Process method for producing LNG from oilfield associated gas

A technology of oilfield associated gas and process method, which is applied in the field of oilfield associated gas production LNG technology, which can solve the problems of lack of light hydrocarbon stabilizing device and freeze blockage of cold box, etc., and achieve the effects of reducing the risk of freeze blockage, lightening load and avoiding poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

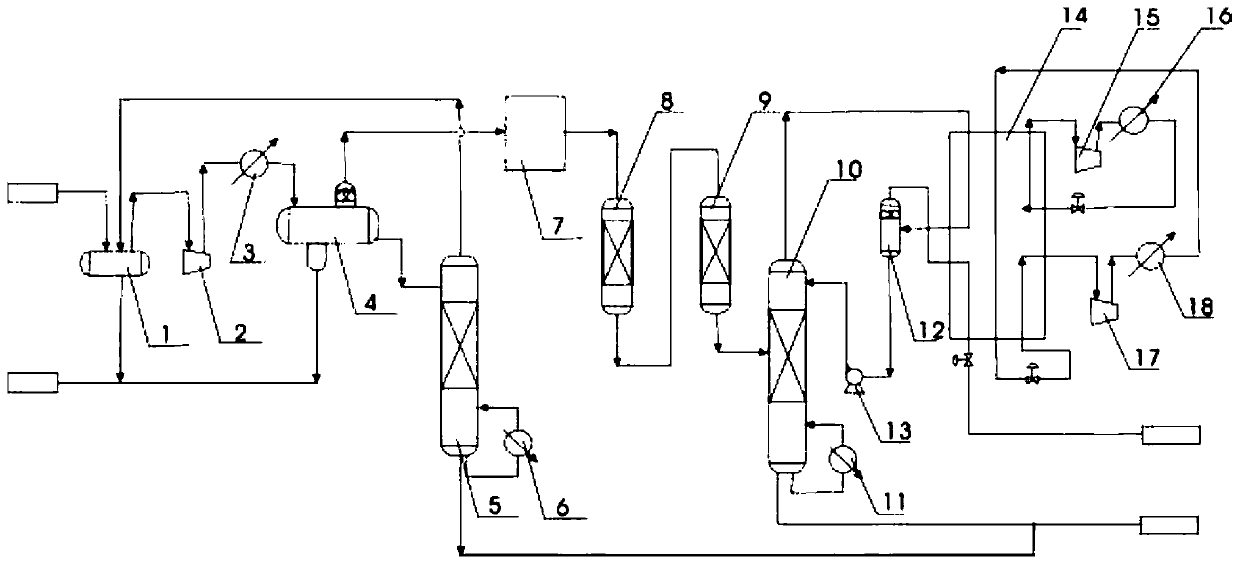

[0026]The invention provides a process for producing LNG from associated gas in an oilfield, which includes a raw material gas buffer tank, a raw material gas compressor, a raw material gas cooler, a three-phase separation tank, a stabilized light hydrocarbon tower, a stabilized light hydrocarbon tower reboiler, decarbonization and desulfurization System, molecular sieve dryer, mercury removal tank, heavy hydrocarbon tower, reboiler, low temperature gas-liquid separator, heavy hydrocarbon reflux pump, cold box, pre-cooling compressor unit, pre-cooling compressor unit condenser, main cooling compressor unit, main The condenser of the cold compressor unit, the external raw material gas enters the raw material gas buffer tank through the delivery pipeline, and the raw material gas buffer tank is respectively connected with the waste water output pipeline, the raw material gas compressor, and the stable light hydrocarbon tower through the delivery pipeline, and the raw material gas ...

Embodiment 2

[0028] Oilfield associated gas production LNG process method of the present invention, its concrete use method is:

[0029] The raw material gas is pressurized to 40-50 bar through the three-stage booster unit, cooled to 45°C by the air cooler, then cooled to 15-20°C by the pre-cooling heat exchanger, and then separated by the three-phase separator, and the gas phase enters the gas phase In the processing unit, the oil phase enters the stable light hydrocarbon tower, and a reboiler is installed at the bottom of the tower. The heat transfer oil or steam is used as the heat source, and the temperature is controlled at 100 ° C ~ 140 ° C. Through heating, the light components are evaporated from the top of the tower and enter the raw material The gas tank, the water phase enters the sewage tank; the gas phase entering from the three-phase separator passes through the decarbonization and desulfurization system, the molecular sieve dryer, and the mercury removal tank in turn; the tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com