A low energy consumption biomass liquefaction device

A liquefaction device and biomass technology, applied in the field of low-energy biomass liquefaction devices, can solve the problems of high energy consumption, low proportion of biomass diesel output, slow heating rate, etc., achieve high thermal efficiency, improve comprehensive utilization efficiency, reduce The effect of smoke loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

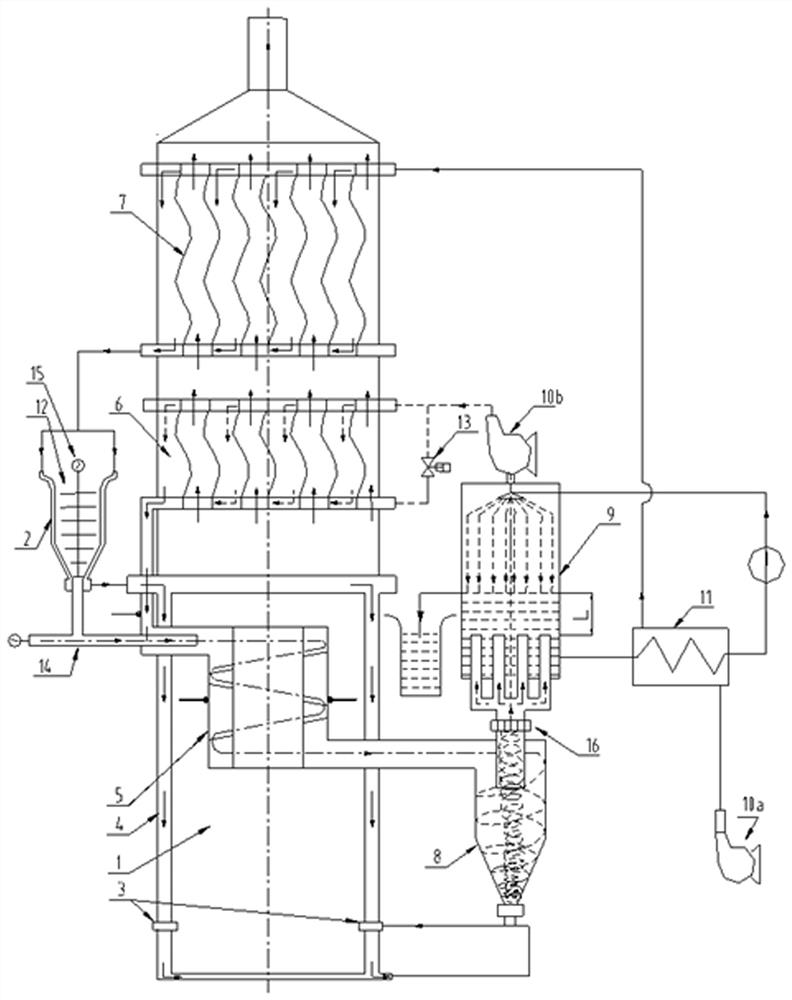

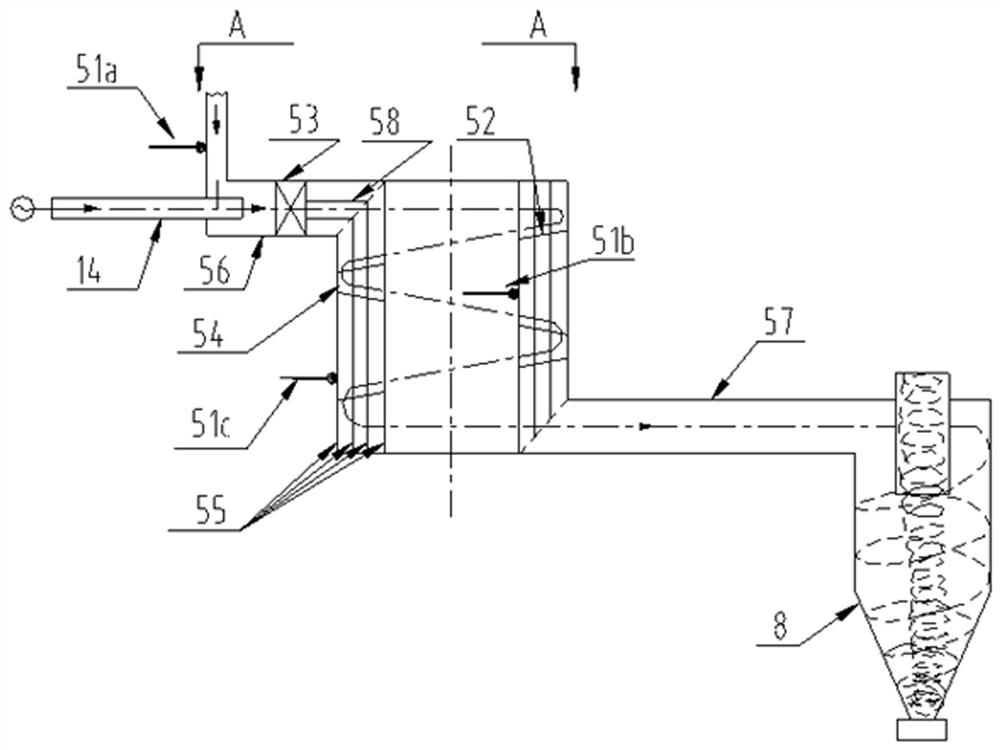

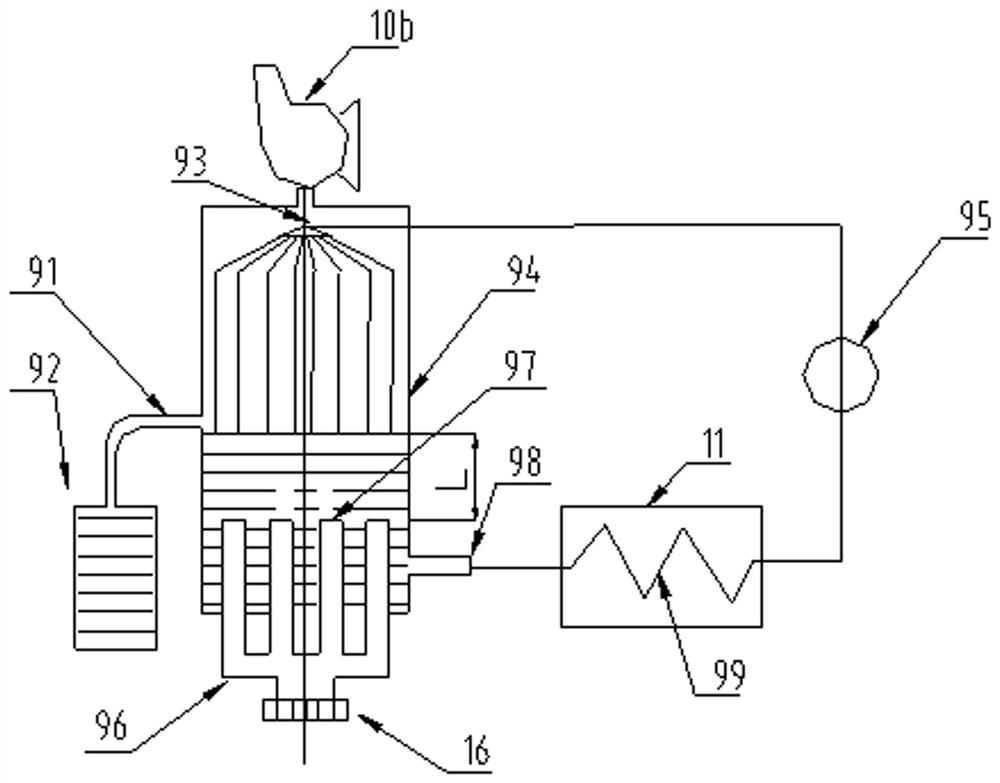

[0028] Such as figure 1 As shown, a low-energy biomass liquefaction device in this embodiment is characterized in that it includes a furnace 1, a silo heating jacket 2, a carbon powder burner 3, a three-stage jacketed air preheater 4, and a biomass Pyrolysis reactor 5, plate nitrogen preheater 6, secondary plate air preheater 7, gas-solid cyclone separator 8, rapid condensation system 9, fans 10a, 10b, primary tube air preheater 11, Biomass bin 12, electric control valve 13, screw feeder 14, agitator 15, metal filter 16, the furnace wall of the furnace 1 is surrounded by three-stage jacketed air preheater 4, carbon powder burner 3 Pass through the three-stage jacketed air preheater 4 and install it in the lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com