Model test device for shield-tail grouting slurry condensing and duct piece floating processes

A model test device and grouting technology, which is applied in the investigation stage/state change, etc., can solve the problems that the segment cannot be simulated to float up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

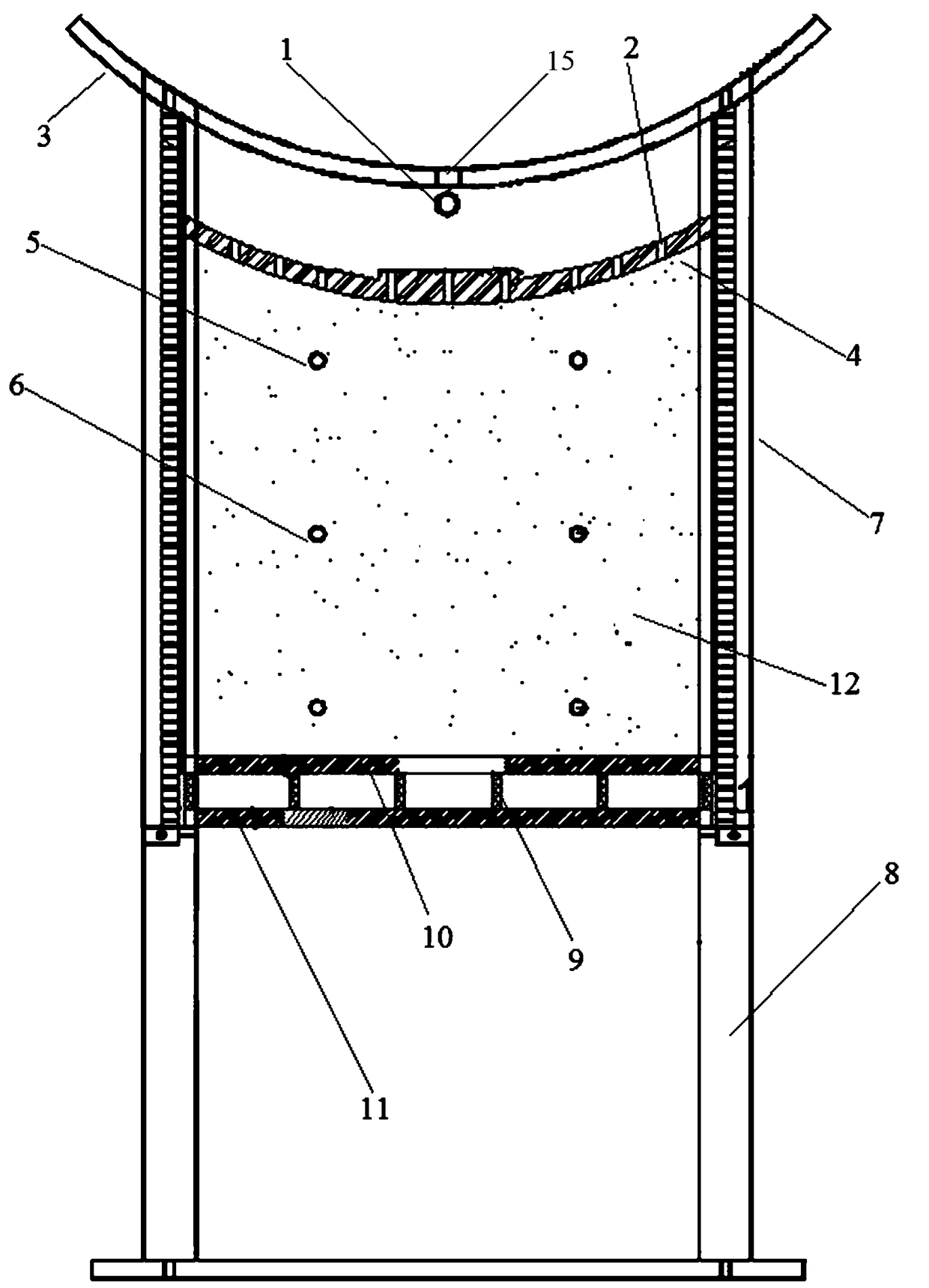

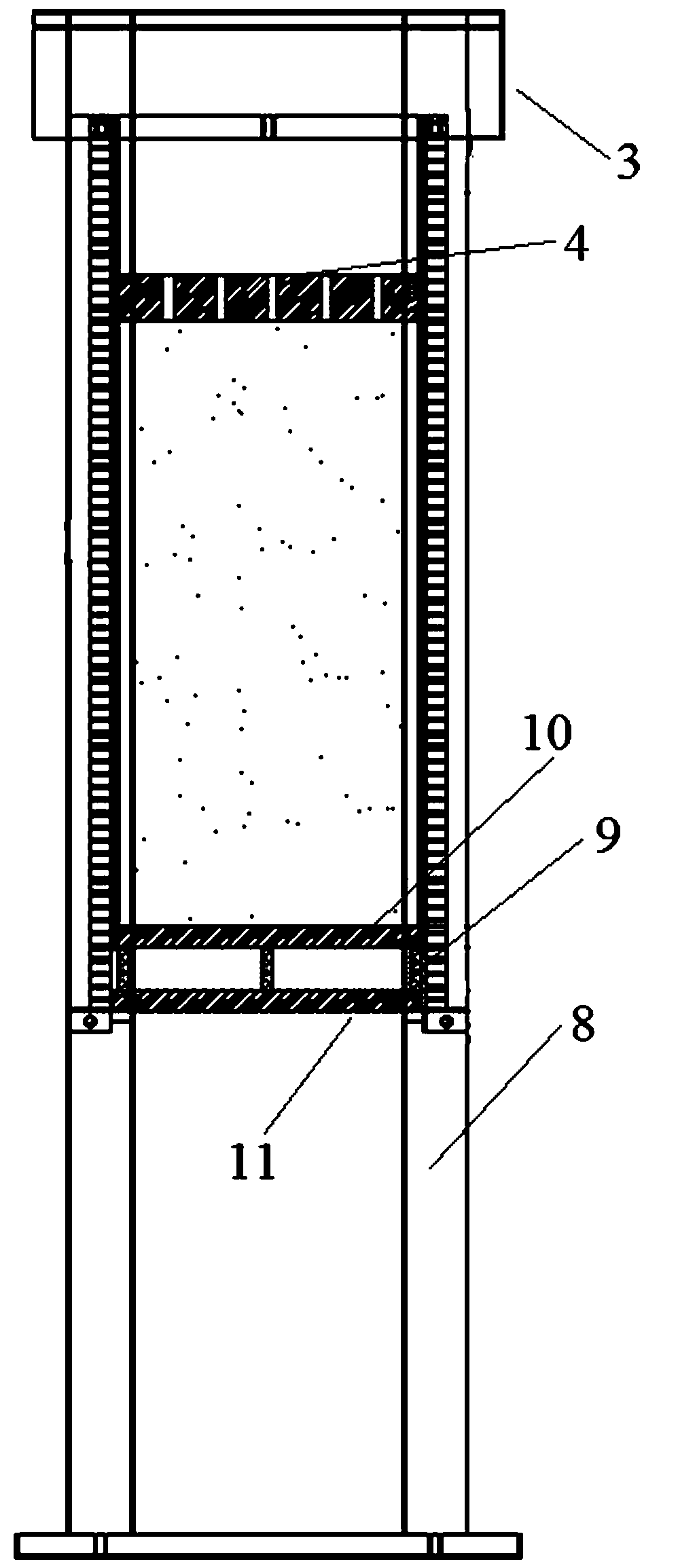

[0020] Example of a shield tail grouting slurry coagulation and segment uplift process model test device Figure 1~2 Shown: a model box 7 including an inner cavity for filling model soil, and the model box 7 is fixedly connected to the model box support frame 8 by bolts. The inner wall of the model box is pasted with a double-layer anti-slip film. In this embodiment, the anti-slip film is made of Teflon film, and graphite is filled between the two Teflon films to reduce the gap between the two-layer Teflon film. friction force, the top of the model box is connected with a steel pipe sheet model 3 through a detachable fixed structure, the detachable fixed structure includes locking bolts with the axis extending in the up and down direction and a model box threaded hole set on the model box, the steel pipe sheet model 3 The upper end of the model box 7 is fixed on the locking bolts that are installed in the threaded holes of the model box, and the lower peripheral surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com