Batch ceramic tile cutting device

A cutting device and batch technology, applied in the direction of work accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of low work efficiency, manual placement and removal of tiles, etc., and achieve the effect of improving cutting efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

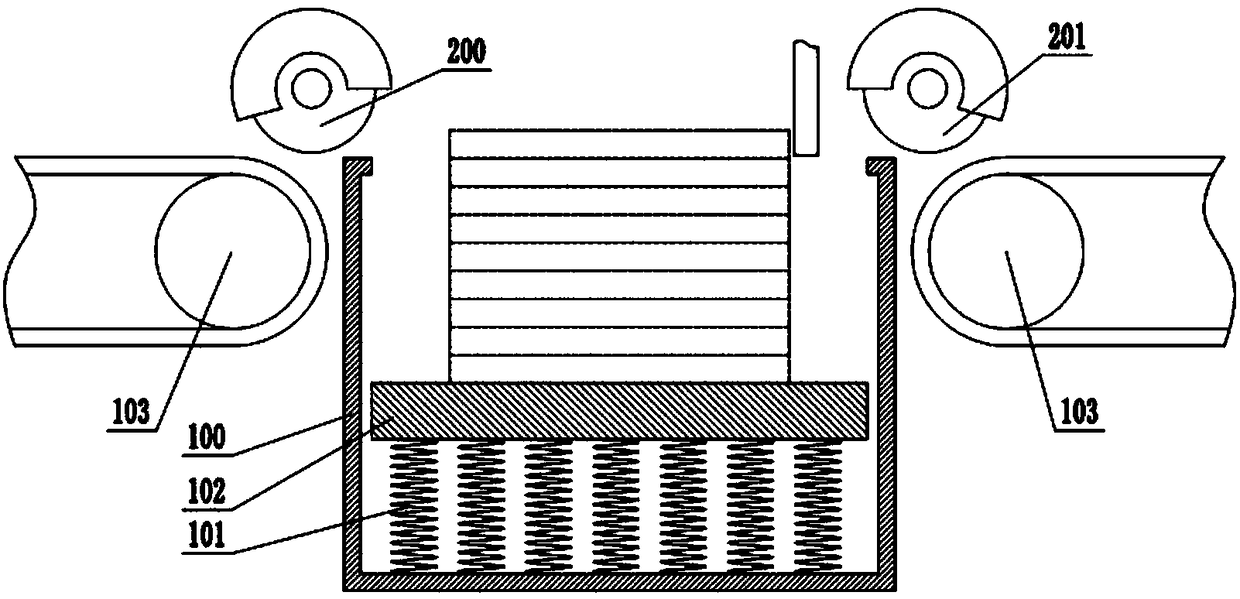

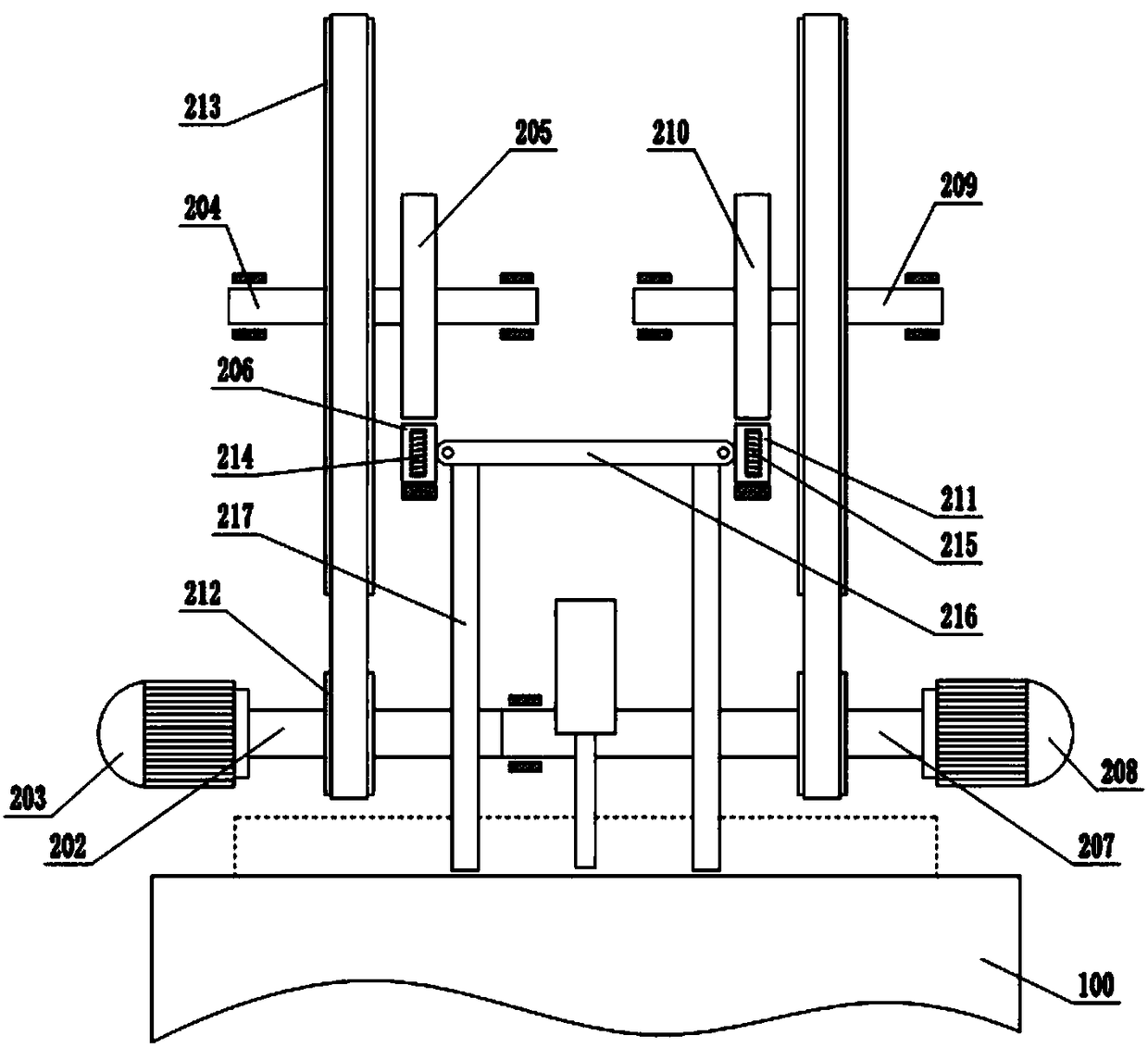

[0026] Such as figure 1 Shown is the first embodiment of the present invention, which announces a ceramic tile batch cutting device, including a frame, a working box 100 and a cutting device, an elastic member 101 is arranged at the bottom of the working box 100, and a support plate 102 is arranged above the elastic member 101 , when no tiles are placed on the support plate 102, the support plate 102 is higher than the upper surface of the work box 100, and the height of the support plate 102 beyond the surface of the work box 100 is the thickness of a tile, wherein the elastic member 101 can adopt devices such as springs, And every time a ceramic tile is placed on the support plate 102, the elastic member 101 moves downward by a displacement of the thickness of the ceramic tile, so that during the continuous processing of multiple ceramic tiles, one ceramic tile is exposed from the upper surface of the work box 100 for cutting. ; The left and right sides of the working box 10...

Embodiment 2

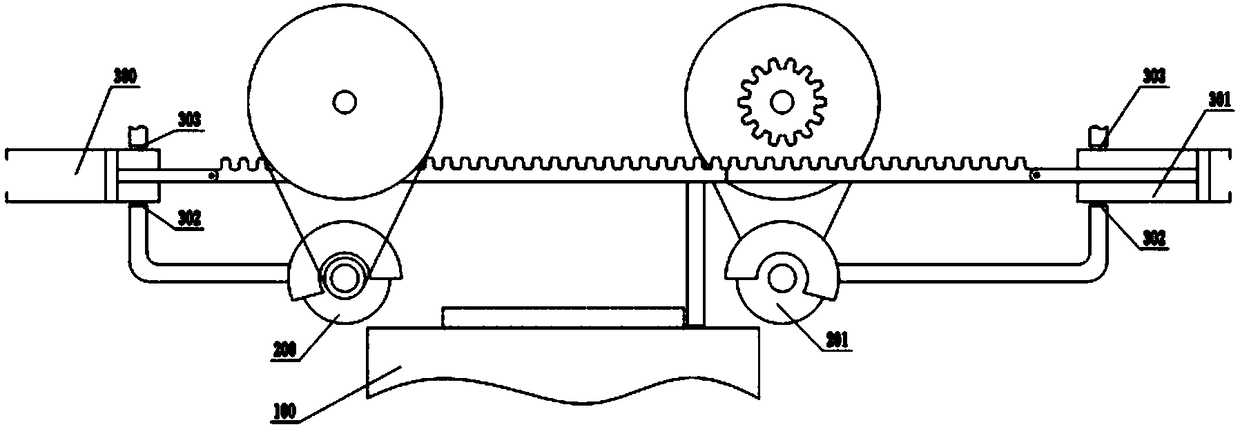

[0032] Such as image 3 Shown is Embodiment 2 of the present invention, and the difference from Embodiment 1 is: the first air cylinder 300 fixed on the frame is hinged at the left end of the first rack 206, and the right end of the second rack 211 is hinged with a cylinder fixed on the frame. On the second cylinder 301 on the first cylinder 300 and the cylinder side wall on the side of the piston rod of the second cylinder 301 are provided with an intake check valve 302 and an air outlet check valve 303, the first cutting wheel 200 and the second The periphery of cutting wheel 201 is provided with a semicircular casing, and the casing is provided with an air inlet, and the intake check valve 302 of the first cylinder 300 and the second cylinder 301 is connected to the first cutting wheel 200 and the second through the pipeline respectively. The suction port on the casing of the cutting wheel 201 is connected, and each air outlet check valve 303 is connected with a recovery de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com