Concrete buoy equipment capable of floating and diving and floating and diving method

A technology of concrete and buoys, applied to floating buildings and other directions, can solve the problems of not being able to resist extreme sea conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

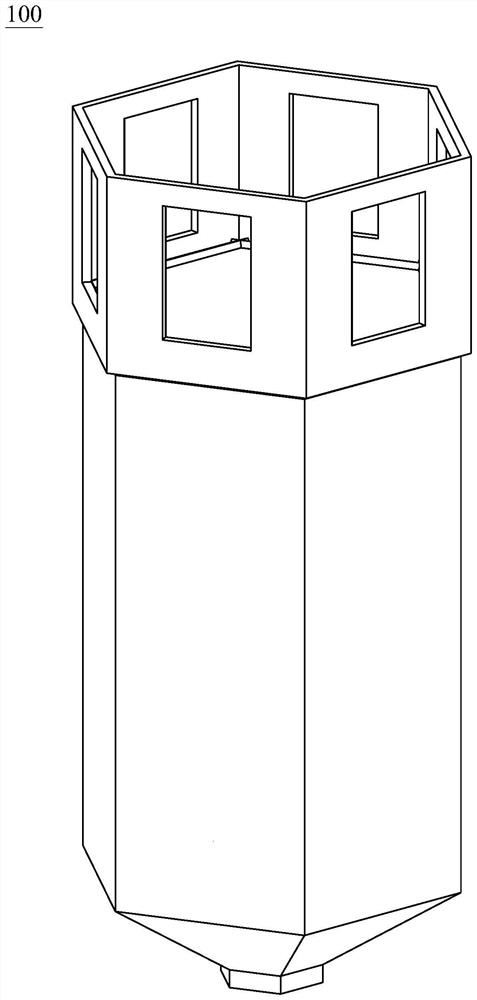

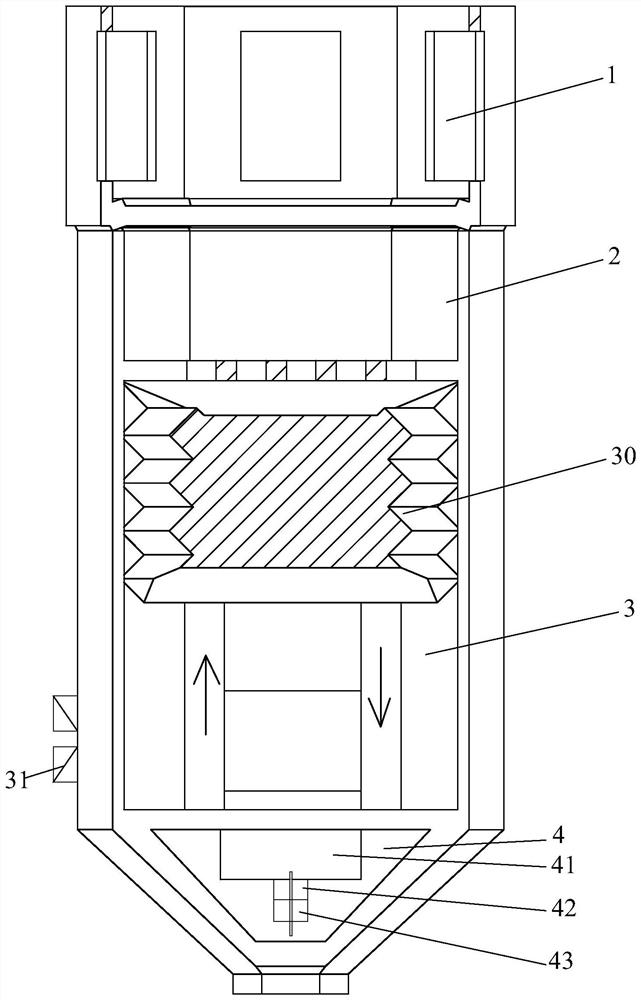

[0033] The concrete buoy equipment 100 that can be floated up and down disclosed in the embodiment of the present invention can be a floating platform that can be connected together by a plurality of pieces. Because the concrete buoy 100 disclosed in the present invention can quickly dive to avoid threats such as strong typhoons, tsunamis, collisions, etc., and prevent the floating structure from being damaged or even collapsed and sinking in these threats. The concrete buoy of the present invention can properly cope with the threats of these extreme sea conditions, and has strong continuous survivability under extreme sea conditions. Therefore, the concrete buoy of the present invention can be applied not only in the offshore, but also in the far-reaching marine engineering.

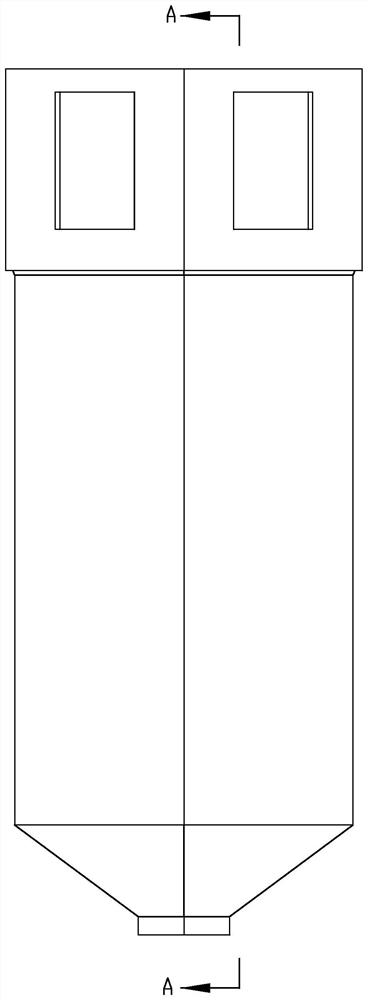

[0034] Embodiments of the present invention will now be described with reference to the accompanying drawings. as above, as Figure 1-3 As shown, the first technical solution provided by the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com