Kitchen fume purifying aqueous solvent and preparation method thereof

A technology for oil fume purification and water solvent, applied in chemical instruments and methods, separation methods, use of liquid separation agents, etc., can solve the problems of high oil fume removal efficiency, unsatisfactory oil adsorption, etc. The maximum amount of oil dirt adsorption, the effect of easy aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

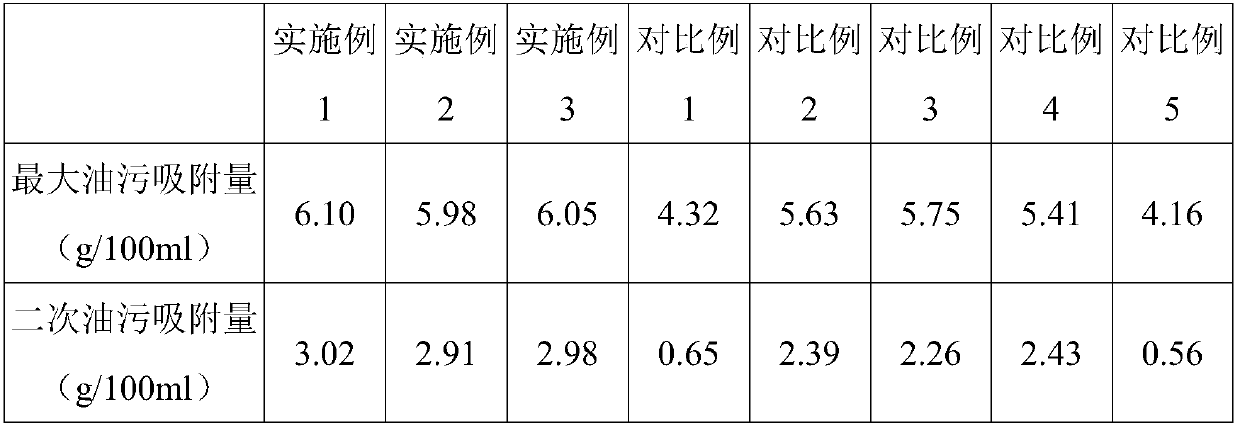

Examples

preparation example Construction

[0030] The preparation method of the above kitchen oil fume purification water solvent comprises the following steps:

[0031] (1) Fatty alcohol polyoxyethylene ether sulfate is dissolved in water, stirred and dissolved, and mixed uniformly;

[0032] (2) Dissolving polydiallyldialkylammonium chloride, carboxymethyl cellulose fiber, and fumed silica in hot water at 80°C, and cooling;

[0033](3) Add sodium dodecylbenzene sulfonate, nonylphenol polyoxyethylene ether-10, isopropanol, triethanolamine, sodium silicate and sodium citrate to step 1 under the environment of 25℃~50℃ In the resulting solution, stir the whole process, and after mixing evenly, add the solution in step 2, and mix evenly to get ready.

Embodiment 1

[0036] A solvent for purifying kitchen oil fumes, comprising the following raw materials in parts by mass: 16 parts by mass of sodium dodecylbenzene sulfonate, 8 parts by mass of sodium fatty alcohol polyoxyethylene ether sulfate, 5 parts by mass of nonyl Phenol polyoxyethylene ether-10, 1 mass part of isopropanol, 1 mass part of triethanolamine, 2 mass parts of sodium silicate, 2 mass parts of sodium citrate, 8 mass parts of polydiallyl dioxane ammonium chloride, 3 parts by mass of carboxymethyl cellulose fibers, 0.8 parts by mass of fumed silica, and 65 parts by mass of water.

[0037] The preparation method of the above kitchen oil fume purification water solvent comprises the following steps:

[0038] (1) Fatty alcohol polyoxyethylene ether potassium sulfate is dissolved in water, stirred and dissolved, and mixed uniformly;

[0039] (2) Dissolving polydiallyldialkylammonium chloride, carboxymethyl cellulose fiber, and fumed silica in hot water at 80°C, and cooling;

[00...

Embodiment 2

[0042] A solvent for purifying kitchen oil fumes, comprising the following raw materials in parts by mass: 5 parts by mass of sodium dodecylbenzenesulfonate, 10 parts by mass of fatty alcohol polyoxyethylene ether potassium sulfate, 1 part by mass of nonyl Phenol polyoxyethylene ether-10, 5 parts by mass of isopropanol, 1 part by mass of triethanolamine, 5 parts by mass of sodium silicate, 1 part by mass of sodium citrate, 10 parts by mass of polydiallyl dioxane ammonium chloride, 2 parts by mass of carboxymethyl cellulose fibers, 1 part by mass of fumed silica, and 40 parts by mass of water.

[0043] The preparation method of the above kitchen oil fume purification water solvent comprises the following steps:

[0044] (1) Fatty alcohol polyoxyethylene ether potassium sulfate is dissolved in water, stirred and dissolved, and mixed uniformly;

[0045] (2) Dissolving polydiallyldialkylammonium chloride, carboxymethyl cellulose fiber, and fumed silica in hot water at 80°C, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com