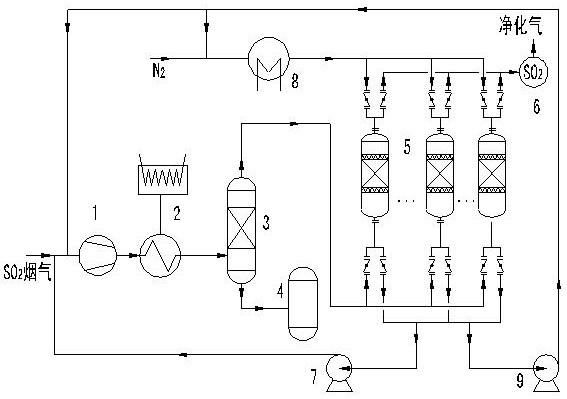

a kind of so 2 Flue gas treatment method and device

A treatment method, flue gas technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of uneconomical, no adsorption and concentration methods, etc., to reduce treatment costs, good environmental protection benefits and economic benefits, excellent Effect of SO2 physisorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

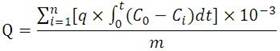

Examples

Embodiment 1

[0027] Contains SO 2 The gas is the regenerated flue gas of S-zorb adsorbent, which is pretreated by dust removal, cooling, dehydration and drying before compression and condensation, and the SO in the exhaust gas after treatment 2 The volume concentration of O is 2% to 5%. 2 The volume concentration is less than 0.2%, and the flue gas treatment capacity is 500Nm 3 / h.

[0028] Preparation of modified zinc-based metal-organic framework materials: using MOF-5 as the matrix, the specific surface area is 1655m 2 / g, the pore volume is 1.13cm 3 / g, Zn content 31.2%. The MOFs-5 were doped with 1.0% histidine by mass, and treated at 1000 °C for 6 hours in the presence of nitrogen to obtain modified Zn-based metal-organic framework materials.

[0029] will contain SO 2 The flue gas is compressed and condensed, the gauge pressure is controlled at 2.0MPaG, and the temperature is -10°C. After compression and condensation, it enters the condensation liquefaction unit, and the cond...

Embodiment 2

[0032] Contains SO 2 The gas is the regenerated flue gas of S-zorb adsorbent, which is pretreated by dust removal, cooling, dehydration and drying before compression and condensation, and the SO in the exhaust gas after treatment 2 The volume concentration is 3% to 10%, O 2 The volume concentration is less than 0.2%, and the flue gas treatment capacity is 1000Nm 3 / h.

[0033] Preparation of modified zinc-based metal-organic framework materials: using MOF-5 as the matrix, the specific surface area is 1655m 2 / g, the pore volume is 1.13cm 3 / g, Zn content 31.2%. The MOFs-5 were doped with 1.0% histidine by mass, and treated at 1000 °C for 6 hours in the presence of nitrogen to obtain modified Zn-based metal-organic framework materials.

[0034] will contain SO 2 The flue gas is compressed and condensed, the gauge pressure is controlled at 2.0MPaG, and the temperature is -15°C. After compression and condensation, it enters the condensation liquefaction unit, and the conde...

Embodiment 3

[0037] Contains SO 2 The gas is the regenerated flue gas of S-zorb adsorbent, which is pretreated by dust removal, cooling, dehydration and drying before compression and condensation, and the SO in the exhaust gas after treatment 2 The volume concentration is 2% to 5%, O 2 The volume concentration is less than 0.2%, and the flue gas treatment capacity is 500Nm 3 / h.

[0038] Preparation of modified zinc-based metal-organic framework materials: using MOF-5 as the matrix, the specific surface area is 1655m 2 / g, the pore volume is 1.13cm 3 / g, Zn content 31.2%. The MOFs-5 were doped with 1.0% histidine by mass, and treated at 1000 °C for 6 hours in the presence of nitrogen to obtain modified Zn-based metal-organic framework materials.

[0039] will contain SO 2 The flue gas is compressed and condensed, the gauge pressure is controlled at 1.0MPaG, and the temperature is -15°C. After compression and condensation, it enters the condensation liquefaction unit, and the condens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com