Suction type foundation used on sea-bottom

A suction-based foundation, integrated technology, applied in infrastructure engineering, hydraulic engineering, artificial islands, etc., can solve problems such as poor horizontal dynamic load capacity, reduced soil strength, loss, etc., to improve constraints, eliminate liquefaction, reduce The effect of the degree of softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

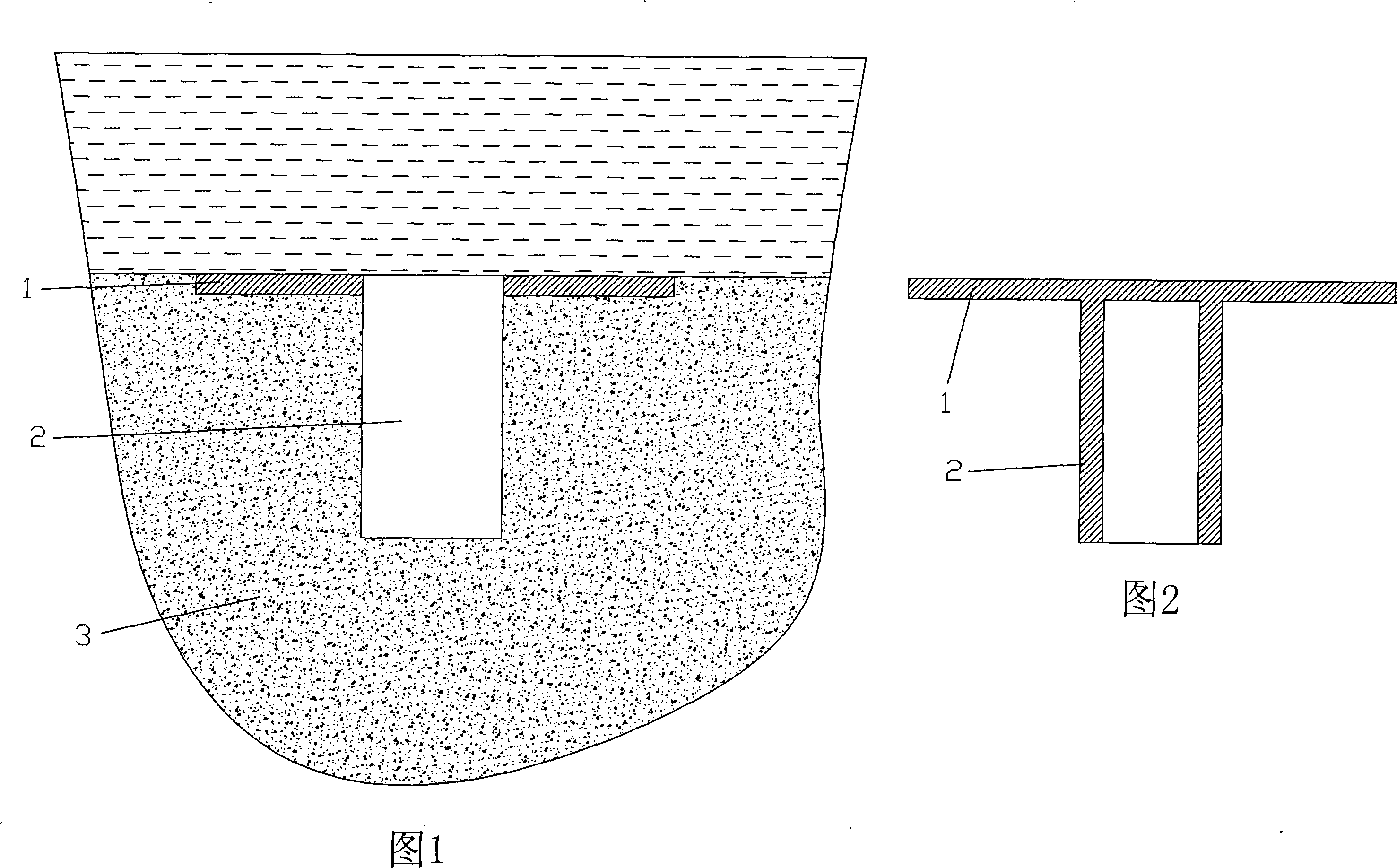

[0010] As shown in Figure 1, on the existing bucket foundation (both barrel-shaped body 2) with the suction foundation of the present invention, an annular stabilizing disk 1 is added at its upper end, and this annular stabilizing disk 1 is in phase with the barrel-shaped body 2. fixed, and the radius of the outer edge of the annular stabilizing disc 1 is approximately the same as the length of the barrel basic body 2 .

[0011] When fixing the foundation into the seabed soil, it must be ensured that the annular stabilization disc 1 is reliably pressed against the seabed soil 3 .

[0012] According to the test results, it is found that the radius of the softened or liquefied soil around the existing bucket base is roughly equivalent to the length of the bucket base, so that the outer edge radius of the annular stabilization plate 1 is roughly the same as the length of the barrel body, and the maximum All the soil that is prone to softening or liquefaction is covered under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com