Improved anti-crack construction technique for aerated concrete block wall

A technology of aerated concrete and construction technology, which is applied in the treatment of walls, building materials, and building components, etc., and can solve problems that affect the use and aesthetic functions of buildings, improper construction methods and design measures, and hollow plastering on walls, etc. , to achieve the effect of meeting the wall crack resistance requirements, good promotion prospects, and easy construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0050] refer to figure 1 , the present embodiment adopts the following technical solutions:

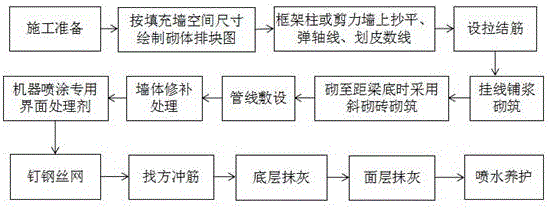

[0051] An improved anti-crack construction technology for aerated concrete block walls, the process flow is: construction preparation - drawing masonry block arrangement diagram according to the space size of the filled wall - leveling and popping the axis of frame columns or shear walls , Scratching and counting lines - setting tie bars - hanging line grouting masonry - using inclined brick masonry when building to the bottom of the beam - laying pipelines - wall repair treatment - special interface treatment for machine spraying Agent—nailing steel wire mesh—finding squares and punching tendons—bottom layer plastering—surface layer plastering—spraying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com