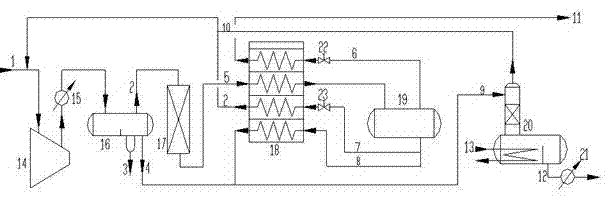

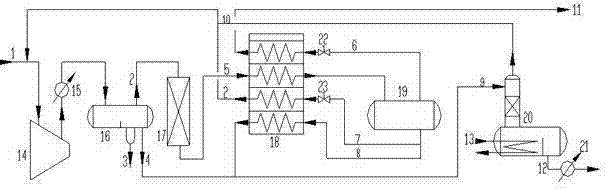

A natural gas condensate recovery device and method using mixed light hydrocarbon as refrigerant

A recovery method and technology of natural gas, applied in refrigeration and liquefaction, liquefaction, solidification, etc., can solve problems such as high cost and complicated process flow, and achieve the effect of simplifying process flow and equipment and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A natural gas condensate recovery device that mixes light hydrocarbons as a refrigerant, at least including: a compressor 14, a first cooler 15, a three-phase separator 16, a molecular sieve dehydrator 17, a cold box 18, a low temperature separator 19 and a condensate stabilizer In the tower 20, the input end of the compressor 14 is connected to the raw material gas 1 pipeline rich in liquefied gas components, the pressurized output end of the compressor 14 is connected to the high-temperature end pipe fitting of the first cooler 15, and the low-temperature output end of the first cooler 15 Connected to the input end of the three-phase separator 16, the three-phase separator 16 is divided into three outputs, the oily sewage 3 input end is connected to the sewage system pipeline, and the three-phase separator gas 2 output end of the three-phase separator 16 is connected to the molecular sieve dehydration 17 The input end is connected to the pipeline, and the unstabilized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com