, the specific steps of the small skid-mounted nitrogen expansion natural gas liquefaction process are as follows:

[0066] 1. The natural gas pressure reaches 2.8MPa, so step 1 can be omitted;

[0067] 2. Natural gas enters deacidification tower 5 and dehydration tower 6 to remove CO 2 , H 2 S, H 2 O and other impurities;

[0068] 3. The natural gas purified in step 2 is cooled to -60°C (ie, the heavy hydrocarbon separation temperature) through the first-stage heat exchanger 7 and then enters the heavy hydrocarbon separator 8 to obtain heavy hydrocarbons from the bottom.

[0069] 4. The natural gas after the removal of heavy hydrocarbons in step 3 is cooled to -153°C through the second stage heat exchanger 9;

[0070] 5. The natural gas obtained in step 4 passes through a throttling valve 10, and after throttling and reducing the pressure to 0.30 MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com