Metal oxide ordered self-assembly patterned preparation method and metal oxide film

A technology of oxide film and oxide, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of wasting raw materials, damaging metal oxide semiconductors, and polluting the environment with etching liquid, and achieves the effect of low consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

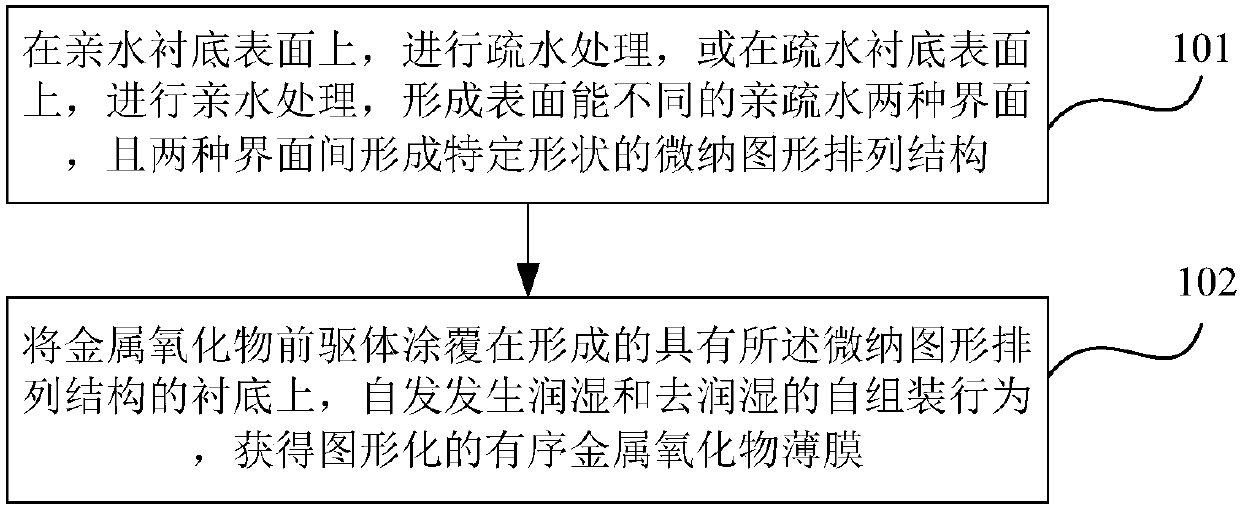

[0028] Such as figure 1 As shown, it is a flow chart of a metal oxide ordered self-assembly patterned preparation method according to an embodiment of the present invention, and the method includes:

[0029] 101. Perform hydrophobic treatment on the surface of the hydrophilic substrate, or perform hydrophilic treatment on the surface of the hydrophobic substrate to form two hydrophilic and hydrophobic interfaces with different surface energies, and form micro-nano patterns of specific shapes between the two interfaces arrangement structure;

[0030] 102. Coating the metal oxide precursor on the formed substrate having the micro-nano pattern arrangement structure, spontaneously occur the self-assembly behavior of wetting and dewetting, and obtain a patterned ordered metal oxide film.

[0031] Preferably, the hydrophilic substrate comprises: glass, quartz, silicon dioxide, silicon or other hard or flexible substrates through hydrophilic treatment; the hydrophilic treatment meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com