Anti-drag and anticorrosion coating for inner wall of natural gas/condensed liquid pipeline and preparation method thereof

A technology of condensate and natural gas, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor wear resistance, poor permeability resistance, and low bonding strength, and achieve high coating thickness, The curing speed is fast and the effect of reducing the number of construction passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

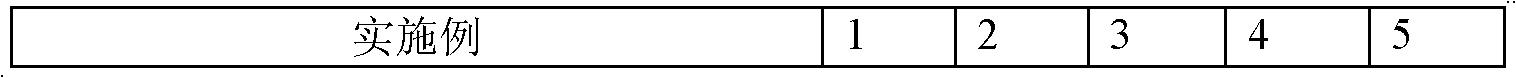

[0032] Example 1-5, Preparation and performance test of drag-reducing and anti-corrosion coating for inner wall of natural gas / condensate pipeline

[0033] The drag-reducing anti-corrosion coating is composed of components A and B, and the mass ratio of components A and B in each embodiment is shown in Table 1.

[0034] The mass proportion of component A and B in table 1, embodiment 1-5

[0035]

[0036]

[0037] Preparation:

[0038] 1. Preparation of Component A:

[0039] 1. Pretreatment of pigments and fillers

[0040] Heat the pigments and fillers in a constant temperature blast furnace at 180±20°C for ≥1 hour to remove volatile impurities and physical crystallization moisture; use a constant temperature high-speed mixer to mix the pigments, fillers and silane coupling agent (or titanate) Disperse to make a mixed color material.

[0041] 2. Prepolymerization

[0042] Put the silicone resin, liquid epoxy resin and toughening agent in the reaction kettle, carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com